Last yard delivery focuses on the final stage of the supply chain, ensuring products reach customers quickly and efficiently from local distribution centers. Reverse logistics deals with the process of returning goods, managing returns, repairs, and recycling to optimize sustainability and reduce costs. Discover how mastering both strategies can enhance operational efficiency and customer satisfaction.

Why it is important

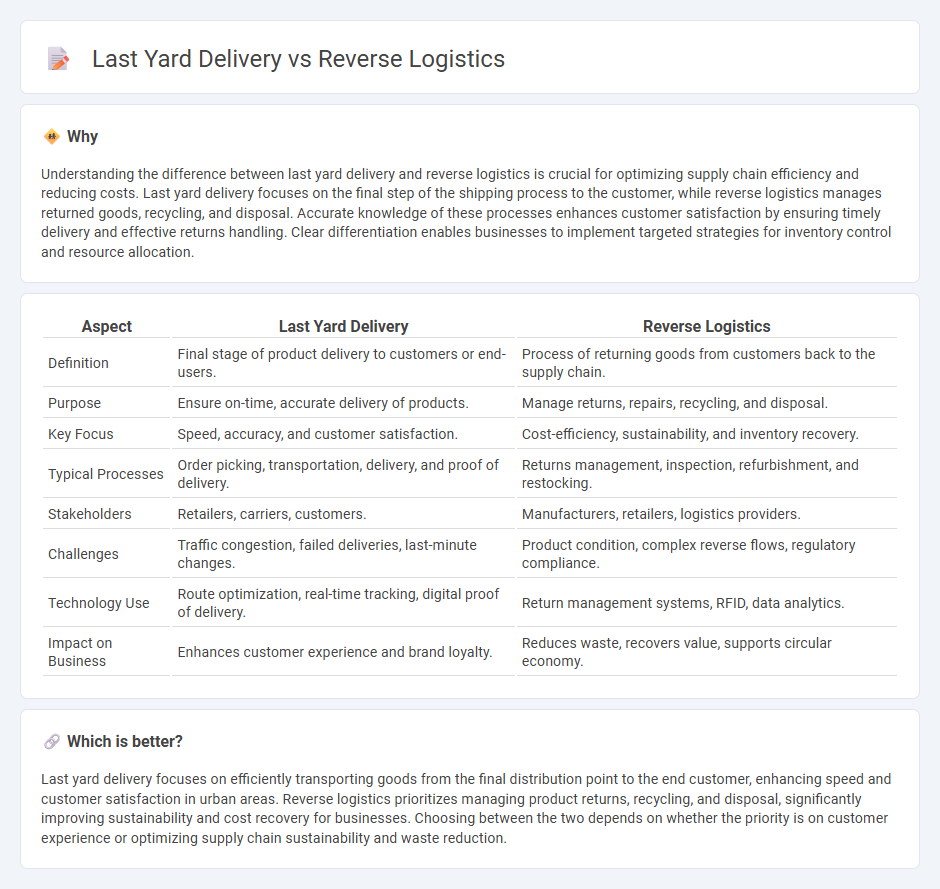

Understanding the difference between last yard delivery and reverse logistics is crucial for optimizing supply chain efficiency and reducing costs. Last yard delivery focuses on the final step of the shipping process to the customer, while reverse logistics manages returned goods, recycling, and disposal. Accurate knowledge of these processes enhances customer satisfaction by ensuring timely delivery and effective returns handling. Clear differentiation enables businesses to implement targeted strategies for inventory control and resource allocation.

Comparison Table

| Aspect | Last Yard Delivery | Reverse Logistics |

|---|---|---|

| Definition | Final stage of product delivery to customers or end-users. | Process of returning goods from customers back to the supply chain. |

| Purpose | Ensure on-time, accurate delivery of products. | Manage returns, repairs, recycling, and disposal. |

| Key Focus | Speed, accuracy, and customer satisfaction. | Cost-efficiency, sustainability, and inventory recovery. |

| Typical Processes | Order picking, transportation, delivery, and proof of delivery. | Returns management, inspection, refurbishment, and restocking. |

| Stakeholders | Retailers, carriers, customers. | Manufacturers, retailers, logistics providers. |

| Challenges | Traffic congestion, failed deliveries, last-minute changes. | Product condition, complex reverse flows, regulatory compliance. |

| Technology Use | Route optimization, real-time tracking, digital proof of delivery. | Return management systems, RFID, data analytics. |

| Impact on Business | Enhances customer experience and brand loyalty. | Reduces waste, recovers value, supports circular economy. |

Which is better?

Last yard delivery focuses on efficiently transporting goods from the final distribution point to the end customer, enhancing speed and customer satisfaction in urban areas. Reverse logistics prioritizes managing product returns, recycling, and disposal, significantly improving sustainability and cost recovery for businesses. Choosing between the two depends on whether the priority is on customer experience or optimizing supply chain sustainability and waste reduction.

Connection

Last yard delivery and reverse logistics are interconnected through their focus on the final stages of the supply chain, ensuring efficient product movement between distribution centers and end consumers. Optimizing last yard delivery minimizes delivery time and costs, while effective reverse logistics manages returns, repairs, and recycling, enhancing sustainability and customer satisfaction. Integrated solutions combining these processes improve overall logistics efficiency, reduce environmental impact, and streamline order fulfillment and returns management.

Key Terms

Reverse Logistics:

Reverse logistics involves the process of managing product returns, recycling, refurbishment, and disposal, aiming to recover value and reduce waste. It plays a critical role in sustainability efforts by minimizing environmental impact and optimizing supply chain efficiency. Explore our detailed insights to understand how reverse logistics accelerates business growth and enhances customer satisfaction.

Returns Management

Reverse logistics in returns management involves the efficient handling of returned products to minimize losses and optimize inventory recovery, focusing on transportation, inspection, and restocking processes. Last yard delivery emphasizes the final stage of product return, ensuring timely pickup and seamless reintegration into the supply chain while enhancing customer experience. Explore the key differences and strategies in returns management by diving deeper into reverse logistics and last yard delivery practices.

Recycling

Reverse logistics emphasizes the efficient return and recycling of products to minimize waste and promote sustainability, involving processes such as collection, sorting, and refurbishment. Last yard delivery focuses on the final stage of transporting goods to the consumer, which can integrate recycling initiatives by enabling convenient product returns and deposit pickups. Explore how combining reverse logistics and last yard delivery optimizes recycling efforts and reduces environmental impact.

Source and External Links

What is Reverse Logistics? - Reverse logistics is the process of moving goods from their final destination back to the manufacturer or distributor for return, repair, remanufacture, recycling, or disposal, aiming to recapture value and support a leaner, more efficient supply chain.

A Guide to Reverse Logistics: How It Works, Types and ... - Reverse logistics involves managing the return of goods from customers to sellers or manufacturers, including returns processing, refurbishment, recycling, and remanufacturing, with industry-specific variations like container reuse in beverages or material recycling in construction.

Reverse logistics - Reverse logistics encompasses all operations related to the upstream movement of products for value recovery or proper disposal, including remanufacturing and refurbishing, and is growing due to environmental concerns and green supply chain practices.

dowidth.com

dowidth.com