Drop shipping minimizes inventory costs by shipping products directly from suppliers to customers, enhancing flexibility and reducing upfront investment. Vendor-managed inventory (VMI) improves supply chain efficiency by allowing suppliers to manage inventory levels at the retailer's location, optimizing stock availability and reducing stockouts. Explore the benefits and challenges of drop shipping versus VMI to determine which logistics strategy suits your business needs.

Why it is important

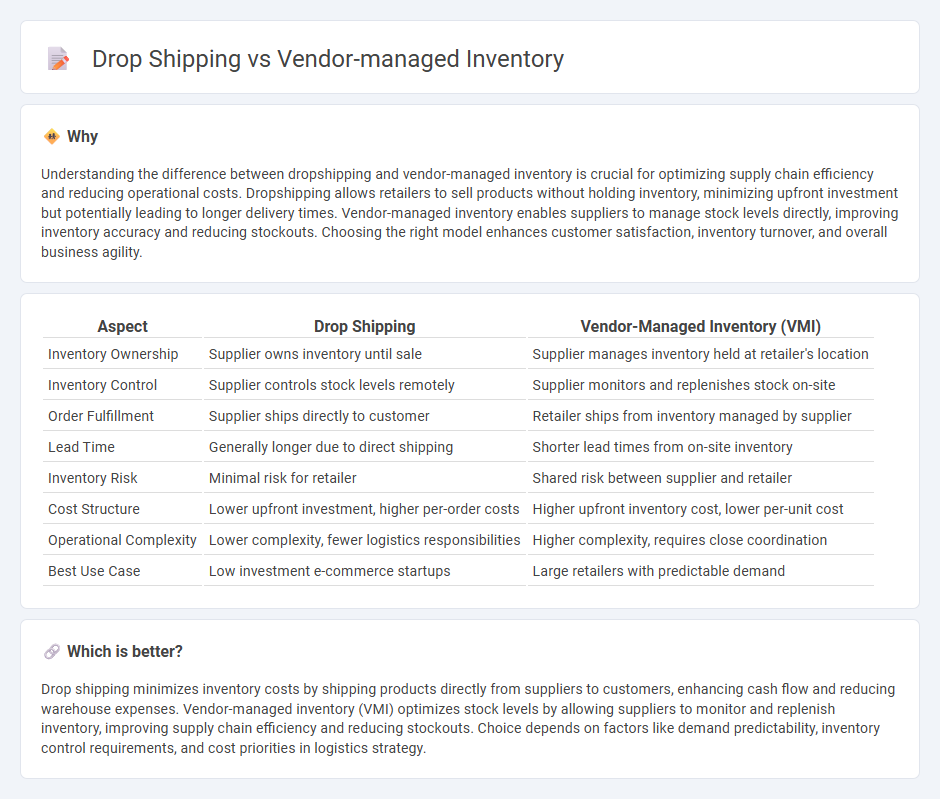

Understanding the difference between dropshipping and vendor-managed inventory is crucial for optimizing supply chain efficiency and reducing operational costs. Dropshipping allows retailers to sell products without holding inventory, minimizing upfront investment but potentially leading to longer delivery times. Vendor-managed inventory enables suppliers to manage stock levels directly, improving inventory accuracy and reducing stockouts. Choosing the right model enhances customer satisfaction, inventory turnover, and overall business agility.

Comparison Table

| Aspect | Drop Shipping | Vendor-Managed Inventory (VMI) |

|---|---|---|

| Inventory Ownership | Supplier owns inventory until sale | Supplier manages inventory held at retailer's location |

| Inventory Control | Supplier controls stock levels remotely | Supplier monitors and replenishes stock on-site |

| Order Fulfillment | Supplier ships directly to customer | Retailer ships from inventory managed by supplier |

| Lead Time | Generally longer due to direct shipping | Shorter lead times from on-site inventory |

| Inventory Risk | Minimal risk for retailer | Shared risk between supplier and retailer |

| Cost Structure | Lower upfront investment, higher per-order costs | Higher upfront inventory cost, lower per-unit cost |

| Operational Complexity | Lower complexity, fewer logistics responsibilities | Higher complexity, requires close coordination |

| Best Use Case | Low investment e-commerce startups | Large retailers with predictable demand |

Which is better?

Drop shipping minimizes inventory costs by shipping products directly from suppliers to customers, enhancing cash flow and reducing warehouse expenses. Vendor-managed inventory (VMI) optimizes stock levels by allowing suppliers to monitor and replenish inventory, improving supply chain efficiency and reducing stockouts. Choice depends on factors like demand predictability, inventory control requirements, and cost priorities in logistics strategy.

Connection

Drop shipping and vendor-managed inventory (VMI) are connected through their focus on streamlining supply chain management by reducing inventory holding costs and improving order fulfillment speed. Both models rely heavily on real-time data sharing between retailers and suppliers to optimize inventory levels and meet customer demand efficiently. Integration of these systems enhances visibility and coordination, minimizing stockouts and excess inventory while accelerating delivery times.

Key Terms

Inventory Ownership

Vendor-managed inventory (VMI) places inventory ownership and management responsibility with the supplier, who monitors stock levels and replenishes as needed within the retailer's premises, optimizing inventory turnover and reducing stockouts. Drop shipping transfers inventory ownership entirely to the supplier, with products shipped directly to customers, eliminating the need for retailers to hold stock but potentially impacting control over availability and delivery times. Explore detailed comparisons to determine the best inventory strategy for your business needs.

Order Fulfillment

Vendor-managed inventory (VMI) involves suppliers managing stock levels at the retailer's location, ensuring real-time replenishment and streamlined order fulfillment processes to reduce stockouts and carrying costs. Drop shipping, on the other hand, directly ships products from supplier to customer, minimizing inventory holding but potentially increasing delivery times and complicating quality control. Explore deeper insights on how to optimize order fulfillment strategies for your business.

Stock Replenishment

Vendor-managed inventory (VMI) streamlines stock replenishment by shifting inventory control responsibility to the supplier, ensuring real-time stock level monitoring and automated replenishment based on actual sales data. Drop shipping eliminates the need for retailers to hold inventory, as suppliers ship products directly to customers, though this can lead to longer delivery times and less control over stock levels. Explore detailed insights to determine which stock replenishment strategy best aligns with your supply chain goals.

Source and External Links

Vendor Managed Inventory: Definition, Benefits, and ... - VMI is a business model where the supplier manages and replenishes inventory based on demand data from the buyer to optimize stock levels, reduce shortages, and minimize excess inventory.

What is VMI? Vendor Managed Inventory Advantages and ... - VMI involves vendors managing their inventory located at the buyer's site by monitoring sales and inventory levels and making replenishment decisions based on agreed metrics and demand forecasting.

What Is Vendor-Managed Inventory (VMI)? - VMI is a supply chain strategy in which suppliers use real-time sales and stock information to proactively manage inventory levels, reducing stockouts and freeing customers from inventory responsibilities.

dowidth.com

dowidth.com