Collaborative logistics enhances supply chain efficiency by integrating multiple stakeholders to share resources, information, and transportation, reducing costs and improving delivery speed. Outbound logistics focuses specifically on the process of moving finished products from warehouses to customers or distribution centers, ensuring timely and accurate delivery. Explore the advantages and applications of both to optimize your logistics strategy.

Why it is important

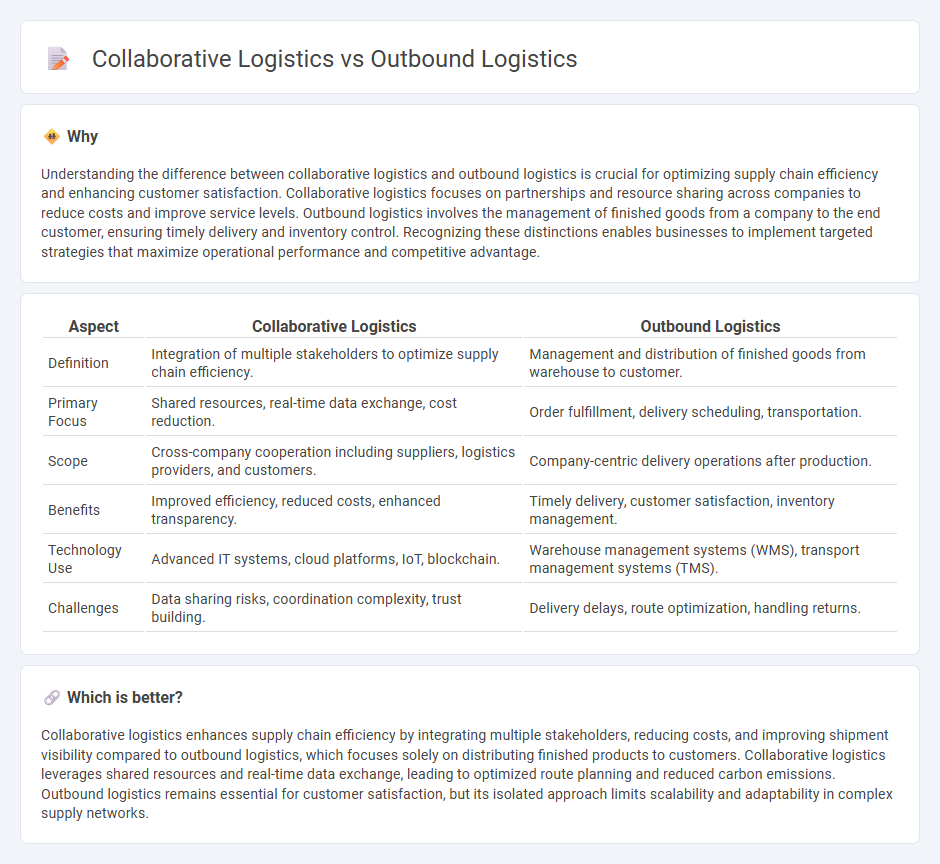

Understanding the difference between collaborative logistics and outbound logistics is crucial for optimizing supply chain efficiency and enhancing customer satisfaction. Collaborative logistics focuses on partnerships and resource sharing across companies to reduce costs and improve service levels. Outbound logistics involves the management of finished goods from a company to the end customer, ensuring timely delivery and inventory control. Recognizing these distinctions enables businesses to implement targeted strategies that maximize operational performance and competitive advantage.

Comparison Table

| Aspect | Collaborative Logistics | Outbound Logistics |

|---|---|---|

| Definition | Integration of multiple stakeholders to optimize supply chain efficiency. | Management and distribution of finished goods from warehouse to customer. |

| Primary Focus | Shared resources, real-time data exchange, cost reduction. | Order fulfillment, delivery scheduling, transportation. |

| Scope | Cross-company cooperation including suppliers, logistics providers, and customers. | Company-centric delivery operations after production. |

| Benefits | Improved efficiency, reduced costs, enhanced transparency. | Timely delivery, customer satisfaction, inventory management. |

| Technology Use | Advanced IT systems, cloud platforms, IoT, blockchain. | Warehouse management systems (WMS), transport management systems (TMS). |

| Challenges | Data sharing risks, coordination complexity, trust building. | Delivery delays, route optimization, handling returns. |

Which is better?

Collaborative logistics enhances supply chain efficiency by integrating multiple stakeholders, reducing costs, and improving shipment visibility compared to outbound logistics, which focuses solely on distributing finished products to customers. Collaborative logistics leverages shared resources and real-time data exchange, leading to optimized route planning and reduced carbon emissions. Outbound logistics remains essential for customer satisfaction, but its isolated approach limits scalability and adaptability in complex supply networks.

Connection

Collaborative logistics streamlines outbound logistics by enhancing coordination among suppliers, distributors, and transporters to optimize delivery routes and reduce costs. Effective sharing of inventory and transportation resources in outbound logistics improves delivery speed and customer satisfaction. Integrating collaborative logistics technologies like real-time tracking systems boosts transparency and efficiency throughout the outbound supply chain.

Key Terms

Distribution

Outbound logistics centers on the efficient movement of finished goods from the warehouse to the customer, emphasizing timely distribution, inventory management, and transportation optimization. Collaborative logistics integrates multiple stakeholders, including suppliers, manufacturers, and distributors, to enhance distribution efficiency through shared resources and synchronized planning. Discover how leveraging collaborative logistics can transform your distribution strategy for improved performance.

Partnerships

Outbound logistics centers on managing the distribution of finished goods from the company to the customer, emphasizing efficient transportation, warehousing, and order fulfillment processes. Collaborative logistics involves strategic partnerships between multiple stakeholders, such as suppliers, manufacturers, and distributors, to optimize supply chain performance through shared resources, information exchange, and joint planning. Discover how leveraging collaborative logistics partnerships can transform your supply chain efficiency and reduce operational costs.

Coordination

Outbound logistics emphasizes the efficient movement and distribution of finished products from warehouses to customers, optimizing transportation routes and delivery schedules. Collaborative logistics prioritizes coordination among multiple stakeholders, such as suppliers, manufacturers, and carriers, to share resources, reduce costs, and enhance supply chain responsiveness. Explore the key differences and benefits of coordination in outbound versus collaborative logistics to improve your logistical strategies.

Source and External Links

Outbound Logistics Distribution Guide | Fulfill.com Glossary - Outbound logistics encompasses all steps from order processing, warehousing, packaging, transportation, to delivery, ensuring products reach customers on time and in good condition, which is critical to customer satisfaction.

Inbound Logistics: Processes, Comparisons, and Optimization vs Outbound Logistics - Outbound logistics involves transporting products from a company to its customers and can be optimized by diversifying distribution channels, optimizing transportation routes, using demand forecasting, and maintaining customer communication.

What Is Outbound Logistics? Core Components and Processes - Outbound logistics is the system by which businesses store, pack, and transport finished goods to customers, focusing on efficient storage, inventory management, and reliable transportation to fulfill orders effectively.

dowidth.com

dowidth.com