Predictive fleet maintenance leverages real-time data analytics and IoT sensors to forecast vehicle issues before failures occur, enhancing fleet uptime and reducing repair costs. Order fulfillment focuses on the efficient processing, packing, and delivery of goods to meet customer demands swiftly, often utilizing automation and inventory management systems. Explore how integrating predictive maintenance with streamlined order fulfillment can optimize logistics operations.

Why it is important

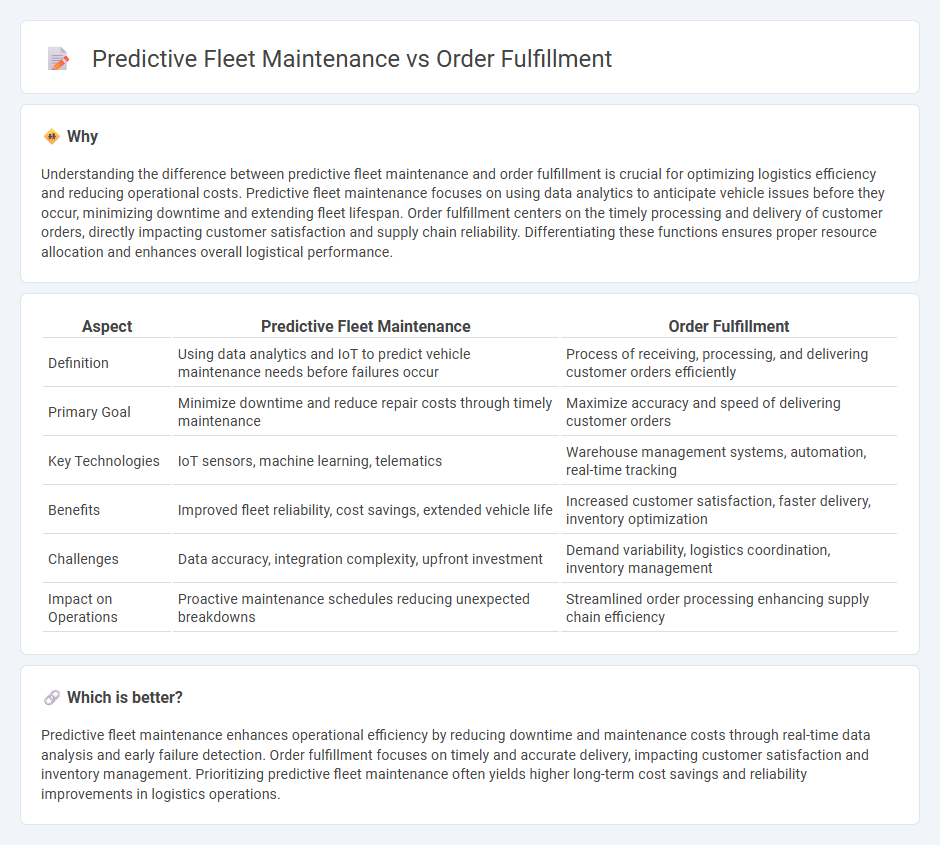

Understanding the difference between predictive fleet maintenance and order fulfillment is crucial for optimizing logistics efficiency and reducing operational costs. Predictive fleet maintenance focuses on using data analytics to anticipate vehicle issues before they occur, minimizing downtime and extending fleet lifespan. Order fulfillment centers on the timely processing and delivery of customer orders, directly impacting customer satisfaction and supply chain reliability. Differentiating these functions ensures proper resource allocation and enhances overall logistical performance.

Comparison Table

| Aspect | Predictive Fleet Maintenance | Order Fulfillment |

|---|---|---|

| Definition | Using data analytics and IoT to predict vehicle maintenance needs before failures occur | Process of receiving, processing, and delivering customer orders efficiently |

| Primary Goal | Minimize downtime and reduce repair costs through timely maintenance | Maximize accuracy and speed of delivering customer orders |

| Key Technologies | IoT sensors, machine learning, telematics | Warehouse management systems, automation, real-time tracking |

| Benefits | Improved fleet reliability, cost savings, extended vehicle life | Increased customer satisfaction, faster delivery, inventory optimization |

| Challenges | Data accuracy, integration complexity, upfront investment | Demand variability, logistics coordination, inventory management |

| Impact on Operations | Proactive maintenance schedules reducing unexpected breakdowns | Streamlined order processing enhancing supply chain efficiency |

Which is better?

Predictive fleet maintenance enhances operational efficiency by reducing downtime and maintenance costs through real-time data analysis and early failure detection. Order fulfillment focuses on timely and accurate delivery, impacting customer satisfaction and inventory management. Prioritizing predictive fleet maintenance often yields higher long-term cost savings and reliability improvements in logistics operations.

Connection

Predictive fleet maintenance enhances order fulfillment by minimizing vehicle downtime, ensuring timely deliveries and optimizing route efficiency. Accurate data from vehicle sensors allows logistics managers to anticipate maintenance needs, reducing unexpected breakdowns that can delay shipments. This seamless integration supports higher customer satisfaction and operational cost savings across supply chain operations.

Key Terms

Order Fulfillment:

Order fulfillment encompasses the entire process of receiving, processing, and delivering customer orders accurately and on time, directly impacting customer satisfaction and operational efficiency. Key components include inventory management, order processing, picking, packing, and shipping, all coordinated to minimize delays and errors. Explore advanced strategies and technologies to optimize order fulfillment and enhance supply chain performance.

Picking and Packing

Order fulfillment in picking and packing emphasizes accuracy and speed to ensure timely delivery and customer satisfaction, leveraging barcode scanning and real-time inventory updates. Predictive fleet maintenance enhances operational efficiency by using IoT sensors and data analytics to anticipate vehicle breakdowns, reducing downtime and optimizing delivery schedules. Explore how integrating these strategies can streamline your logistics processes and boost performance.

Order Accuracy

Order accuracy is critical in order fulfillment, ensuring customers receive the correct products promptly, which directly impacts customer satisfaction and repeat business. Predictive fleet maintenance indirectly supports order accuracy by minimizing vehicle breakdowns and delivery delays, enabling timely and precise deliveries. Explore how optimizing both processes can enhance your supply chain efficiency and customer experience.

Source and External Links

Order Fulfillment: Meaning, Process, and How To Optimize - Order fulfillment is the process of receiving and processing customer orders, packaging and shipping products, and providing tracking information, with common steps including receiving customer info, storage of items, and order processing to ensure accurate shipping.

Order Fulfillment Process: Definition and 7 Key Steps - The order fulfillment process involves seven key steps such as receiving inventory, storing inventory, order processing, packing, shipping, delivery, and handling returns to ensure timely and accurate delivery to customers.

What Is Order Fulfillment? Improve Your Process & Strategy - Order fulfillment covers the entire journey from a customer placing an order to the product's delivery, encompassing inventory receiving, quality checks, order picking, packaging, shipping, and customer communication.

dowidth.com

dowidth.com