Middle mile optimization focuses on improving transportation efficiency between warehouses and distribution centers, significantly reducing transit times and operational costs. Warehouse location selection involves strategically positioning storage facilities to balance proximity to suppliers and customers, enhancing overall supply chain responsiveness. Explore deeper insights into how these strategies impact logistics performance and cost management.

Why it is important

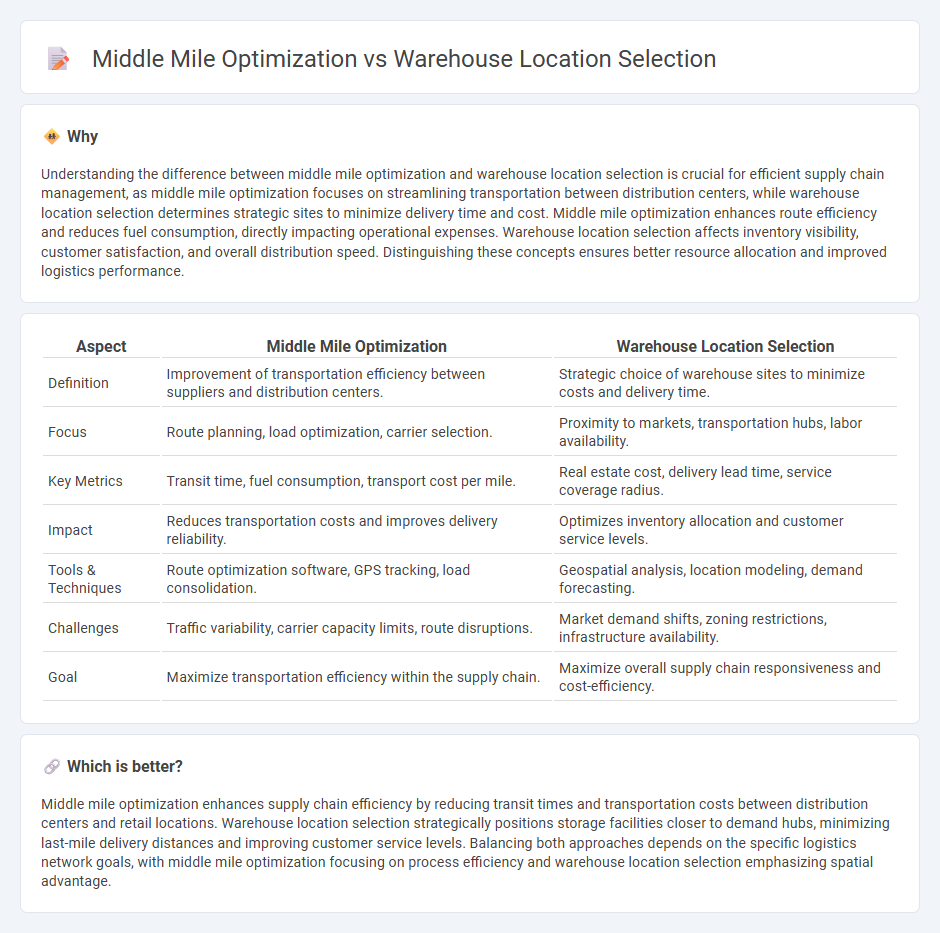

Understanding the difference between middle mile optimization and warehouse location selection is crucial for efficient supply chain management, as middle mile optimization focuses on streamlining transportation between distribution centers, while warehouse location selection determines strategic sites to minimize delivery time and cost. Middle mile optimization enhances route efficiency and reduces fuel consumption, directly impacting operational expenses. Warehouse location selection affects inventory visibility, customer satisfaction, and overall distribution speed. Distinguishing these concepts ensures better resource allocation and improved logistics performance.

Comparison Table

| Aspect | Middle Mile Optimization | Warehouse Location Selection |

|---|---|---|

| Definition | Improvement of transportation efficiency between suppliers and distribution centers. | Strategic choice of warehouse sites to minimize costs and delivery time. |

| Focus | Route planning, load optimization, carrier selection. | Proximity to markets, transportation hubs, labor availability. |

| Key Metrics | Transit time, fuel consumption, transport cost per mile. | Real estate cost, delivery lead time, service coverage radius. |

| Impact | Reduces transportation costs and improves delivery reliability. | Optimizes inventory allocation and customer service levels. |

| Tools & Techniques | Route optimization software, GPS tracking, load consolidation. | Geospatial analysis, location modeling, demand forecasting. |

| Challenges | Traffic variability, carrier capacity limits, route disruptions. | Market demand shifts, zoning restrictions, infrastructure availability. |

| Goal | Maximize transportation efficiency within the supply chain. | Maximize overall supply chain responsiveness and cost-efficiency. |

Which is better?

Middle mile optimization enhances supply chain efficiency by reducing transit times and transportation costs between distribution centers and retail locations. Warehouse location selection strategically positions storage facilities closer to demand hubs, minimizing last-mile delivery distances and improving customer service levels. Balancing both approaches depends on the specific logistics network goals, with middle mile optimization focusing on process efficiency and warehouse location selection emphasizing spatial advantage.

Connection

Middle mile optimization directly influences warehouse location selection by determining optimal transit routes and delivery times, which reduce transportation costs and improve supply chain efficiency. Strategic warehouse placement closer to key distribution hubs minimizes middle mile distances, accelerating inventory flow and enhancing customer service levels. Data-driven analysis of middle mile dynamics supports selecting warehouse sites that balance proximity to suppliers and demand centers, maximizing overall logistics performance.

Key Terms

**Warehouse Location Selection:**

Warehouse location selection directly impacts supply chain efficiency by strategically positioning facilities close to key markets and transportation hubs, reducing delivery times and transportation costs. Factors such as proximity to suppliers, labor availability, infrastructure quality, and regional demand patterns drive optimal site selection. Explore how precise warehouse placement enhances operational performance and cost-effectiveness.

Proximity to demand centers

Warehouse location selection emphasizes proximity to demand centers to reduce last-mile delivery costs and improve customer satisfaction by minimizing transit times. Middle mile optimization focuses on streamlining transportation routes between warehouses and regional hubs to enhance efficiency and reduce operational expenses. Explore more insights on balancing warehouse placement with middle mile strategies to maximize supply chain performance.

Transportation infrastructure

Warehouse location selection heavily impacts transportation infrastructure by determining proximity to key highways, ports, and railways, which reduces transit time and fuel costs in supply chains. Middle mile optimization enhances route efficiency between warehouses and distribution centers, leveraging transportation networks to minimize delays and improve delivery reliability. Explore detailed strategies to maximize transportation infrastructure benefits in your supply chain operations.

Source and External Links

Five Important Factors When Considering Warehouse Site Selection - Key factors in warehouse location selection include proximity to suppliers and customers, transportation access, labor availability, and real estate costs, all critically impacting delivery speed and supply chain efficiency.

Choosing a Warehouse Location: 7 Critical Criteria to Consider - Selecting a warehouse location demands analyzing transportation modes (airports, ports, rail), market proximity, environmental risks, and local infrastructure to reduce costs and optimize supply chain responsiveness.

Warehouse Location Strategy: Your Site Selection Checklist - Proximity to suppliers and customers is essential for timely deliveries and avoiding supply chain disruptions, along with considering specific transport options based on the goods handled, including pipelines for liquids and gases.

dowidth.com

dowidth.com