Reverse logistics solutions focus on managing product returns, refurbishment, recycling, and disposal to improve sustainability and reduce costs in the supply chain. Warehouse automation enhances operational efficiency through robotics, AI-driven inventory management, and real-time data analytics, streamlining receiving, storage, and order fulfillment processes. Discover how integrating both strategies can optimize your logistics performance and drive competitive advantage.

Why it is important

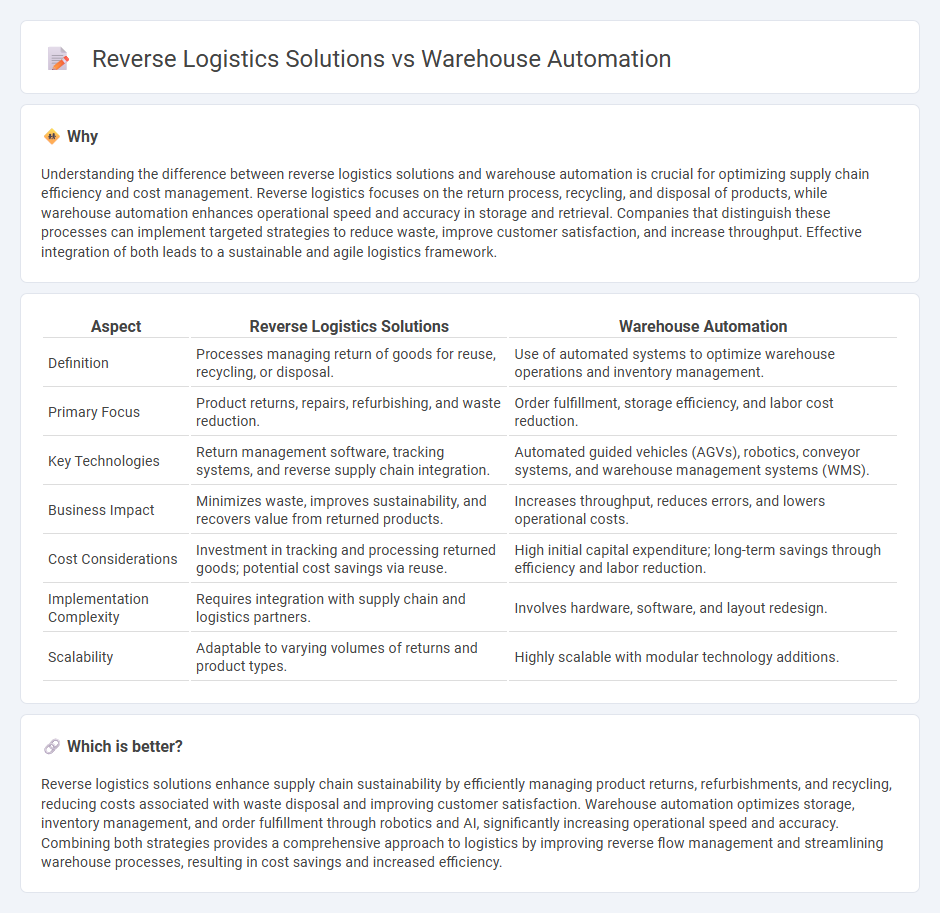

Understanding the difference between reverse logistics solutions and warehouse automation is crucial for optimizing supply chain efficiency and cost management. Reverse logistics focuses on the return process, recycling, and disposal of products, while warehouse automation enhances operational speed and accuracy in storage and retrieval. Companies that distinguish these processes can implement targeted strategies to reduce waste, improve customer satisfaction, and increase throughput. Effective integration of both leads to a sustainable and agile logistics framework.

Comparison Table

| Aspect | Reverse Logistics Solutions | Warehouse Automation |

|---|---|---|

| Definition | Processes managing return of goods for reuse, recycling, or disposal. | Use of automated systems to optimize warehouse operations and inventory management. |

| Primary Focus | Product returns, repairs, refurbishing, and waste reduction. | Order fulfillment, storage efficiency, and labor cost reduction. |

| Key Technologies | Return management software, tracking systems, and reverse supply chain integration. | Automated guided vehicles (AGVs), robotics, conveyor systems, and warehouse management systems (WMS). |

| Business Impact | Minimizes waste, improves sustainability, and recovers value from returned products. | Increases throughput, reduces errors, and lowers operational costs. |

| Cost Considerations | Investment in tracking and processing returned goods; potential cost savings via reuse. | High initial capital expenditure; long-term savings through efficiency and labor reduction. |

| Implementation Complexity | Requires integration with supply chain and logistics partners. | Involves hardware, software, and layout redesign. |

| Scalability | Adaptable to varying volumes of returns and product types. | Highly scalable with modular technology additions. |

Which is better?

Reverse logistics solutions enhance supply chain sustainability by efficiently managing product returns, refurbishments, and recycling, reducing costs associated with waste disposal and improving customer satisfaction. Warehouse automation optimizes storage, inventory management, and order fulfillment through robotics and AI, significantly increasing operational speed and accuracy. Combining both strategies provides a comprehensive approach to logistics by improving reverse flow management and streamlining warehouse processes, resulting in cost savings and increased efficiency.

Connection

Reverse logistics solutions enhance warehouse automation by streamlining the process of returning, sorting, and refurbishing products, which reduces manual labor and processing times. Automated systems such as robotic sorting, inventory tracking, and automated guided vehicles (AGVs) integrate with reverse logistics workflows to improve accuracy and efficiency. This connection reduces operational costs, minimizes errors, and accelerates the return-to-stock cycle in supply chain management.

Key Terms

**Warehouse Automation:**

Warehouse automation enhances operational efficiency through robotics, automated guided vehicles (AGVs), and advanced inventory management systems, significantly reducing labor costs and errors. These technologies enable faster order fulfillment and real-time inventory tracking, increasing overall supply chain responsiveness. Explore how warehouse automation transforms logistics by boosting productivity and accuracy.

Robotics

Warehouse automation leverages robotics to streamline inventory management, picking, packing, and shipping processes, significantly improving operational efficiency. Reverse logistics solutions also employ robotics, but focus on handling returns, refurbishment, and recycling to minimize waste and maximize asset recovery. Explore more to understand how robotics transform both forward and reverse supply chain operations.

Automated Storage and Retrieval Systems (AS/RS)

Automated Storage and Retrieval Systems (AS/RS) enhance warehouse automation by increasing storage density and accelerating inventory retrieval processes, significantly improving operational efficiency. In reverse logistics, AS/RS facilitate the efficient handling of returned goods, enabling faster inspection, sorting, and restocking, thus minimizing delays and reducing labor costs. Discover how integrating AS/RS transforms both warehouse automation and reverse logistics through cutting-edge technology and optimized workflows.

Source and External Links

Warehouse Automation Explained: Trends, Types & Best Practices - Warehouse automation automates the movement of inventory with minimal human assistance through a process involving an implementation committee, data collection, inventory control evaluation, warehouse management systems, and choosing suitable automation types aligned to goals.

13 Warehouse Automation Trends in 2025 - Conger Industries - Implementing warehouse automation requires preparation such as conducting feasibility studies, defining clear objectives, budgeting, involving stakeholders, and selecting appropriate hardware and software solutions like automated storage systems and autonomous mobile robots integrated with WMS or ERP.

Warehouse Automation | SSI SCHAEFER - Warehouse automation integrates hardware, software, and control systems like conveyors, sorting machines, robotics, and AS/RS to optimize inventory management, order fulfillment, and material handling by reducing manual labor, minimizing errors, and improving efficiency in supply chains.

dowidth.com

dowidth.com