Cold chain visibility enhances real-time tracking of temperature-sensitive goods, ensuring product integrity and compliance throughout the supply chain. Cold chain risk management focuses on identifying, assessing, and mitigating potential disruptions such as equipment failure or transportation delays that could compromise product quality. Explore how integrating visibility with risk management optimizes cold chain performance and reduces financial losses.

Why it is important

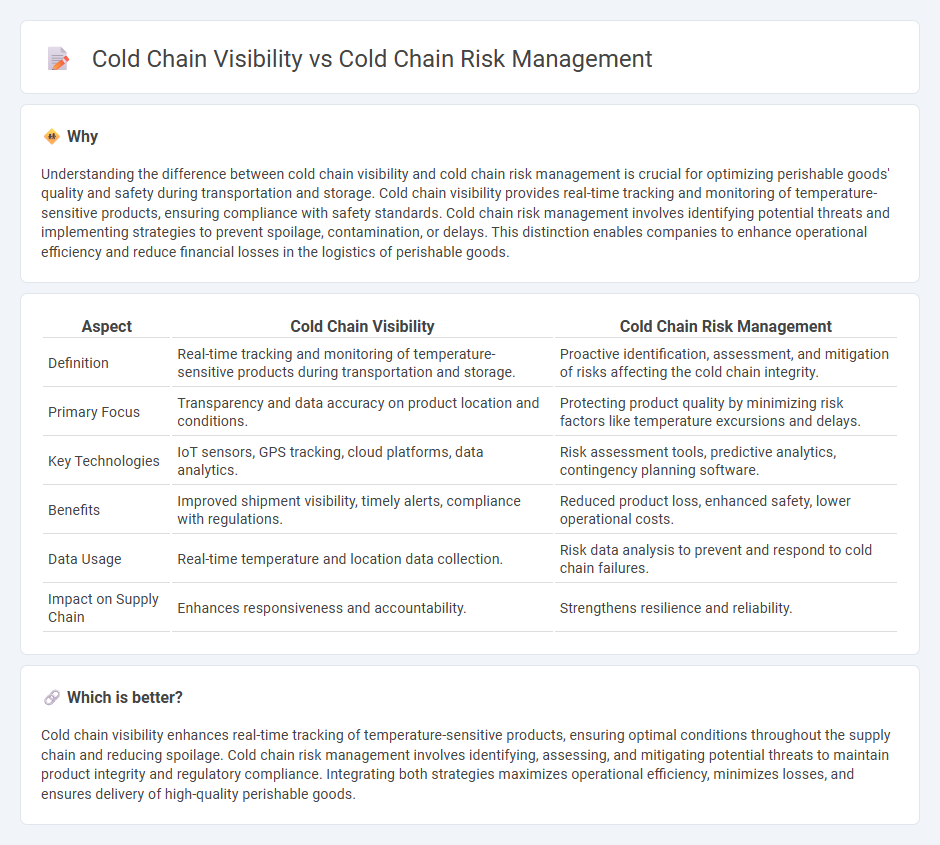

Understanding the difference between cold chain visibility and cold chain risk management is crucial for optimizing perishable goods' quality and safety during transportation and storage. Cold chain visibility provides real-time tracking and monitoring of temperature-sensitive products, ensuring compliance with safety standards. Cold chain risk management involves identifying potential threats and implementing strategies to prevent spoilage, contamination, or delays. This distinction enables companies to enhance operational efficiency and reduce financial losses in the logistics of perishable goods.

Comparison Table

| Aspect | Cold Chain Visibility | Cold Chain Risk Management |

|---|---|---|

| Definition | Real-time tracking and monitoring of temperature-sensitive products during transportation and storage. | Proactive identification, assessment, and mitigation of risks affecting the cold chain integrity. |

| Primary Focus | Transparency and data accuracy on product location and conditions. | Protecting product quality by minimizing risk factors like temperature excursions and delays. |

| Key Technologies | IoT sensors, GPS tracking, cloud platforms, data analytics. | Risk assessment tools, predictive analytics, contingency planning software. |

| Benefits | Improved shipment visibility, timely alerts, compliance with regulations. | Reduced product loss, enhanced safety, lower operational costs. |

| Data Usage | Real-time temperature and location data collection. | Risk data analysis to prevent and respond to cold chain failures. |

| Impact on Supply Chain | Enhances responsiveness and accountability. | Strengthens resilience and reliability. |

Which is better?

Cold chain visibility enhances real-time tracking of temperature-sensitive products, ensuring optimal conditions throughout the supply chain and reducing spoilage. Cold chain risk management involves identifying, assessing, and mitigating potential threats to maintain product integrity and regulatory compliance. Integrating both strategies maximizes operational efficiency, minimizes losses, and ensures delivery of high-quality perishable goods.

Connection

Cold chain visibility enables real-time tracking of temperature-sensitive shipments, ensuring compliance with safety standards and reducing spoilage risks. Effective cold chain risk management relies on this visibility to identify, assess, and mitigate potential disruptions such as equipment failures or temperature deviations. Integrating advanced IoT sensors and data analytics enhances predictive capabilities, safeguarding product integrity throughout the logistics process.

Key Terms

**Cold Chain Risk Management:**

Cold Chain Risk Management prioritizes identifying, assessing, and mitigating hazards throughout the temperature-controlled supply chain, including temperature excursions, equipment failures, and human errors that compromise product integrity. This strategic approach integrates real-time monitoring, predictive analytics, and contingency planning to ensure compliance with regulatory standards like FDA and WHO guidelines. Explore more about advanced risk management techniques to safeguard cold chain efficiency and product safety.

Hazard Analysis

Cold chain risk management prioritizes identifying, assessing, and mitigating hazards such as temperature deviations, contamination, and equipment failure to ensure product safety and quality throughout the supply chain. Cold chain visibility leverages real-time tracking and monitoring technologies to provide actionable insights into temperature fluctuations and handling conditions, enabling proactive responses to prevent hazards. Explore detailed strategies and tools for integrating hazard analysis in cold chain operations to optimize safety and compliance.

Contingency Planning

Cold chain risk management emphasizes identifying, assessing, and mitigating potential disruptions to maintain product integrity in temperature-sensitive supply chains. Cold chain visibility provides real-time tracking and monitoring of environmental conditions, enabling proactive responses to temperature excursions or delays. Explore detailed strategies to enhance contingency planning and strengthen cold chain resilience for optimized operational performance.

Source and External Links

The Ultimate Guide To Cold Chain Risk Management - Cold chain risk management involves planning, monitoring, and transporting temperature-sensitive products with strategies focusing on contingency planning, robust SOPs, digital transformation, and leveraging technology for proactive risk management.

PAXAFE's Guide to Proactive Risk Mitigation in Cold Chain Logistics - Effective cold chain risk mitigation requires a proactive approach including real-time location and condition monitoring, predictive analytics, regulatory compliance, training, and collaboration to prevent costly disruptions.

Ensuring Seamless Cold Chain Transportation: 5 Key Strategies For Effective Risk Mitigation - Managing cold chain risks is critical to avoid financial losses, protect product integrity, maintain regulatory compliance, and build consumer trust through ongoing training and optimized processes.

dowidth.com

dowidth.com