Pick and pack involves selecting individual items from inventory and packaging them for shipment, optimizing order accuracy and reducing delivery times. Transloading transfers goods between different transportation modes, enhancing supply chain flexibility and cost efficiency. Explore further to understand which logistics solution best fits your operational needs.

Why it is important

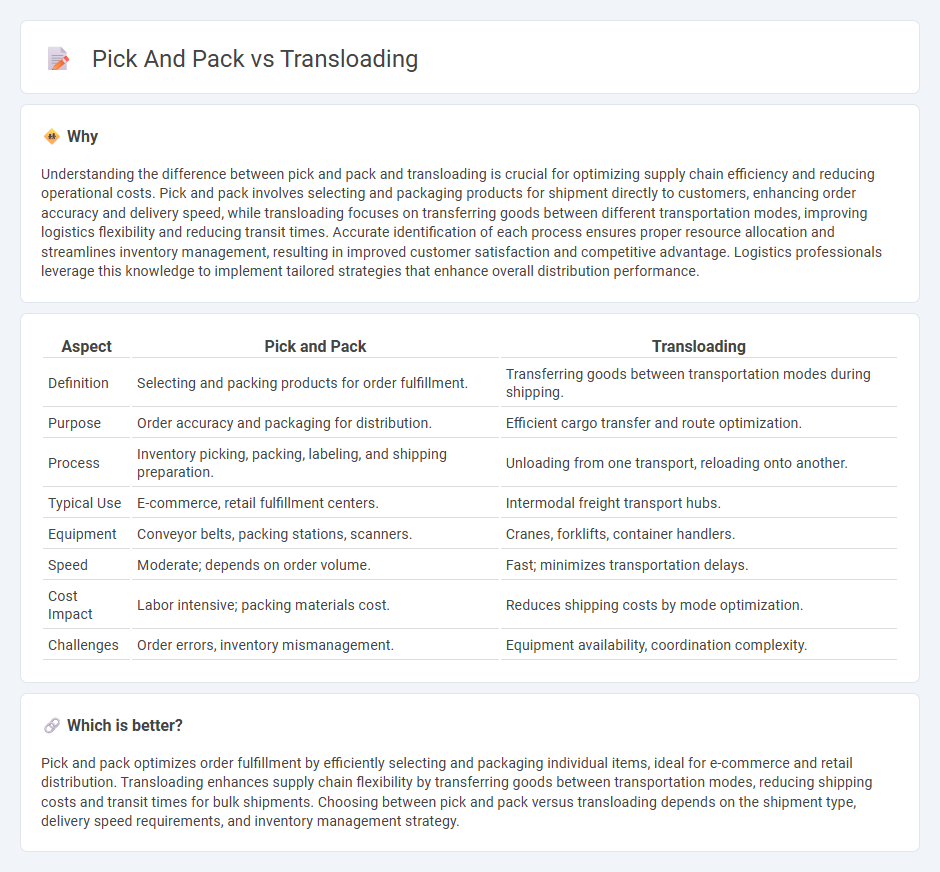

Understanding the difference between pick and pack and transloading is crucial for optimizing supply chain efficiency and reducing operational costs. Pick and pack involves selecting and packaging products for shipment directly to customers, enhancing order accuracy and delivery speed, while transloading focuses on transferring goods between different transportation modes, improving logistics flexibility and reducing transit times. Accurate identification of each process ensures proper resource allocation and streamlines inventory management, resulting in improved customer satisfaction and competitive advantage. Logistics professionals leverage this knowledge to implement tailored strategies that enhance overall distribution performance.

Comparison Table

| Aspect | Pick and Pack | Transloading |

|---|---|---|

| Definition | Selecting and packing products for order fulfillment. | Transferring goods between transportation modes during shipping. |

| Purpose | Order accuracy and packaging for distribution. | Efficient cargo transfer and route optimization. |

| Process | Inventory picking, packing, labeling, and shipping preparation. | Unloading from one transport, reloading onto another. |

| Typical Use | E-commerce, retail fulfillment centers. | Intermodal freight transport hubs. |

| Equipment | Conveyor belts, packing stations, scanners. | Cranes, forklifts, container handlers. |

| Speed | Moderate; depends on order volume. | Fast; minimizes transportation delays. |

| Cost Impact | Labor intensive; packing materials cost. | Reduces shipping costs by mode optimization. |

| Challenges | Order errors, inventory mismanagement. | Equipment availability, coordination complexity. |

Which is better?

Pick and pack optimizes order fulfillment by efficiently selecting and packaging individual items, ideal for e-commerce and retail distribution. Transloading enhances supply chain flexibility by transferring goods between transportation modes, reducing shipping costs and transit times for bulk shipments. Choosing between pick and pack versus transloading depends on the shipment type, delivery speed requirements, and inventory management strategy.

Connection

Pick and pack and transloading are interconnected logistics processes that streamline supply chain efficiency by ensuring accurate order fulfillment and efficient cargo transfer. Pick and pack involves selecting items from inventory and packaging them for shipment, while transloading facilitates the transfer of goods between different transportation modes to optimize delivery routes. Combining these operations reduces handling time, minimizes damage risk, and accelerates distribution in multi-modal logistics networks.

Key Terms

Mode Transfer

Mode transfer in transloading involves transferring goods between different transportation modes, such as from rail to truck, optimizing logistics efficiency and reducing shipping times. Pick and pack centers focus on sorting, packing, and preparing orders but typically do not involve changing transportation modes during the process. Explore how mode transfer impacts supply chain strategies and logistics solutions to optimize your operations.

Order Fulfillment

Transloading involves transferring goods from one mode of transport to another, optimizing supply chain efficiency and reducing transit time in order fulfillment processes. Pick and pack focuses on selecting individual items from inventory and packaging them for shipment, enhancing accuracy and speed in customer order preparation. Explore further to understand which method best suits your order fulfillment strategy.

Cross-Docking

Cross-docking streamlines logistics by unloading goods from inbound trucks directly to outbound trucks without long-term storage, enhancing efficiency compared to traditional pick and pack methods that involve order consolidation and packaging. Transloading focuses on transferring shipments between different transport modes or vehicles, while pick and pack entails selecting items from inventory to fulfill specific orders. Explore deeper insights into cross-docking benefits and applications to optimize supply chain operations.

Source and External Links

Transloading - Wikipedia - Transloading is the process of transferring a shipment from one mode of transportation to another, commonly used when multiple transport types are involved or at railroad break-of-gauge points, with facilities designed to minimize handling and damage risk.

Transloading: Meaning, Benefits, and Challenges - Inbound Logistics - Transloading transfers goods between different transportation modes during shipping to improve efficiency, overcome logistic challenges, and reduce costs, often involving third-party logistics providers.

Transloading in Logistics: Everything You Need to Know - Maersk - Transloading is the movement of goods between transport modes at specialized facilities using equipment like forklifts and cranes, including processes like unloading, sorting, consolidation, reloading, and documentation for onward shipment.

dowidth.com

dowidth.com