Shared warehousing optimizes storage by consolidating inventory from multiple companies in a single location, reducing costs and improving space utilization. Cross-docking streamlines supply chains by transferring products directly from inbound to outbound transportation, minimizing storage time and accelerating delivery. Explore these logistics strategies to enhance operational efficiency and meet evolving distribution demands.

Why it is important

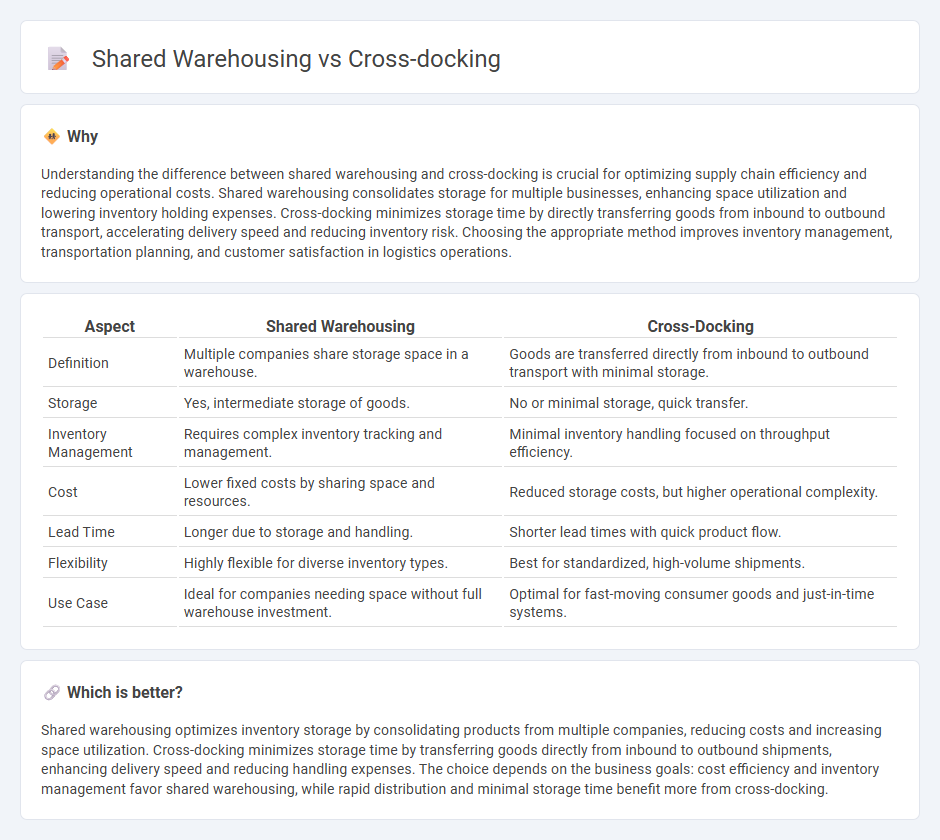

Understanding the difference between shared warehousing and cross-docking is crucial for optimizing supply chain efficiency and reducing operational costs. Shared warehousing consolidates storage for multiple businesses, enhancing space utilization and lowering inventory holding expenses. Cross-docking minimizes storage time by directly transferring goods from inbound to outbound transport, accelerating delivery speed and reducing inventory risk. Choosing the appropriate method improves inventory management, transportation planning, and customer satisfaction in logistics operations.

Comparison Table

| Aspect | Shared Warehousing | Cross-Docking |

|---|---|---|

| Definition | Multiple companies share storage space in a warehouse. | Goods are transferred directly from inbound to outbound transport with minimal storage. |

| Storage | Yes, intermediate storage of goods. | No or minimal storage, quick transfer. |

| Inventory Management | Requires complex inventory tracking and management. | Minimal inventory handling focused on throughput efficiency. |

| Cost | Lower fixed costs by sharing space and resources. | Reduced storage costs, but higher operational complexity. |

| Lead Time | Longer due to storage and handling. | Shorter lead times with quick product flow. |

| Flexibility | Highly flexible for diverse inventory types. | Best for standardized, high-volume shipments. |

| Use Case | Ideal for companies needing space without full warehouse investment. | Optimal for fast-moving consumer goods and just-in-time systems. |

Which is better?

Shared warehousing optimizes inventory storage by consolidating products from multiple companies, reducing costs and increasing space utilization. Cross-docking minimizes storage time by transferring goods directly from inbound to outbound shipments, enhancing delivery speed and reducing handling expenses. The choice depends on the business goals: cost efficiency and inventory management favor shared warehousing, while rapid distribution and minimal storage time benefit more from cross-docking.

Connection

Shared warehousing maximizes storage efficiency by allowing multiple businesses to store goods in a common facility, reducing costs and optimizing space utilization. Cross-docking complements this setup by facilitating the rapid transfer of products from inbound to outbound transportation with minimal storage time, enhancing supply chain speed and reducing inventory holding costs. The integration of shared warehousing and cross-docking creates a synergistic logistics model that improves distribution efficiency and lowers operational expenses.

Key Terms

Inventory Turnover

Cross-docking minimizes storage time by directly transferring goods from inbound to outbound shipments, significantly accelerating inventory turnover rates. Shared warehousing pools resources among multiple businesses, optimizing space utilization but often resulting in longer inventory holding periods. Explore detailed comparisons to understand how each method impacts your inventory turnover and supply chain efficiency.

Consolidation

Cross-docking minimizes storage time by directly transferring goods from inbound to outbound transportation, optimizing consolidation by reducing inventory handling and improving shipment efficiency. Shared warehousing enables multiple companies to consolidate shipments within a common facility, lowering costs through shared space and resources while accommodating varying inventory needs. Discover how choosing between cross-docking and shared warehousing can enhance your supply chain consolidation strategy.

Distribution Efficiency

Cross-docking minimizes storage time by directly transferring products from inbound to outbound transportation, reducing handling costs and accelerating delivery speeds. Shared warehousing pools resources across multiple businesses, optimizing storage utilization and lowering overall inventory carrying expenses. Explore the advantages of each strategy to enhance your distribution efficiency and supply chain performance.

Source and External Links

Cross Docking: Definition, History, and Process - Cross docking is a shipping method that transfers goods directly from inbound to outbound transportation modes with minimal storage, using methods like continuous cross docking, consolidation, and de-consolidation to improve efficiency and reduce costs.

What Is Cross-Docking? Definition, Types & Advantages - Cross-docking is a supply chain strategy that speeds delivery by unloading goods from inbound vehicles and loading them directly onto outbound vehicles at logistics facilities, minimizing or eliminating storage time, and benefiting various industries by optimizing inventory and reducing costs.

Understanding cross-docking: A comprehensive guide - Cross-docking involves minimal storage time during goods transfer and can be categorized by timing of sorting (pre-distribution or post-distribution), specific processes (continuous, consolidation, deconsolidation), and industry-specific applications such as retail, manufacturing, and e-commerce.

dowidth.com

dowidth.com