Containerization streamlines cargo transport by using standardized containers that simplify loading, unloading, and transfer across ships, trucks, and trains, enhancing efficiency and security in supply chains. Cross-docking minimizes storage time by directly transferring goods from inbound to outbound transportation with little or no warehousing, reducing handling and accelerating delivery schedules. Explore the differences and benefits of containerization and cross-docking to optimize your logistics operations.

Why it is important

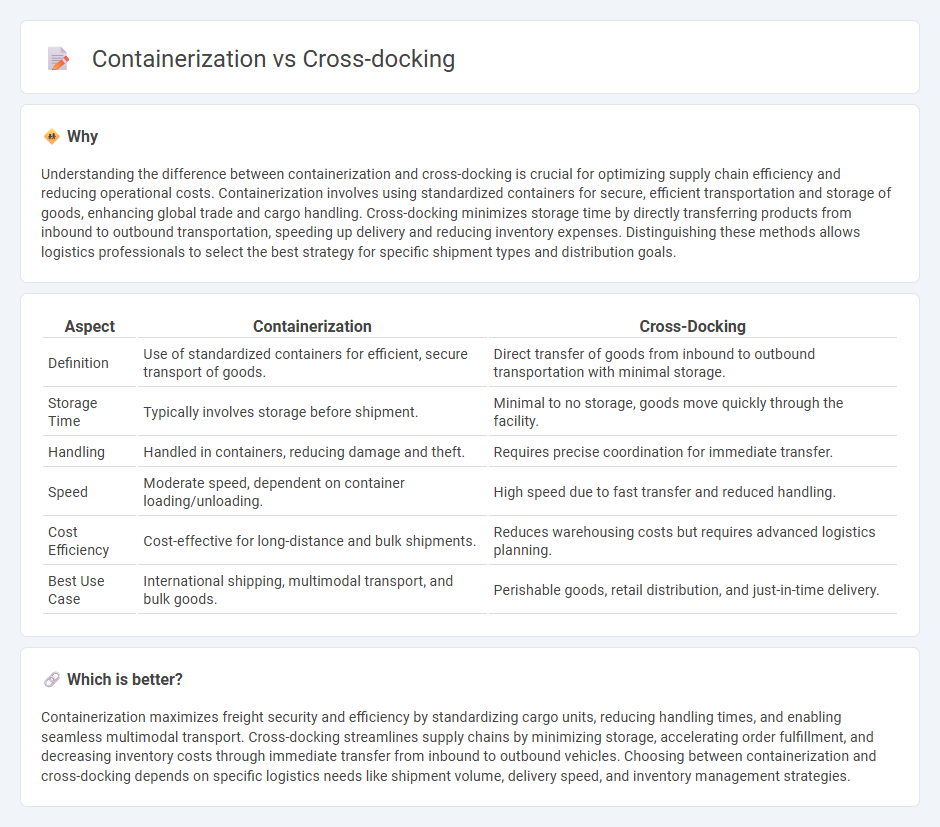

Understanding the difference between containerization and cross-docking is crucial for optimizing supply chain efficiency and reducing operational costs. Containerization involves using standardized containers for secure, efficient transportation and storage of goods, enhancing global trade and cargo handling. Cross-docking minimizes storage time by directly transferring products from inbound to outbound transportation, speeding up delivery and reducing inventory expenses. Distinguishing these methods allows logistics professionals to select the best strategy for specific shipment types and distribution goals.

Comparison Table

| Aspect | Containerization | Cross-Docking |

|---|---|---|

| Definition | Use of standardized containers for efficient, secure transport of goods. | Direct transfer of goods from inbound to outbound transportation with minimal storage. |

| Storage Time | Typically involves storage before shipment. | Minimal to no storage, goods move quickly through the facility. |

| Handling | Handled in containers, reducing damage and theft. | Requires precise coordination for immediate transfer. |

| Speed | Moderate speed, dependent on container loading/unloading. | High speed due to fast transfer and reduced handling. |

| Cost Efficiency | Cost-effective for long-distance and bulk shipments. | Reduces warehousing costs but requires advanced logistics planning. |

| Best Use Case | International shipping, multimodal transport, and bulk goods. | Perishable goods, retail distribution, and just-in-time delivery. |

Which is better?

Containerization maximizes freight security and efficiency by standardizing cargo units, reducing handling times, and enabling seamless multimodal transport. Cross-docking streamlines supply chains by minimizing storage, accelerating order fulfillment, and decreasing inventory costs through immediate transfer from inbound to outbound vehicles. Choosing between containerization and cross-docking depends on specific logistics needs like shipment volume, delivery speed, and inventory management strategies.

Connection

Containerization streamlines the handling and transportation of goods by using standardized containers that facilitate efficient loading, unloading, and transfer processes in logistics hubs. Cross-docking leverages these containers to minimize storage time by directly transferring goods from inbound to outbound transportation, reducing inventory holding costs. This integration enhances supply chain speed and reduces handling errors, optimizing overall logistics efficiency.

Key Terms

Transshipment

Cross-docking streamlines transshipment by directly transferring goods from inbound to outbound transportation with minimal storage time, enhancing efficiency and reducing handling costs. Containerization facilitates transshipment by standardizing cargo units, simplifying loading, unloading, and transportation across multiple shipping modes. Explore more to understand how these logistics strategies optimize transshipment operations in global supply chains.

Consolidation

Cross-docking streamlines consolidation by rapidly transferring goods from inbound to outbound transportation with minimal storage, reducing inventory holding costs and accelerating order fulfillment. Containerization enhances consolidation through standardized containers that group shipments efficiently, optimizing space utilization and simplifying handling across multimodal transport. Explore deeper insights into how these methods transform supply chain consolidation for improved efficiency.

Handling time

Cross-docking minimizes handling time by directly transferring goods from inbound to outbound transportation with little to no storage, significantly reducing warehouse dwell time. Containerization improves handling efficiency by consolidating cargo into standardized containers, facilitating quicker loading and unloading, but still involves some storage and transfer time. Explore how these logistics strategies impact operational speed and cost-effectiveness in supply chain management.

Source and External Links

Cross Docking: Definition, History, and Process - Inbound Logistics - Cross docking is a shipping method transferring goods directly from one transportation mode to another with minimal storage, including continuous, consolidation, and de-consolidation methods for efficient handling and distribution.

What Is Cross-Docking? Definition, Types & Advantages - NetSuite - Cross-docking is a supply chain technique that speeds delivery and reduces costs by transferring goods directly from inbound to outbound vehicles at logistics facilities, minimizing storage time.

Understanding cross-docking: A comprehensive guide - Maersk - Cross-docking is a logistics process transferring products from suppliers to customers with minimal storage, with types including pre-distribution, post-distribution, continuous, consolidation, and deconsolidation tailored for retail, manufacturing, and e-commerce sectors.

dowidth.com

dowidth.com