Supply chain control towers provide real-time visibility and centralized monitoring of logistics, enabling rapid decision-making and enhanced coordination across multiple supply chain nodes. Production planning focuses on scheduling and optimizing manufacturing processes to meet demand efficiently while minimizing costs and downtime. Explore more to understand how integrating control towers and production planning can revolutionize supply chain management.

Why it is important

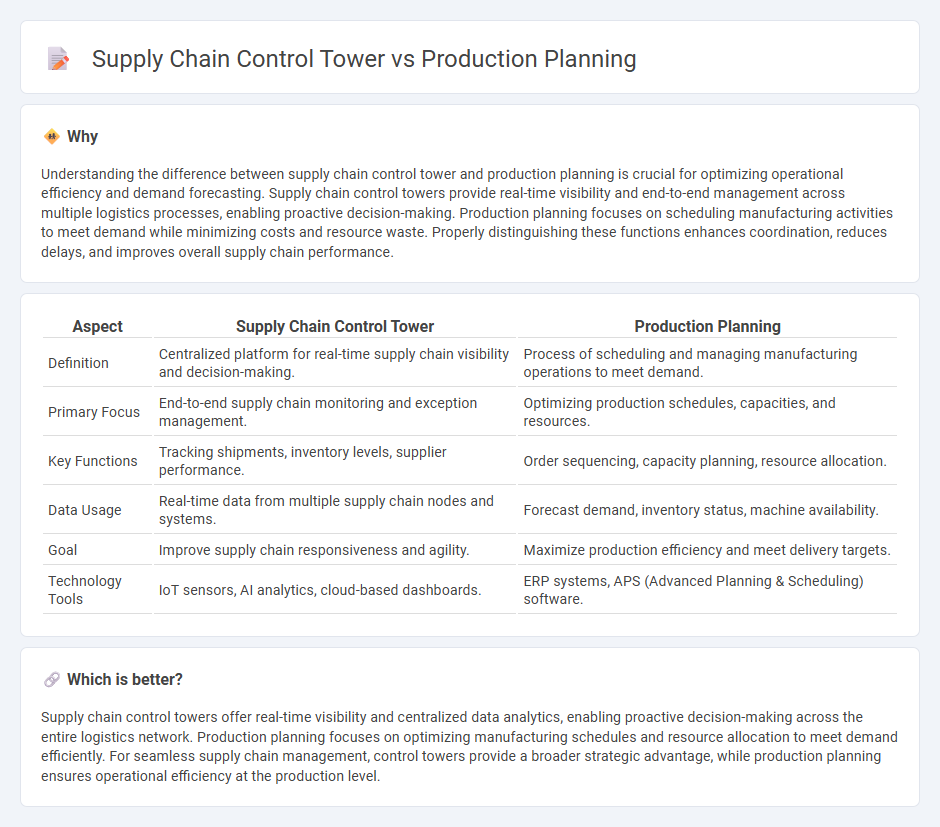

Understanding the difference between supply chain control tower and production planning is crucial for optimizing operational efficiency and demand forecasting. Supply chain control towers provide real-time visibility and end-to-end management across multiple logistics processes, enabling proactive decision-making. Production planning focuses on scheduling manufacturing activities to meet demand while minimizing costs and resource waste. Properly distinguishing these functions enhances coordination, reduces delays, and improves overall supply chain performance.

Comparison Table

| Aspect | Supply Chain Control Tower | Production Planning |

|---|---|---|

| Definition | Centralized platform for real-time supply chain visibility and decision-making. | Process of scheduling and managing manufacturing operations to meet demand. |

| Primary Focus | End-to-end supply chain monitoring and exception management. | Optimizing production schedules, capacities, and resources. |

| Key Functions | Tracking shipments, inventory levels, supplier performance. | Order sequencing, capacity planning, resource allocation. |

| Data Usage | Real-time data from multiple supply chain nodes and systems. | Forecast demand, inventory status, machine availability. |

| Goal | Improve supply chain responsiveness and agility. | Maximize production efficiency and meet delivery targets. |

| Technology Tools | IoT sensors, AI analytics, cloud-based dashboards. | ERP systems, APS (Advanced Planning & Scheduling) software. |

Which is better?

Supply chain control towers offer real-time visibility and centralized data analytics, enabling proactive decision-making across the entire logistics network. Production planning focuses on optimizing manufacturing schedules and resource allocation to meet demand efficiently. For seamless supply chain management, control towers provide a broader strategic advantage, while production planning ensures operational efficiency at the production level.

Connection

Supply chain control towers provide real-time visibility and data analytics that enhance production planning accuracy by identifying bottlenecks and forecasting demand fluctuations. Integration of control tower insights allows production planners to adjust schedules, optimize resource allocation, and reduce downtime. This connection ensures synchronized operations across the supply chain, improving responsiveness and overall efficiency.

Key Terms

Production Planning:

Production planning involves scheduling and managing resources to ensure efficient manufacturing processes and timely product delivery. It optimizes inventory levels, labor, and equipment usage to meet production targets and reduce downtime. Discover how production planning integrates with broader supply chain control tower functions to enhance operational efficiency.

Demand Forecasting

Production planning centers on demand forecasting by predicting future product requirements to optimize manufacturing schedules and inventory levels. Supply chain control towers utilize integrated, real-time data from multiple sources to provide end-to-end visibility, enhancing demand forecasting accuracy and responsiveness across the entire supply network. Explore how combining production planning with supply chain control tower insights can revolutionize your demand forecasting strategy.

Material Requirements Planning (MRP)

Material Requirements Planning (MRP) is a critical component of production planning, focusing on inventory control, scheduling, and procurement to ensure materials are available for manufacturing processes. Supply Chain Control Towers, on the other hand, provide a holistic, real-time view of the entire supply chain, integrating data from multiple sources to enhance visibility and decision-making across logistics, production, and inventory. Explore how syncing MRP with supply chain control towers can optimize production efficiency and responsiveness.

Source and External Links

Making a Production Plan (Example Included) - Project Manager - Production planning involves forecasting customer demand, assessing production capacity, and mapping out the production process steps to create an efficient manufacturing plan before production begins, using methods such as Delphi and moving average for demand planning.

Production planning - Wikipedia - Production planning is the process of allocating resources, scheduling work, and coordinating manufacturing activities to meet customer demands efficiently, incorporating capacity estimation, resource availability, and collaboration with sales and marketing departments.

What Are the Steps in Production Planning and Control? - OptiProERP - Key steps in production planning include planning (deciding what and how to produce), routing (defining the path of materials through production), and scheduling (setting operation completion times) to optimize resource use and meet deadlines.

dowidth.com

dowidth.com