Supply chain control towers provide centralized visibility and real-time data analytics to optimize end-to-end logistics operations, enhancing decision-making and efficiency. Reverse logistics focuses on managing the return, refurbishment, and recycling of products, aiming to minimize waste and recover value from returned goods. Explore the differences and benefits of these logistics strategies to improve your supply chain management.

Why it is important

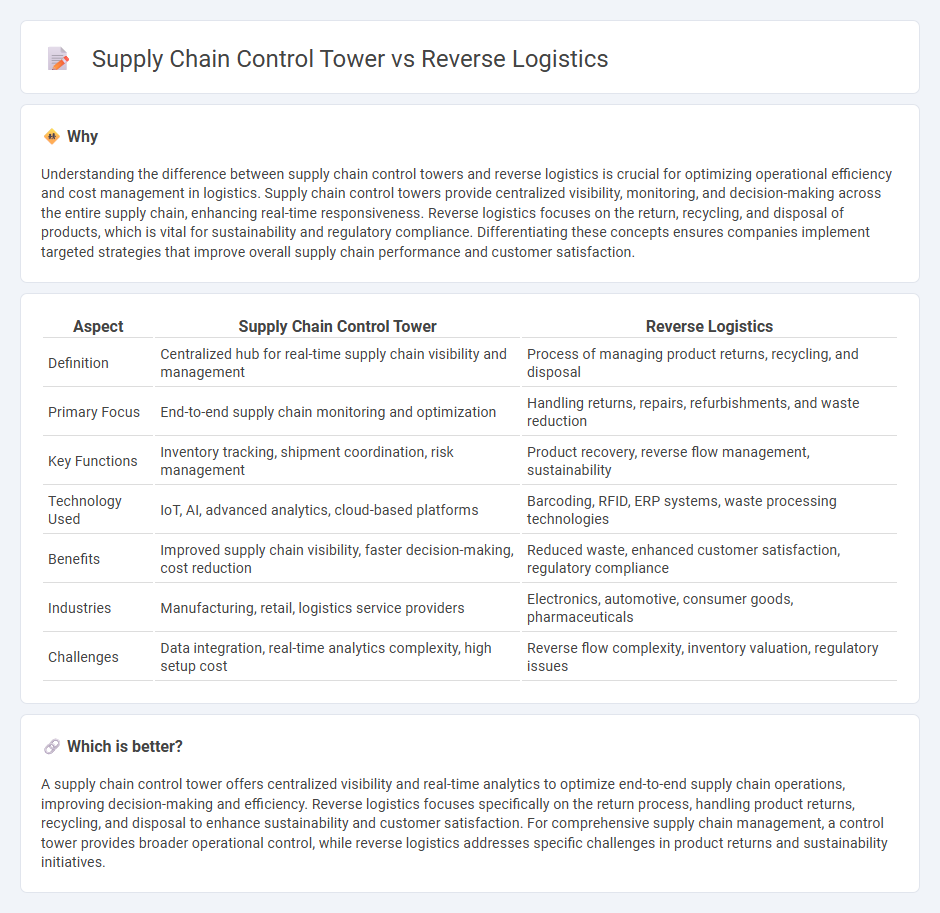

Understanding the difference between supply chain control towers and reverse logistics is crucial for optimizing operational efficiency and cost management in logistics. Supply chain control towers provide centralized visibility, monitoring, and decision-making across the entire supply chain, enhancing real-time responsiveness. Reverse logistics focuses on the return, recycling, and disposal of products, which is vital for sustainability and regulatory compliance. Differentiating these concepts ensures companies implement targeted strategies that improve overall supply chain performance and customer satisfaction.

Comparison Table

| Aspect | Supply Chain Control Tower | Reverse Logistics |

|---|---|---|

| Definition | Centralized hub for real-time supply chain visibility and management | Process of managing product returns, recycling, and disposal |

| Primary Focus | End-to-end supply chain monitoring and optimization | Handling returns, repairs, refurbishments, and waste reduction |

| Key Functions | Inventory tracking, shipment coordination, risk management | Product recovery, reverse flow management, sustainability |

| Technology Used | IoT, AI, advanced analytics, cloud-based platforms | Barcoding, RFID, ERP systems, waste processing technologies |

| Benefits | Improved supply chain visibility, faster decision-making, cost reduction | Reduced waste, enhanced customer satisfaction, regulatory compliance |

| Industries | Manufacturing, retail, logistics service providers | Electronics, automotive, consumer goods, pharmaceuticals |

| Challenges | Data integration, real-time analytics complexity, high setup cost | Reverse flow complexity, inventory valuation, regulatory issues |

Which is better?

A supply chain control tower offers centralized visibility and real-time analytics to optimize end-to-end supply chain operations, improving decision-making and efficiency. Reverse logistics focuses specifically on the return process, handling product returns, recycling, and disposal to enhance sustainability and customer satisfaction. For comprehensive supply chain management, a control tower provides broader operational control, while reverse logistics addresses specific challenges in product returns and sustainability initiatives.

Connection

Supply chain control towers enhance visibility and coordination across logistics networks, enabling real-time monitoring and efficient management of reverse logistics processes such as returns, recycling, and waste management. By integrating data from reverse logistics operations, control towers optimize inventory recovery, reduce costs, and improve sustainability outcomes. This connection supports agile decision-making and end-to-end supply chain resilience.

Key Terms

**Reverse Logistics:**

Reverse logistics involves managing the return flow of products from customers back to manufacturers or distribution centers for reuse, recycling, or disposal, optimizing cost-efficiency and sustainability. It plays a crucial role in closing the supply chain loop by reducing waste and recovering value from returned goods, ensuring compliance with environmental regulations. Explore how advanced reverse logistics solutions can enhance your supply chain resilience and sustainability efforts.

Returns Management

Reverse logistics centers on managing product returns, refurbishments, and recycling processes to optimize cost-efficiency and customer satisfaction. Supply chain control towers provide real-time visibility and centralized decision-making across the entire supply chain, enhancing coordination and response times for returns management. Discover how integrating reverse logistics with control tower technology can transform your returns strategy.

Remanufacturing

Reverse logistics involves the process of returning products from consumers back to manufacturers for remanufacturing, refurbishment, or recycling, focusing on sustainability and cost-efficiency. Supply chain control towers provide centralized visibility and real-time analytics across the entire supply chain, enabling better coordination of remanufacturing activities and resource optimization. Explore how integrating reverse logistics with supply chain control tower technology enhances remanufacturing performance and operational resilience.

Source and External Links

What is Reverse Logistics? - Reverse logistics is the process of moving goods from their final destination back to the manufacturer or distributor for return, repair, remanufacture, recycling, or disposal, and is essential for creating a leaner, more efficient supply chain aligned with sustainability goals.

A Guide to Reverse Logistics: How It Works, Types and ... - Reverse logistics manages the return of goods from customers to sellers or manufacturers, covering processes like returns authorization, scheduling shipments, refurbishments, and recycling across various industries.

Reverse logistics - Reverse logistics involves moving goods upstream in the supply chain for capturing value or proper disposal, including remanufacturing and refurbishing, with increasing importance due to environmental and green supply chain management practices.

dowidth.com

dowidth.com