Silent delivery offers a discreet and secure approach to shipping by minimizing visible packaging and notifications, enhancing customer privacy and satisfaction during last-mile logistics. Hub-and-spoke distribution optimizes transportation efficiency by consolidating goods at central hubs before dispatching to various spokes or delivery points, reducing costs and improving inventory management. Explore the advantages and applications of these logistics models to optimize your supply chain strategy.

Why it is important

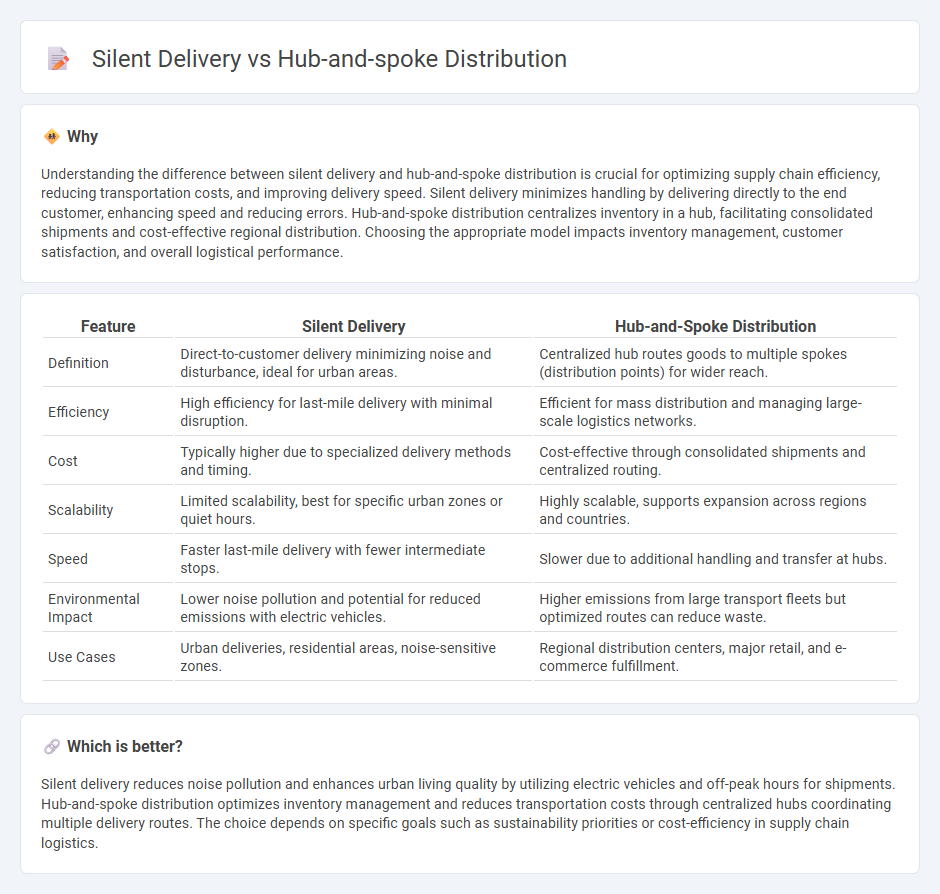

Understanding the difference between silent delivery and hub-and-spoke distribution is crucial for optimizing supply chain efficiency, reducing transportation costs, and improving delivery speed. Silent delivery minimizes handling by delivering directly to the end customer, enhancing speed and reducing errors. Hub-and-spoke distribution centralizes inventory in a hub, facilitating consolidated shipments and cost-effective regional distribution. Choosing the appropriate model impacts inventory management, customer satisfaction, and overall logistical performance.

Comparison Table

| Feature | Silent Delivery | Hub-and-Spoke Distribution |

|---|---|---|

| Definition | Direct-to-customer delivery minimizing noise and disturbance, ideal for urban areas. | Centralized hub routes goods to multiple spokes (distribution points) for wider reach. |

| Efficiency | High efficiency for last-mile delivery with minimal disruption. | Efficient for mass distribution and managing large-scale logistics networks. |

| Cost | Typically higher due to specialized delivery methods and timing. | Cost-effective through consolidated shipments and centralized routing. |

| Scalability | Limited scalability, best for specific urban zones or quiet hours. | Highly scalable, supports expansion across regions and countries. |

| Speed | Faster last-mile delivery with fewer intermediate stops. | Slower due to additional handling and transfer at hubs. |

| Environmental Impact | Lower noise pollution and potential for reduced emissions with electric vehicles. | Higher emissions from large transport fleets but optimized routes can reduce waste. |

| Use Cases | Urban deliveries, residential areas, noise-sensitive zones. | Regional distribution centers, major retail, and e-commerce fulfillment. |

Which is better?

Silent delivery reduces noise pollution and enhances urban living quality by utilizing electric vehicles and off-peak hours for shipments. Hub-and-spoke distribution optimizes inventory management and reduces transportation costs through centralized hubs coordinating multiple delivery routes. The choice depends on specific goals such as sustainability priorities or cost-efficiency in supply chain logistics.

Connection

Silent delivery enhances hub-and-spoke distribution by minimizing noise pollution during the final last-mile transport from centralized hubs to end customers, improving urban logistics efficiency. Integrating electric or quiet vehicles in silent delivery supports the hub-and-spoke model's goal of reducing transit time and operational costs through streamlined, low-impact distribution channels. This synergy promotes sustainable logistics, meeting environmental regulations and increasing community acceptance in densely populated areas.

Key Terms

**Hub-and-Spoke Distribution:**

Hub-and-spoke distribution centralizes inventory in a main hub, streamlining order processing and enabling efficient shipment to multiple regional spokes. This model reduces transportation costs, improves inventory management, and enhances delivery speed by consolidating shipments at the hub before dispatching to end destinations. Explore the advantages of hub-and-spoke distribution to optimize your supply chain efficiency.

Centralized Hub

Centralized hub distribution consolidates inventory and shipping operations into a single, centralized location, improving efficiency through streamlined order processing and reduced transportation costs. This model contrasts with silent delivery, which emphasizes discrete, often decentralized shipment methods to minimize customer noise or disruption. Explore the advantages and practical applications of centralized hubs to optimize your supply chain management.

Spoke Routes

Spoke routes in hub-and-spoke distribution streamline delivery by centralizing goods at a hub before dispatching to spokes, optimizing route efficiency and reducing transportation costs. Silent delivery minimizes customer interaction during the final mile, enhancing contactless service and operational speed on spoke routes. Explore more insights on optimizing spoke route logistics and delivery methods.

Source and External Links

Hub and Spoke Model In Logistics And Its Importance - The hub-and-spoke distribution model simplifies supply chains by centralizing goods in one hub, optimizing delivery routes to multiple destinations, reducing costs, and enhancing workforce productivity and delivery speed compared to point-to-point models.

Hub-and-Spoke Model: Reinventing Your Logistics in 2024 - This model lowers transit times, improves service levels by positioning inventory closer to consumers, helps control last-mile delivery costs, and increases overall logistics efficiency by managing operations from a central hub.

Spoke-hub distribution paradigm - Also known as the hub-and-spoke system, this transport optimization organizes routes as spokes connecting outlying points to a central hub, widely used since the 1950s in aviation and later adopted by logistics and telecommunications to improve network efficiency.

dowidth.com

dowidth.com