Digital freight matching leverages advanced algorithms and real-time data to connect shippers and carriers efficiently, reducing empty miles and improving load matching accuracy compared to manual dispatching. Manual dispatching relies heavily on human judgment and phone or email communication, often resulting in longer wait times and higher operational costs. Explore the benefits of digital freight matching to optimize your logistics operations and increase profitability.

Why it is important

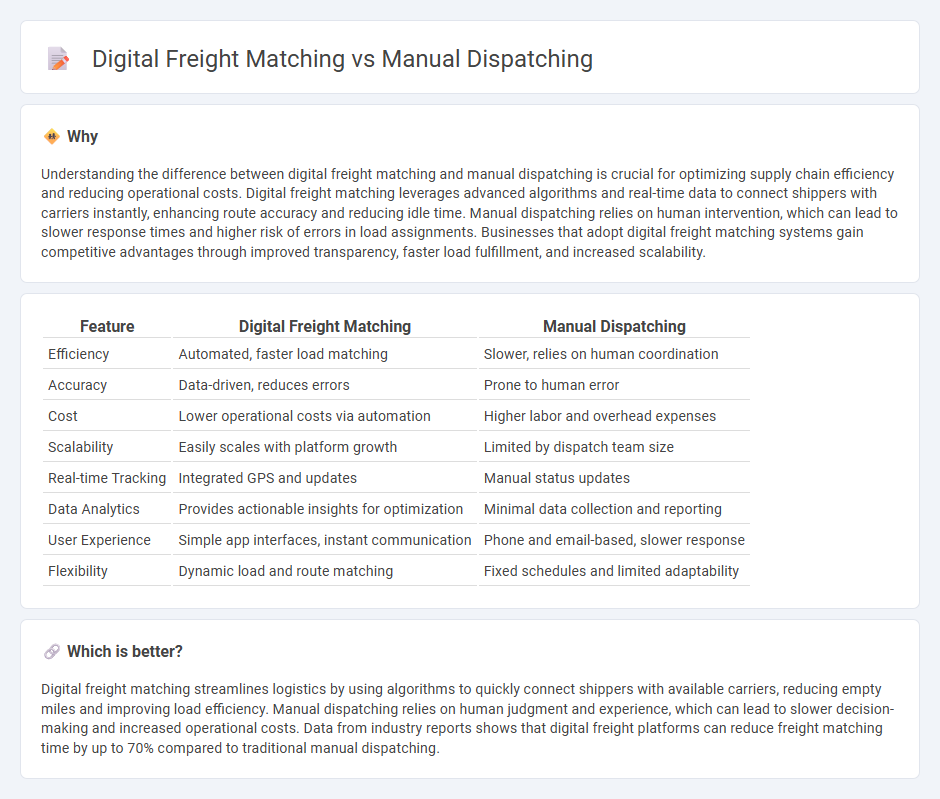

Understanding the difference between digital freight matching and manual dispatching is crucial for optimizing supply chain efficiency and reducing operational costs. Digital freight matching leverages advanced algorithms and real-time data to connect shippers with carriers instantly, enhancing route accuracy and reducing idle time. Manual dispatching relies on human intervention, which can lead to slower response times and higher risk of errors in load assignments. Businesses that adopt digital freight matching systems gain competitive advantages through improved transparency, faster load fulfillment, and increased scalability.

Comparison Table

| Feature | Digital Freight Matching | Manual Dispatching |

|---|---|---|

| Efficiency | Automated, faster load matching | Slower, relies on human coordination |

| Accuracy | Data-driven, reduces errors | Prone to human error |

| Cost | Lower operational costs via automation | Higher labor and overhead expenses |

| Scalability | Easily scales with platform growth | Limited by dispatch team size |

| Real-time Tracking | Integrated GPS and updates | Manual status updates |

| Data Analytics | Provides actionable insights for optimization | Minimal data collection and reporting |

| User Experience | Simple app interfaces, instant communication | Phone and email-based, slower response |

| Flexibility | Dynamic load and route matching | Fixed schedules and limited adaptability |

Which is better?

Digital freight matching streamlines logistics by using algorithms to quickly connect shippers with available carriers, reducing empty miles and improving load efficiency. Manual dispatching relies on human judgment and experience, which can lead to slower decision-making and increased operational costs. Data from industry reports shows that digital freight platforms can reduce freight matching time by up to 70% compared to traditional manual dispatching.

Connection

Digital freight matching platforms streamline the connection between shippers and carriers by using algorithms to optimize route efficiency and load capacity, reducing empty miles. Manual dispatching integrates with this technology by overseeing real-time adjustments, managing exceptions, and maintaining personalized communication with drivers and clients. Combining digital freight matching with manual dispatching enhances overall logistics performance, maximizing asset utilization and improving delivery reliability.

Key Terms

Load Assignment

Manual dispatching in load assignment relies heavily on human judgment, leading to slower decision-making and increased chances of errors, while digital freight matching leverages algorithms to swiftly pair loads with optimal carriers based on real-time data. Digital platforms enhance load assignment efficiency by analyzing factors such as carrier availability, location, and shipment specifications, reducing empty miles and boosting utilization rates. Explore the advantages of digital freight matching for streamlined load assignment and improved logistics performance.

Real-time Tracking

Manual dispatching relies heavily on phone calls and manual entry, often leading to delays and inaccuracies in real-time tracking data. Digital freight matching platforms integrate GPS technology and IoT devices to provide precise, instant updates on shipment locations and status, enhancing transparency and operational efficiency. Explore how real-time tracking through digital solutions can revolutionize freight management and improve delivery times.

Automation

Manual dispatching relies heavily on human intervention for booking and managing freight loads, often leading to slower response times and increased risk of errors. Digital freight matching automates these processes using algorithms and real-time data, significantly improving efficiency, accuracy, and load optimization. Explore how automation in freight management can transform your logistics operations and drive business growth.

Source and External Links

Manual vs. Automated Dispatch: Solving Common Scheduling Challenges - Manual dispatch is the traditional process of assigning tasks and vehicles using phone calls, spreadsheets, or handwritten notes, managed by a human dispatcher, but it faces challenges like human error, inefficiency, and lack of real-time insights as operations grow larger.

Manual vs. Automated Dispatching - SmartRoutes - Manual dispatching involves using pen and paper or spreadsheets for route planning and task assignments, favored for its simplicity and low cost, especially in small businesses, but it is prone to errors and delays due to manual route planning.

What is Dispatching? - Matrack Inc. - Manual dispatching uses traditional tools like logbooks, whiteboards, and phones, relying on dispatcher experience, which can lead to increased errors as business scale grows, contrasting with automated dispatching that uses software and real-time data for improved accuracy and scalability.

dowidth.com

dowidth.com