Freight visibility enhances supply chain efficiency by providing real-time tracking of shipments, ensuring timely deliveries and reducing transit risks. Warehouse management focuses on optimizing storage, inventory control, and order fulfillment within facilities to streamline operations and reduce costs. Explore how integrating freight visibility with warehouse management can elevate overall logistics performance.

Why it is important

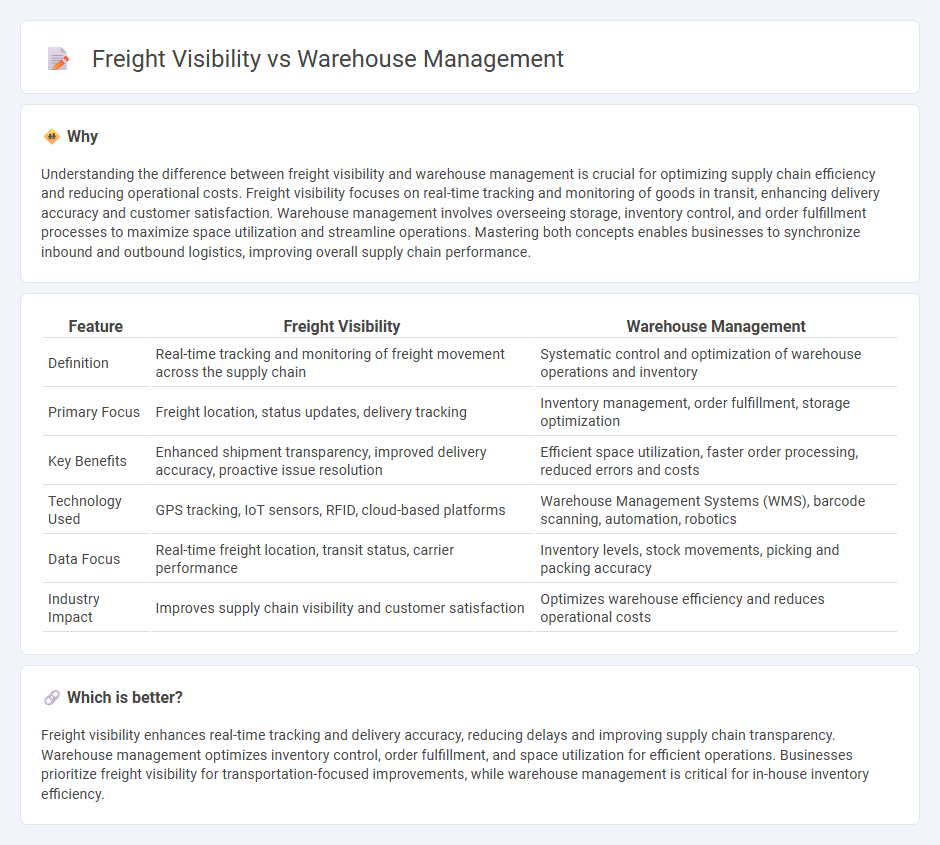

Understanding the difference between freight visibility and warehouse management is crucial for optimizing supply chain efficiency and reducing operational costs. Freight visibility focuses on real-time tracking and monitoring of goods in transit, enhancing delivery accuracy and customer satisfaction. Warehouse management involves overseeing storage, inventory control, and order fulfillment processes to maximize space utilization and streamline operations. Mastering both concepts enables businesses to synchronize inbound and outbound logistics, improving overall supply chain performance.

Comparison Table

| Feature | Freight Visibility | Warehouse Management |

|---|---|---|

| Definition | Real-time tracking and monitoring of freight movement across the supply chain | Systematic control and optimization of warehouse operations and inventory |

| Primary Focus | Freight location, status updates, delivery tracking | Inventory management, order fulfillment, storage optimization |

| Key Benefits | Enhanced shipment transparency, improved delivery accuracy, proactive issue resolution | Efficient space utilization, faster order processing, reduced errors and costs |

| Technology Used | GPS tracking, IoT sensors, RFID, cloud-based platforms | Warehouse Management Systems (WMS), barcode scanning, automation, robotics |

| Data Focus | Real-time freight location, transit status, carrier performance | Inventory levels, stock movements, picking and packing accuracy |

| Industry Impact | Improves supply chain visibility and customer satisfaction | Optimizes warehouse efficiency and reduces operational costs |

Which is better?

Freight visibility enhances real-time tracking and delivery accuracy, reducing delays and improving supply chain transparency. Warehouse management optimizes inventory control, order fulfillment, and space utilization for efficient operations. Businesses prioritize freight visibility for transportation-focused improvements, while warehouse management is critical for in-house inventory efficiency.

Connection

Freight visibility enhances warehouse management by providing real-time tracking of shipments, enabling accurate inventory forecasting and timely resource allocation. Integration of freight data with warehouse systems streamlines operations, reduces delays, and improves order fulfillment accuracy. Effective synchronization between freight visibility and warehouse management increases supply chain transparency and optimizes overall logistics efficiency.

Key Terms

**Warehouse Management:**

Warehouse management optimizes inventory control, space utilization, and order fulfillment processes to enhance operational efficiency and reduce costs. It leverages technologies like WMS (Warehouse Management Systems) to monitor stock levels, track shipments, and streamline labor management. Explore how advanced warehouse management solutions can transform your supply chain performance.

Inventory Control

Warehouse management optimizes inventory control by tracking stock levels, locations, and movements within storage facilities using real-time data and automation technologies to reduce errors and improve order accuracy. Freight visibility enhances inventory control by providing end-to-end shipment tracking, enabling better demand forecasting and timely replenishment of stock across the supply chain. Discover how integrating warehouse management with freight visibility drives superior inventory control to meet customer expectations.

Slotting Optimization

Warehouse management leverages slotting optimization to enhance inventory placement, reducing picking time and increasing operational efficiency. Freight visibility, while centered on tracking shipments, benefits from optimized slotting by ensuring faster loading and unloading processes. Explore how integrating slotting optimization can transform both warehouse management and freight visibility for superior supply chain performance.

Source and External Links

What is Warehouse Management? Processes, Performance ... - Warehouse management involves daily oversight of warehouse operations focusing on maintaining optimal stock levels, efficient sales order processing, organizing material handling, processing transactions efficiently, and linking warehouse management with sales order processing and logistics for optimized picking, packing, and shipping.

What is Warehouse Management? Benefits, Processes & ... - Warehouse management includes six core processes: receiving, put-away, storage, picking, packing, and shipping, all crucial for efficient warehouse operation and performance optimization.

Warehouse Management: A Complete Guide (2025) - Effective warehouse management optimizes inbound and outbound processes, leverages real-time performance analytics, and maximizes labor productivity to achieve fast, precise, and error-free operations.

dowidth.com

dowidth.com