Quick commerce accelerates delivery times by leveraging localized inventory and advanced routing algorithms to fulfill customer orders within minutes. Inventory management focuses on optimizing stock levels and warehouse operations to reduce costs and prevent stockouts. Explore how integrating both strategies can transform your supply chain efficiency.

Why it is important

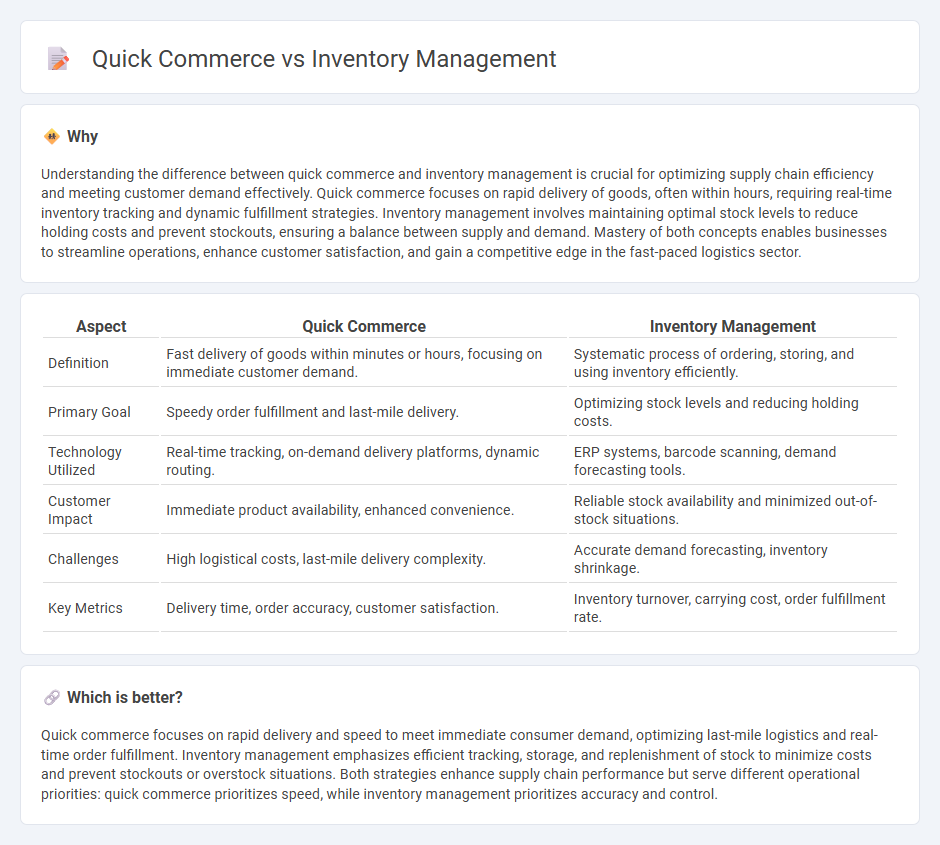

Understanding the difference between quick commerce and inventory management is crucial for optimizing supply chain efficiency and meeting customer demand effectively. Quick commerce focuses on rapid delivery of goods, often within hours, requiring real-time inventory tracking and dynamic fulfillment strategies. Inventory management involves maintaining optimal stock levels to reduce holding costs and prevent stockouts, ensuring a balance between supply and demand. Mastery of both concepts enables businesses to streamline operations, enhance customer satisfaction, and gain a competitive edge in the fast-paced logistics sector.

Comparison Table

| Aspect | Quick Commerce | Inventory Management |

|---|---|---|

| Definition | Fast delivery of goods within minutes or hours, focusing on immediate customer demand. | Systematic process of ordering, storing, and using inventory efficiently. |

| Primary Goal | Speedy order fulfillment and last-mile delivery. | Optimizing stock levels and reducing holding costs. |

| Technology Utilized | Real-time tracking, on-demand delivery platforms, dynamic routing. | ERP systems, barcode scanning, demand forecasting tools. |

| Customer Impact | Immediate product availability, enhanced convenience. | Reliable stock availability and minimized out-of-stock situations. |

| Challenges | High logistical costs, last-mile delivery complexity. | Accurate demand forecasting, inventory shrinkage. |

| Key Metrics | Delivery time, order accuracy, customer satisfaction. | Inventory turnover, carrying cost, order fulfillment rate. |

Which is better?

Quick commerce focuses on rapid delivery and speed to meet immediate consumer demand, optimizing last-mile logistics and real-time order fulfillment. Inventory management emphasizes efficient tracking, storage, and replenishment of stock to minimize costs and prevent stockouts or overstock situations. Both strategies enhance supply chain performance but serve different operational priorities: quick commerce prioritizes speed, while inventory management prioritizes accuracy and control.

Connection

Quick commerce relies heavily on efficient inventory management to meet consumer demands for fast delivery times, often within minutes. Real-time inventory tracking and accurate stock forecasting ensure product availability and reduce stockouts, which is crucial for maintaining service speed in quick commerce. Advanced inventory management systems enable seamless coordination between warehouses and last-mile delivery, optimizing logistics operations and enhancing customer satisfaction.

Key Terms

**Inventory Management:**

Inventory management optimizes stock levels through real-time tracking and demand forecasting to reduce holding costs and prevent stockouts. Advanced inventory software integrates with supply chain systems to enhance order accuracy and streamline replenishment processes. Learn more about how effective inventory management drives profitability and operational efficiency in quick commerce.

Stock Replenishment

Inventory management systems optimize stock levels by tracking real-time demand and sales patterns, ensuring accurate stock replenishment and minimizing overstock or stockouts. Quick commerce relies on rapid restocking processes supported by robust inventory analytics to meet the high-frequency, short fulfillment windows characteristic of on-demand delivery models. Explore how integrating advanced stock replenishment techniques can boost efficiency in both inventory management and quick commerce operations.

Safety Stock

Safety stock plays a critical role in both inventory management and quick commerce by cushioning against demand variability and supply chain disruptions. While traditional inventory management relies on calculated safety stock levels to optimize storage costs and service levels, quick commerce demands more dynamic and responsive safety stock strategies to ensure rapid fulfillment and customer satisfaction. Explore the latest approaches to safety stock optimization tailored for evolving retail models.

Source and External Links

What Is Inventory Management? Benefits, Types, & Techniques - Inventory management is the process of tracking and controlling the flow of goods--from raw materials to finished products--through demand planning, ordering, delivery, tracking and storage, sales, review, and replenishment to optimize supply chains and reduce costs.

Inventory Management Guide + Methods & Examples - Extensiv - Inventory management systems ensure optimal stock levels using methods such as spreadsheets, automated real-time tracking with RFID, ERP software integration, and multichannel management across warehouses and sales platforms.

Inventory Management: How it Works and Tools (2025) - Shopify - Inventory management involves overseeing and controlling the movement of raw goods, work-in-progress, finished goods, and maintenance items to minimize holding costs and ensure timely replenishment for efficient customer fulfillment.

dowidth.com

dowidth.com