Drop shipping involves retailers selling products without holding inventory, directly shipping from suppliers to customers, reducing storage costs and minimizing risk. Consignment inventory allows retailers to stock products without upfront payment, gaining possession while suppliers retain ownership until sale, improving cash flow management. Explore the detailed differences between drop shipping and consignment inventory to optimize your logistics strategy.

Why it is important

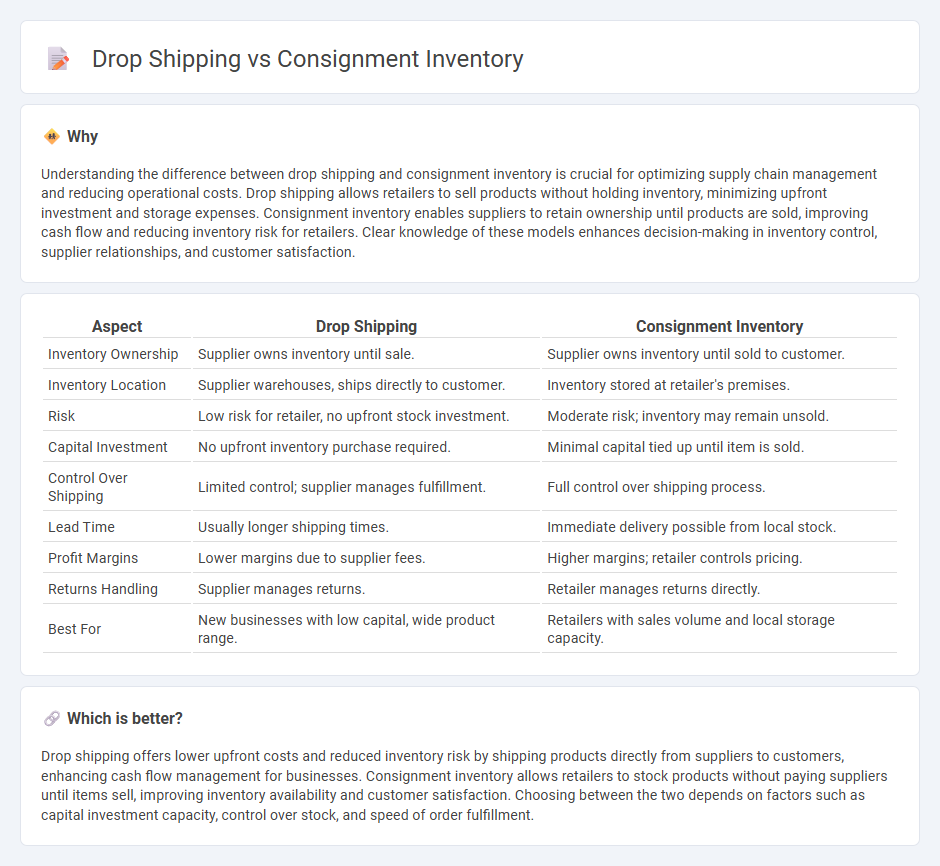

Understanding the difference between drop shipping and consignment inventory is crucial for optimizing supply chain management and reducing operational costs. Drop shipping allows retailers to sell products without holding inventory, minimizing upfront investment and storage expenses. Consignment inventory enables suppliers to retain ownership until products are sold, improving cash flow and reducing inventory risk for retailers. Clear knowledge of these models enhances decision-making in inventory control, supplier relationships, and customer satisfaction.

Comparison Table

| Aspect | Drop Shipping | Consignment Inventory |

|---|---|---|

| Inventory Ownership | Supplier owns inventory until sale. | Supplier owns inventory until sold to customer. |

| Inventory Location | Supplier warehouses, ships directly to customer. | Inventory stored at retailer's premises. |

| Risk | Low risk for retailer, no upfront stock investment. | Moderate risk; inventory may remain unsold. |

| Capital Investment | No upfront inventory purchase required. | Minimal capital tied up until item is sold. |

| Control Over Shipping | Limited control; supplier manages fulfillment. | Full control over shipping process. |

| Lead Time | Usually longer shipping times. | Immediate delivery possible from local stock. |

| Profit Margins | Lower margins due to supplier fees. | Higher margins; retailer controls pricing. |

| Returns Handling | Supplier manages returns. | Retailer manages returns directly. |

| Best For | New businesses with low capital, wide product range. | Retailers with sales volume and local storage capacity. |

Which is better?

Drop shipping offers lower upfront costs and reduced inventory risk by shipping products directly from suppliers to customers, enhancing cash flow management for businesses. Consignment inventory allows retailers to stock products without paying suppliers until items sell, improving inventory availability and customer satisfaction. Choosing between the two depends on factors such as capital investment capacity, control over stock, and speed of order fulfillment.

Connection

Drop shipping and consignment inventory both minimize upfront stock investment by shifting inventory holding responsibilities to suppliers or consignors, enhancing cash flow management in logistics operations. Each method streamlines order fulfillment by allowing retailers to sell products without physically storing them, reducing warehousing costs and risk of overstock. Integration of these models supports flexible supply chain strategies that improve inventory turnover and responsiveness to market demand.

Key Terms

Ownership

Consignment inventory allows suppliers to retain ownership of goods until they are sold by the retailer, minimizing the retailer's upfront investment and risk. In drop shipping, the retailer never physically handles or owns the inventory, as products are shipped directly from the supplier to the customer, streamlining operations but reducing control. Explore further to understand how ownership impacts supply chain efficiency and financial management.

Inventory Location

Consignment inventory is stored at the retailer's location but remains the supplier's property until sold, allowing closer control over stock availability and faster customer fulfillment. Drop shipping inventory resides at the supplier or manufacturer's warehouse, with the retailer forwarding orders directly to the supplier who ships to the customer, reducing the need for physical storage space. Explore more about how inventory location impacts logistics efficiency and cost management in these models.

Order Fulfillment

Consignment inventory allows retailers to store products on their shelves without upfront purchase costs, enabling immediate order fulfillment once a sale is made, while drop shipping relies on suppliers to ship products directly to customers, bypassing retailer inventory. With consignment, retailers control the packaging and shipping process, reducing delivery times and enhancing customer experience, whereas drop shipping often results in longer fulfillment cycles due to supplier handling. Explore the detailed differences in order fulfillment efficiency between consignment inventory and drop shipping to optimize your supply chain strategy.

Source and External Links

What Is Consignment Inventory and How Does It Work? - NetSuite - Consignment inventory is a supply chain model where a retailer sells products but the supplier retains ownership until a customer buys them, reducing the retailer's risk.

A Guide to Consignment Inventory Accounting: Pros, Cons, and Tips - In consignment arrangements, suppliers record goods sent on consignment as separate inventory, while retailers track the items but do not include them in their inventory until they are sold.

Consignment Inventory: Definition, Advantages, and Disadvantages - Consignment inventory refers to an agreement where the supplier delivers goods to a retailer, who pays only for what sells and returns unsold items, with the supplier maintaining ownership until sale.

dowidth.com

dowidth.com