Milk run delivery streamlines logistics by using a single vehicle to collect goods from multiple suppliers and deliver them directly to a manufacturing facility, reducing transportation costs and inventory levels. Pool distribution consolidates shipments from various suppliers at a central hub before distributing them to final destinations, optimizing load capacity and minimizing transit times. Explore more to understand which strategy best enhances efficiency in your supply chain.

Why it is important

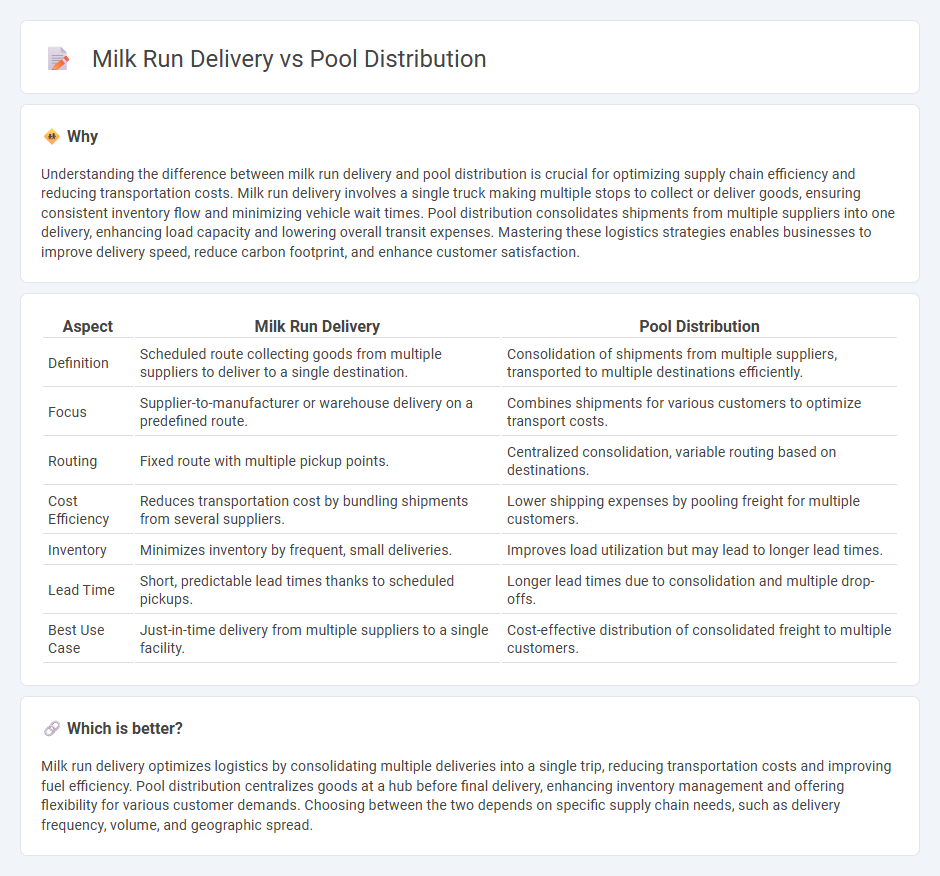

Understanding the difference between milk run delivery and pool distribution is crucial for optimizing supply chain efficiency and reducing transportation costs. Milk run delivery involves a single truck making multiple stops to collect or deliver goods, ensuring consistent inventory flow and minimizing vehicle wait times. Pool distribution consolidates shipments from multiple suppliers into one delivery, enhancing load capacity and lowering overall transit expenses. Mastering these logistics strategies enables businesses to improve delivery speed, reduce carbon footprint, and enhance customer satisfaction.

Comparison Table

| Aspect | Milk Run Delivery | Pool Distribution |

|---|---|---|

| Definition | Scheduled route collecting goods from multiple suppliers to deliver to a single destination. | Consolidation of shipments from multiple suppliers, transported to multiple destinations efficiently. |

| Focus | Supplier-to-manufacturer or warehouse delivery on a predefined route. | Combines shipments for various customers to optimize transport costs. |

| Routing | Fixed route with multiple pickup points. | Centralized consolidation, variable routing based on destinations. |

| Cost Efficiency | Reduces transportation cost by bundling shipments from several suppliers. | Lower shipping expenses by pooling freight for multiple customers. |

| Inventory | Minimizes inventory by frequent, small deliveries. | Improves load utilization but may lead to longer lead times. |

| Lead Time | Short, predictable lead times thanks to scheduled pickups. | Longer lead times due to consolidation and multiple drop-offs. |

| Best Use Case | Just-in-time delivery from multiple suppliers to a single facility. | Cost-effective distribution of consolidated freight to multiple customers. |

Which is better?

Milk run delivery optimizes logistics by consolidating multiple deliveries into a single trip, reducing transportation costs and improving fuel efficiency. Pool distribution centralizes goods at a hub before final delivery, enhancing inventory management and offering flexibility for various customer demands. Choosing between the two depends on specific supply chain needs, such as delivery frequency, volume, and geographic spread.

Connection

Milk run delivery and pool distribution optimize supply chain efficiency by consolidating shipments from multiple suppliers into a single trip, reducing transportation costs and minimizing carbon emissions. Milk run systems enable frequent, scheduled pickups, ensuring timely delivery to a central pool distribution hub where goods are sorted and dispatched to their final destinations. Together, these strategies enhance inventory management and improve overall logistics coordination.

Key Terms

Consolidation

Pool distribution consolidates shipments from multiple suppliers at a central hub, optimizing load capacity and reducing transportation costs through efficient route planning. Milk run delivery follows a fixed route to collect or deliver smaller loads from multiple locations, ensuring timely and consistent shipments while minimizing inventory levels. Explore the advantages of each method to enhance your supply chain consolidation strategy.

Route Optimization

Pool distribution consolidates shipments from multiple suppliers to optimize delivery routes, reducing transportation costs and improving load efficiency. Milk run delivery follows a fixed loop, collecting goods from various suppliers and returning to the distribution center, which enhances route consistency and minimizes empty miles. Explore more about how route optimization transforms supply chain efficiency.

Drop-off Points

Pool distribution consolidates shipments from multiple suppliers into a single vehicle, optimizing route efficiency by delivering to designated drop-off points where recipients pick up their goods. Milk run delivery involves a scheduled route with frequent stops, ensuring timely and consistent delivery directly to multiple drop-off points within a network. Explore the impact of drop-off strategies on supply chain efficiency and cost reduction to understand which method suits your logistics needs best.

Source and External Links

Pool Distribution - Pool distribution consolidates multiple orders destined for the same geographic area into a single shipment to regional cross-dock terminals for sorting and final delivery, reducing transportation costs and improving efficiency.

Pool Distribution Services in the Mid-Atlantic, Northeast & ... - Pool distribution programs supply multiple locations from regional warehouses, offering retailers and distributors cost savings, improved service, and complete visibility with advanced technology.

What is Pool Distribution? - Pool distribution is a shipping method where multiple shipments heading to a specific region are consolidated into one truckload and delivered from a regional terminal to individual destinations, maximizing truck space and shipping efficiency.

dowidth.com

dowidth.com