Cold chain traceability focuses on monitoring temperature-sensitive products throughout the transportation and storage process to ensure quality and compliance with safety standards. Supply chain visibility provides a broader real-time overview of all logistics activities, enabling comprehensive tracking of goods, inventory levels, and shipment statuses across multiple stakeholders. Explore how integrating cold chain traceability with supply chain visibility can optimize operational efficiency and product integrity.

Why it is important

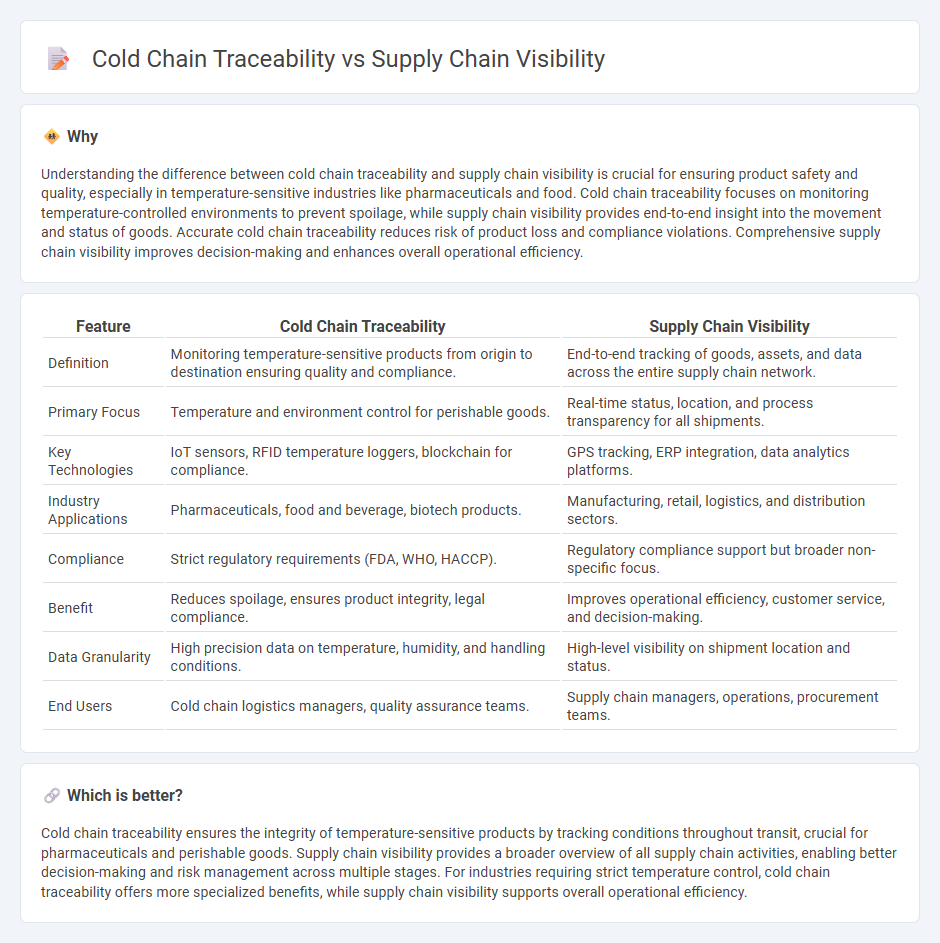

Understanding the difference between cold chain traceability and supply chain visibility is crucial for ensuring product safety and quality, especially in temperature-sensitive industries like pharmaceuticals and food. Cold chain traceability focuses on monitoring temperature-controlled environments to prevent spoilage, while supply chain visibility provides end-to-end insight into the movement and status of goods. Accurate cold chain traceability reduces risk of product loss and compliance violations. Comprehensive supply chain visibility improves decision-making and enhances overall operational efficiency.

Comparison Table

| Feature | Cold Chain Traceability | Supply Chain Visibility |

|---|---|---|

| Definition | Monitoring temperature-sensitive products from origin to destination ensuring quality and compliance. | End-to-end tracking of goods, assets, and data across the entire supply chain network. |

| Primary Focus | Temperature and environment control for perishable goods. | Real-time status, location, and process transparency for all shipments. |

| Key Technologies | IoT sensors, RFID temperature loggers, blockchain for compliance. | GPS tracking, ERP integration, data analytics platforms. |

| Industry Applications | Pharmaceuticals, food and beverage, biotech products. | Manufacturing, retail, logistics, and distribution sectors. |

| Compliance | Strict regulatory requirements (FDA, WHO, HACCP). | Regulatory compliance support but broader non-specific focus. |

| Benefit | Reduces spoilage, ensures product integrity, legal compliance. | Improves operational efficiency, customer service, and decision-making. |

| Data Granularity | High precision data on temperature, humidity, and handling conditions. | High-level visibility on shipment location and status. |

| End Users | Cold chain logistics managers, quality assurance teams. | Supply chain managers, operations, procurement teams. |

Which is better?

Cold chain traceability ensures the integrity of temperature-sensitive products by tracking conditions throughout transit, crucial for pharmaceuticals and perishable goods. Supply chain visibility provides a broader overview of all supply chain activities, enabling better decision-making and risk management across multiple stages. For industries requiring strict temperature control, cold chain traceability offers more specialized benefits, while supply chain visibility supports overall operational efficiency.

Connection

Cold chain traceability relies heavily on supply chain visibility to monitor and record temperature-sensitive goods throughout the entire logistics process. Real-time tracking systems and IoT sensors provide critical data that ensures cold chain compliance and reduces spoilage risks. Enhanced supply chain visibility enables proactive decision-making, optimizing cold storage conditions and delivery schedules for perishable products.

Key Terms

Supply Chain Visibility:

Supply chain visibility refers to the real-time tracking and monitoring of inventory, shipments, and processes across the entire supply network, enabling proactive decision-making and operational efficiency. It encompasses end-to-end data integration from suppliers, manufacturers, warehouses, and distributors to ensure transparency and reduce risks such as delays or stockouts. Explore how advanced technologies like IoT and blockchain enhance supply chain visibility for improved performance and customer satisfaction.

Real-time Tracking

Real-time tracking enhances supply chain visibility by providing continuous data on shipment locations, conditions, and estimated arrival times, enabling proactive decision-making and reducing delays. In cold chain traceability, it specifically monitors temperature-sensitive goods, ensuring compliance with safety standards and maintaining product integrity throughout transit. Explore how integrating real-time tracking technology can optimize both supply chain visibility and cold chain traceability for improved operational efficiency.

Inventory Management

Supply chain visibility provides real-time insights into the location and status of inventory across the entire supply network, enabling better demand forecasting and reduced stockouts. Cold chain traceability specifically ensures the monitoring of temperature-sensitive goods, maintaining compliance with regulatory standards and preserving product quality throughout storage and transportation. Discover how integrating advanced tracking technologies optimizes inventory management for both general supply chains and cold chain operations.

Source and External Links

What is Supply Chain Visibility? - Tibco - Supply chain visibility tracks a product from raw materials through manufacturing to customers, enabling organizations to identify delays and inefficiencies by accessing unified data across the entire supply chain.

What Is Supply Chain Visibility (SCV)? Definition & Examples - Supply chain visibility is the transparency to track individual components and finished products throughout the supply chain, allowing companies to monitor inventory, certifications, locations, and status in real time for better problem-solving and efficiency.

What is Supply Chain Visibility? Meaning and Definition - GEP - It is the ability to view or track inventory movement end-to-end in real time, enabling optimized inventory, better risk management, and more responsive supply chains via AI-powered platforms.

dowidth.com

dowidth.com