Supply chain control towers provide real-time visibility, predictive analytics, and proactive decision-making capabilities that enhance overall supply chain agility and responsiveness. Enterprise Resource Planning (ERP) systems focus on integrating core business processes such as inventory management, procurement, and order processing into a centralized platform for efficient resource planning. Explore the differences between supply chain control towers and ERP systems to optimize your logistics strategy.

Why it is important

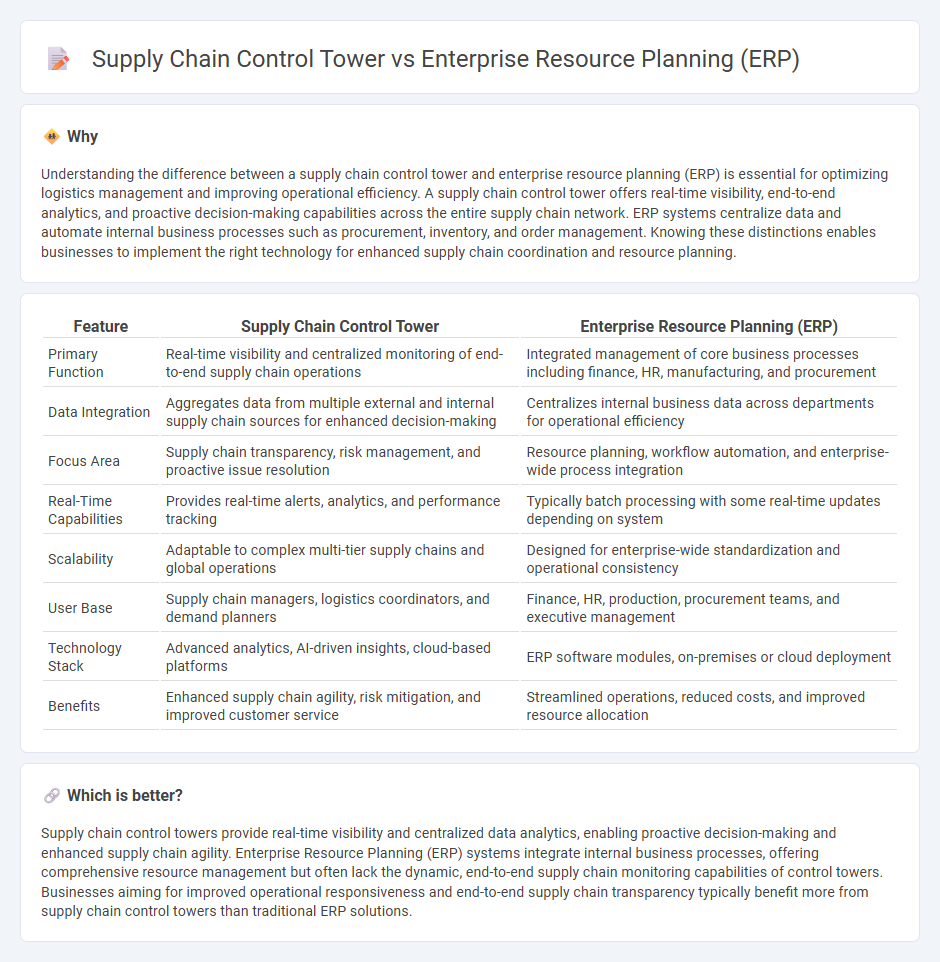

Understanding the difference between a supply chain control tower and enterprise resource planning (ERP) is essential for optimizing logistics management and improving operational efficiency. A supply chain control tower offers real-time visibility, end-to-end analytics, and proactive decision-making capabilities across the entire supply chain network. ERP systems centralize data and automate internal business processes such as procurement, inventory, and order management. Knowing these distinctions enables businesses to implement the right technology for enhanced supply chain coordination and resource planning.

