Middle mile optimization enhances supply chain efficiency by streamlining transportation between suppliers and distribution centers, reducing transit times and costs through route planning and load consolidation. Inventory pooling centralizes stock across multiple locations to balance demand variability, lowering safety stock levels and minimizing holding expenses. Explore how integrating both strategies can significantly improve logistics performance and cost savings.

Why it is important

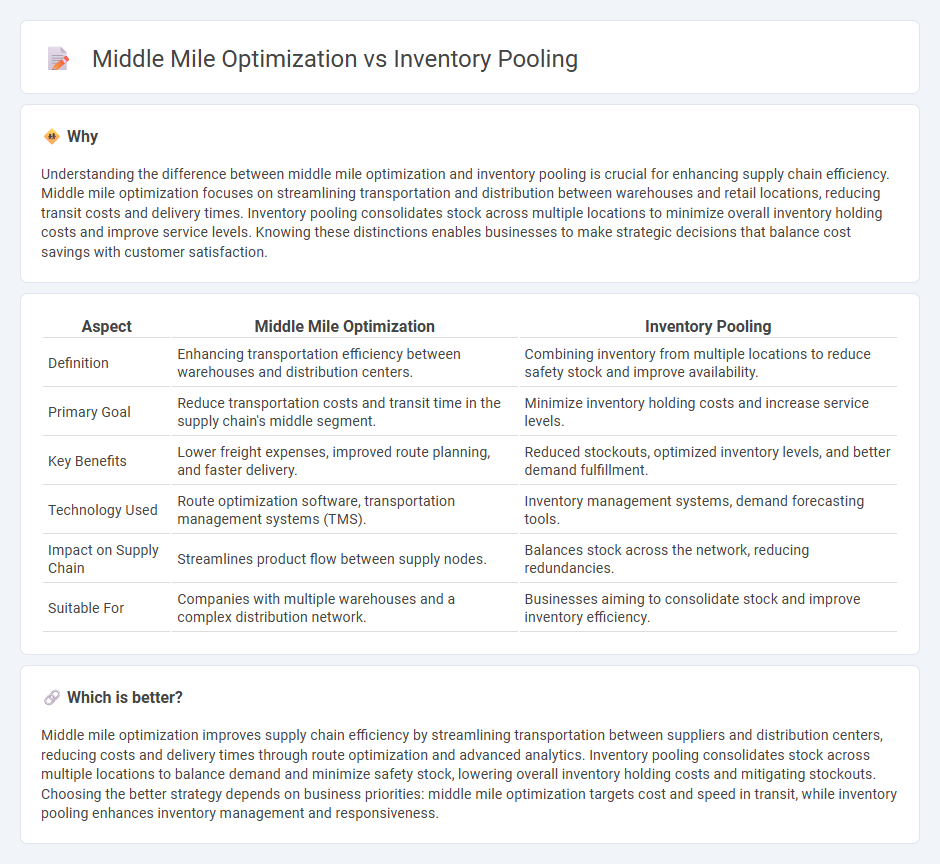

Understanding the difference between middle mile optimization and inventory pooling is crucial for enhancing supply chain efficiency. Middle mile optimization focuses on streamlining transportation and distribution between warehouses and retail locations, reducing transit costs and delivery times. Inventory pooling consolidates stock across multiple locations to minimize overall inventory holding costs and improve service levels. Knowing these distinctions enables businesses to make strategic decisions that balance cost savings with customer satisfaction.

Comparison Table

| Aspect | Middle Mile Optimization | Inventory Pooling |

|---|---|---|

| Definition | Enhancing transportation efficiency between warehouses and distribution centers. | Combining inventory from multiple locations to reduce safety stock and improve availability. |

| Primary Goal | Reduce transportation costs and transit time in the supply chain's middle segment. | Minimize inventory holding costs and increase service levels. |

| Key Benefits | Lower freight expenses, improved route planning, and faster delivery. | Reduced stockouts, optimized inventory levels, and better demand fulfillment. |

| Technology Used | Route optimization software, transportation management systems (TMS). | Inventory management systems, demand forecasting tools. |

| Impact on Supply Chain | Streamlines product flow between supply nodes. | Balances stock across the network, reducing redundancies. |

| Suitable For | Companies with multiple warehouses and a complex distribution network. | Businesses aiming to consolidate stock and improve inventory efficiency. |

Which is better?

Middle mile optimization improves supply chain efficiency by streamlining transportation between suppliers and distribution centers, reducing costs and delivery times through route optimization and advanced analytics. Inventory pooling consolidates stock across multiple locations to balance demand and minimize safety stock, lowering overall inventory holding costs and mitigating stockouts. Choosing the better strategy depends on business priorities: middle mile optimization targets cost and speed in transit, while inventory pooling enhances inventory management and responsiveness.

Connection

Middle mile optimization reduces transportation costs and transit times between distribution centers, directly enhancing inventory pooling efficiency by enabling faster, more reliable stock transfers. Inventory pooling consolidates stock at strategically located warehouses, leveraging optimized middle mile logistics to balance demand fluctuations across regions. This synergy minimizes overall inventory holding costs while improving order fulfillment speed and accuracy throughout the supply chain.

Key Terms

Risk Pooling

Inventory pooling reduces supply chain risk by consolidating stock across multiple locations, which minimizes demand variability and lowers safety stock requirements. Middle mile optimization enhances efficiency by streamlining transportation routes and delivery schedules between warehouses and distribution centers, but it does not directly address demand fluctuations. Explore how risk pooling can create resilient supply chains and improve inventory management strategies.

Cross-Docking

Inventory pooling reduces stock levels by consolidating inventory across multiple locations, improving service levels and lowering carrying costs. Middle mile optimization enhances transportation efficiency through strategic routing and cross-docking, minimizing delivery times and freight expenses. Explore how integrating cross-docking techniques can maximize supply chain agility and cost-effectiveness.

Demand Variability

Inventory pooling reduces demand variability by consolidating stock across multiple locations, enabling more efficient safety stock management and reducing total inventory levels. Middle mile optimization focuses on streamlining transportation and distribution processes to respond rapidly to fluctuating demand patterns, improving delivery speed and reducing operational costs. Discover how integrating these strategies can enhance supply chain resilience and responsiveness.

Source and External Links

Inventory Pooling: Strategies for Ecommerce Efficiency - ShipBob - Inventory pooling is an inventory management strategy where a brand maintains a central stock pool that serves multiple locations and sales channels, allowing better stock availability and lower warehousing costs by fulfilling all orders from a shared inventory source.

What Is Inventory Pooling? Key Benefits and Practices | Fulfyld - Inventory pooling consolidates inventory from multiple locations into a central distribution center to optimize inventory levels, reduce stockouts, minimize transportation costs, and improve operational efficiency, supported by advanced technology for real-time tracking and forecasting.

Inventory Pooling with Strategic Consumers: Operational and Behavioral Benefits - HBS - Beyond operational advantages, inventory pooling can affect consumer buying behavior by centralizing stock for multiple markets, which influences purchase timing and clearance sales strategies, benefiting firms especially with high-margin products and negatively correlated demand across markets.

dowidth.com

dowidth.com