Milk run delivery involves a single vehicle collecting shipments from multiple suppliers on a predetermined route, optimizing consolidation and reducing transportation costs. Just-in-time delivery focuses on precise scheduling and rapid transport to minimize inventory levels and ensure components arrive exactly when needed in the production process. Discover how these logistics strategies can streamline operations and improve supply chain efficiency.

Why it is important

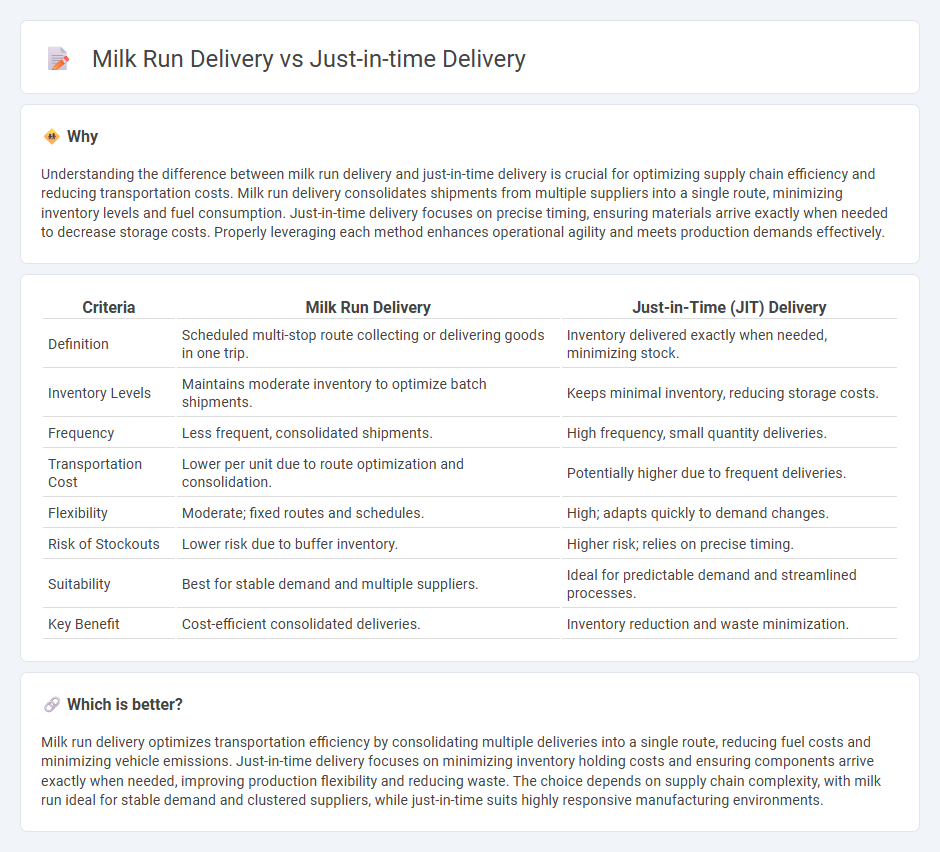

Understanding the difference between milk run delivery and just-in-time delivery is crucial for optimizing supply chain efficiency and reducing transportation costs. Milk run delivery consolidates shipments from multiple suppliers into a single route, minimizing inventory levels and fuel consumption. Just-in-time delivery focuses on precise timing, ensuring materials arrive exactly when needed to decrease storage costs. Properly leveraging each method enhances operational agility and meets production demands effectively.

Comparison Table

| Criteria | Milk Run Delivery | Just-in-Time (JIT) Delivery |

|---|---|---|

| Definition | Scheduled multi-stop route collecting or delivering goods in one trip. | Inventory delivered exactly when needed, minimizing stock. |

| Inventory Levels | Maintains moderate inventory to optimize batch shipments. | Keeps minimal inventory, reducing storage costs. |

| Frequency | Less frequent, consolidated shipments. | High frequency, small quantity deliveries. |

| Transportation Cost | Lower per unit due to route optimization and consolidation. | Potentially higher due to frequent deliveries. |

| Flexibility | Moderate; fixed routes and schedules. | High; adapts quickly to demand changes. |

| Risk of Stockouts | Lower risk due to buffer inventory. | Higher risk; relies on precise timing. |

| Suitability | Best for stable demand and multiple suppliers. | Ideal for predictable demand and streamlined processes. |

| Key Benefit | Cost-efficient consolidated deliveries. | Inventory reduction and waste minimization. |

Which is better?

Milk run delivery optimizes transportation efficiency by consolidating multiple deliveries into a single route, reducing fuel costs and minimizing vehicle emissions. Just-in-time delivery focuses on minimizing inventory holding costs and ensuring components arrive exactly when needed, improving production flexibility and reducing waste. The choice depends on supply chain complexity, with milk run ideal for stable demand and clustered suppliers, while just-in-time suits highly responsive manufacturing environments.

Connection

Milk run delivery optimizes logistics by consolidating multiple shipments into a single route, reducing transportation costs and inventory levels. Just-in-time (JIT) delivery relies on this efficiency to ensure materials arrive precisely when needed, minimizing storage and waste. Together, they enhance supply chain responsiveness and cost-effectiveness in inventory management.

Key Terms

Inventory Minimization

Just-in-time delivery minimizes inventory by scheduling materials to arrive precisely when needed, reducing storage costs and waste. Milk run delivery consolidates shipments from multiple suppliers into a single route, optimizing inventory replenishment by balancing delivery frequency and load efficiency. Explore detailed strategies to further enhance inventory minimization through these delivery methods.

Route Optimization

Just-in-time delivery minimizes inventory costs by synchronizing shipments to arrive precisely when needed, requiring highly optimized routes to ensure timely arrivals and avoid production delays. Milk run delivery consolidates multiple deliveries into a single route, optimizing stops to reduce transportation costs and enhance load efficiency across suppliers or customers. Explore detailed strategies and software solutions to optimize routing for both delivery models and improve supply chain efficiency.

Supplier Coordination

Just-in-time delivery emphasizes precise timing and synchronization with suppliers to minimize inventory holding costs and reduce waste, requiring real-time communication and rapid response capabilities. Milk run delivery optimizes supplier coordination by consolidating shipments from multiple suppliers into a single route, enhancing load efficiency and reducing transportation costs while maintaining consistent supply flow. Explore in-depth strategies and best practices for supplier coordination in these delivery methods to optimize your supply chain performance.

Source and External Links

Just in Time Delivery: What is it, and How Does it Affect Supply ... - Just in time delivery is the process of producing goods with minimal inventory to satisfy demand immediately, ensuring products are delivered precisely when needed, commonly used in restaurants, grocery delivery, and retail industries for freshness and efficiency.

Just In Time (JIT) Delivery: The Ultimate Guide - Elite EXTRA - JIT delivery is a supply chain approach focusing on producing and delivering products on demand to reduce inventory costs, increase efficiency, flexibility, and improve quality by moving inventory only as needed.

What is JIT Delivery? - AGI Global Logistics - Just-In-Time delivery is a logistics strategy that minimizes inventory storage costs by ensuring goods arrive exactly when needed, based on actual demand rather than forecasts, utilizing principles like lean manufacturing and Kanban to eliminate waste and optimize processes.

dowidth.com

dowidth.com