Comparison Table

| Feature | Supply Chain Control Tower | Enterprise Resource Planning (ERP) |

|---|---|---|

| Primary Function | Real-time visibility and centralized monitoring of end-to-end supply chain operations | Integrated management of core business processes including finance, HR, manufacturing, and procurement |

| Data Integration | Aggregates data from multiple external and internal supply chain sources for enhanced decision-making | Centralizes internal business data across departments for operational efficiency |

| Focus Area | Supply chain transparency, risk management, and proactive issue resolution | Resource planning, workflow automation, and enterprise-wide process integration |

| Real-Time Capabilities | Provides real-time alerts, analytics, and performance tracking | Typically batch processing with some real-time updates depending on system |

| Scalability | Adaptable to complex multi-tier supply chains and global operations | Designed for enterprise-wide standardization and operational consistency |

| User Base | Supply chain managers, logistics coordinators, and demand planners | Finance, HR, production, procurement teams, and executive management |

| Technology Stack | Advanced analytics, AI-driven insights, cloud-based platforms | ERP software modules, on-premises or cloud deployment |

| Benefits | Enhanced supply chain agility, risk mitigation, and improved customer service | Streamlined operations, reduced costs, and improved resource allocation |

Which is better?

Supply chain control towers provide real-time visibility and centralized data analytics, enabling proactive decision-making and enhanced supply chain agility. Enterprise Resource Planning (ERP) systems integrate internal business processes, offering comprehensive resource management but often lack the dynamic, end-to-end supply chain monitoring capabilities of control towers. Businesses aiming for improved operational responsiveness and end-to-end supply chain transparency typically benefit more from supply chain control towers than traditional ERP solutions.

Connection

Supply chain control towers and enterprise resource planning (ERP) systems are interconnected through real-time data integration that enhances visibility and decision-making across the supply chain. Control towers aggregate information from ERP modules such as inventory management, procurement, and production planning to provide centralized monitoring and predictive analytics. This synchronization drives operational efficiency by enabling proactive responses to disruptions and optimizing resource allocation throughout the supply chain network.

Key Terms

Integration

Enterprise Resource Planning (ERP) systems centralize core business processes, including finance, HR, and inventory management, offering integrated data across departments for streamlined operations. Supply Chain Control Towers provide real-time visibility, advanced analytics, and proactive decision-making capabilities focused specifically on supply chain activities, offering enhanced responsiveness to disruptions. Explore how combining ERP's comprehensive integration with Control Tower's dynamic oversight can transform operational efficiency.

Visibility

Enterprise Resource Planning (ERP) systems integrate core business processes to provide data consistency, while Supply Chain Control Towers offer real-time end-to-end visibility across the entire supply chain network. ERP emphasizes internal departmental visibility and transactional data management, whereas Control Towers specialize in dynamic monitoring, predictive analytics, and exception management for external supplier and logistics operations. Explore deeper insights on how each solution enhances supply chain visibility and operational efficiency.

Real-time Analytics

Enterprise Resource Planning (ERP) systems integrate core business processes, offering centralized data but often lack the granular, real-time analytics crucial for dynamic supply chain decisions. Supply Chain Control Towers specialize in real-time visibility and predictive analytics across the entire supply chain network, enabling faster response to disruptions and optimized inventory management. Explore how leveraging real-time analytics in control towers can transform supply chain efficiency beyond traditional ERP capabilities.

Source and External Links

Enterprise resource planning - Wikipedia - Enterprise Resource Planning (ERP) is an integrated management system of core business processes, typically via software, that enables real-time data sharing across departments, tracking resources such as cash, materials, and production capacity to optimize business objectives and efficiency.

What is Enterprise Resource Planning (ERP)? - IBM - ERP is business management software that streamlines and automates an organization's processes--including finance, HR, manufacturing, and supply chain--using connected modules sharing a common database to eliminate data silos and promote operational efficiency.

What is ERP? A Comprehensive Guide - NetSuite - ERP software automates business functions and centralizes data from various departments to provide insights, improve workflows, reduce errors, and support growth with flexible deployment options like cloud or on-premises.

dowidth.com

dowidth.com