A supply chain control tower provides real-time visibility and centralized decision-making across multiple logistics functions, leveraging advanced analytics and AI to predict disruptions and optimize operations. In contrast, a control room typically focuses on monitoring and managing daily logistics activities within a specific area or operation. Explore the differences and benefits of these systems to enhance supply chain efficiency.

Why it is important

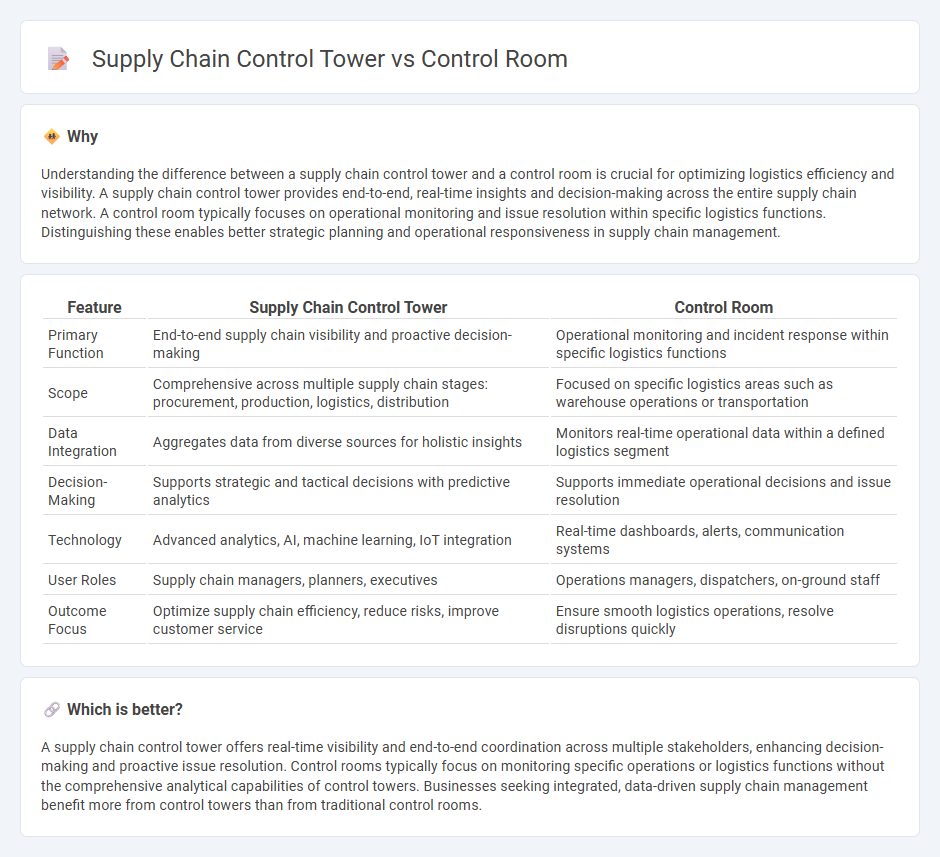

Understanding the difference between a supply chain control tower and a control room is crucial for optimizing logistics efficiency and visibility. A supply chain control tower provides end-to-end, real-time insights and decision-making across the entire supply chain network. A control room typically focuses on operational monitoring and issue resolution within specific logistics functions. Distinguishing these enables better strategic planning and operational responsiveness in supply chain management.

Comparison Table

| Feature | Supply Chain Control Tower | Control Room |

|---|---|---|

| Primary Function | End-to-end supply chain visibility and proactive decision-making | Operational monitoring and incident response within specific logistics functions |

| Scope | Comprehensive across multiple supply chain stages: procurement, production, logistics, distribution | Focused on specific logistics areas such as warehouse operations or transportation |

| Data Integration | Aggregates data from diverse sources for holistic insights | Monitors real-time operational data within a defined logistics segment |

| Decision-Making | Supports strategic and tactical decisions with predictive analytics | Supports immediate operational decisions and issue resolution |

| Technology | Advanced analytics, AI, machine learning, IoT integration | Real-time dashboards, alerts, communication systems |

| User Roles | Supply chain managers, planners, executives | Operations managers, dispatchers, on-ground staff |

| Outcome Focus | Optimize supply chain efficiency, reduce risks, improve customer service | Ensure smooth logistics operations, resolve disruptions quickly |

Which is better?

A supply chain control tower offers real-time visibility and end-to-end coordination across multiple stakeholders, enhancing decision-making and proactive issue resolution. Control rooms typically focus on monitoring specific operations or logistics functions without the comprehensive analytical capabilities of control towers. Businesses seeking integrated, data-driven supply chain management benefit more from control towers than from traditional control rooms.

Connection

The supply chain control tower functions as a centralized hub that provides end-to-end visibility and real-time data analytics across the entire logistics network. The control room acts as the operational space where supply chain managers monitor performance metrics, manage disruptions, and execute decision-making based on insights delivered by the control tower. This integration enables proactive management, improved efficiency, and enhanced responsiveness to dynamic supply chain challenges.

Key Terms

**Control Room:**

A Control Room centralizes real-time monitoring and management of operations within a specific facility or process, ensuring immediate response to disruptions and maintaining operational efficiency. It integrates various data streams such as equipment status, workforce activities, and environmental conditions for quick decision-making. Discover how Control Rooms revolutionize operational oversight and boost productivity in dynamic environments.

Real-time Monitoring

Control rooms are centralized hubs designed primarily for monitoring operational processes and responding to immediate issues, whereas supply chain control towers provide end-to-end visibility with advanced analytics for proactive supply chain management. Real-time monitoring in control towers leverages IoT devices, AI-driven insights, and predictive analytics to anticipate disruptions and optimize decision-making across the entire supply chain. Explore how integrating these technologies transforms your supply chain efficiency and risk management.

Incident Management

Control rooms primarily focus on real-time monitoring and immediate response to disruptions within specific operations, ensuring rapid incident resolution. Supply chain control towers provide end-to-end visibility, integrating data across multiple tiers to predict, detect, and manage incidents proactively throughout the entire supply chain network. Explore how combining control room agility with control tower oversight enhances incident management strategies.

Source and External Links

Control room - Wikipedia - A control room is a centralized space where a large facility or dispersed service is monitored and controlled, featuring ergonomic design elements and usually operating 24/7 with multiple operators for continuous vigilance.

ABB Control Room Solutions - ABB offers modular, ergonomic control room designs aimed to improve operator alertness, productivity, and safety in critical 24/7 operational environments.

Control Room (film) - Wikipedia - A 2004 documentary focusing on Al Jazeera's coverage of the 2003 Iraq invasion and its interaction with the US Central Command, exploring media perspectives during the conflict.

dowidth.com

dowidth.com