Reverse logistics manages the return flow of goods from customers back to the manufacturer for returns, repairs, recycling, or disposal, focusing on sustainability and cost recovery. Inbound logistics involves the procurement, transportation, and storage of raw materials or components from suppliers to the production facility, emphasizing inventory management and supply chain efficiency. Discover more about how optimizing reverse and inbound logistics can enhance operational performance and reduce expenses.

Why it is important

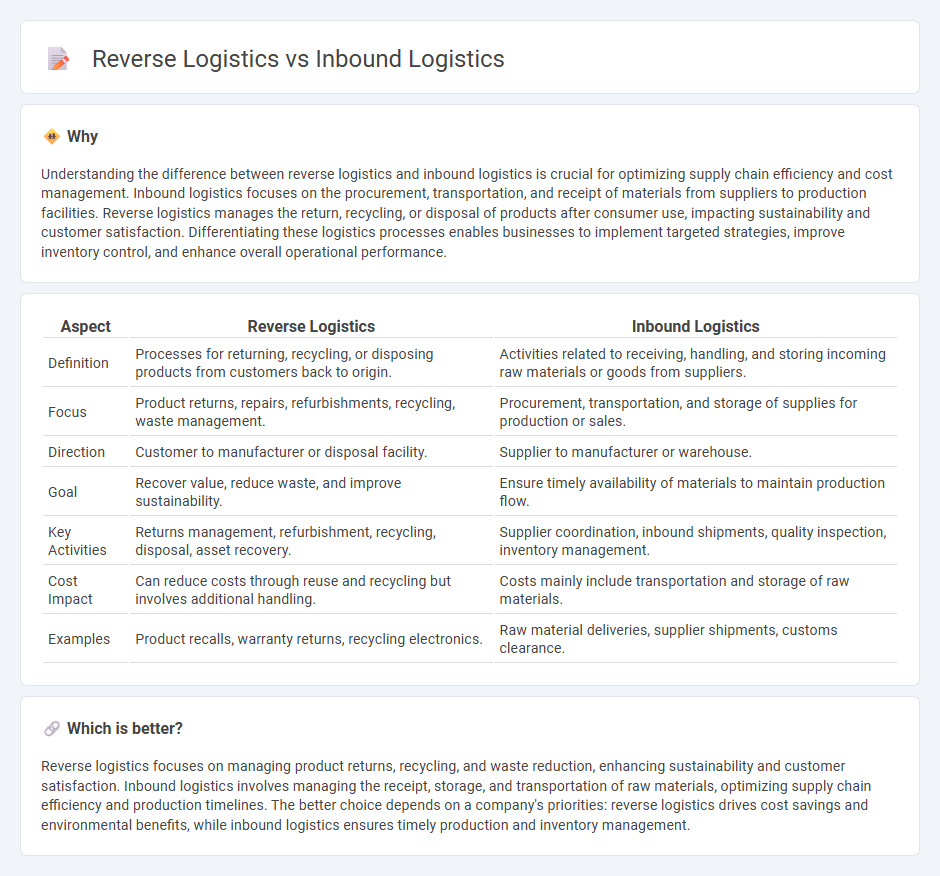

Understanding the difference between reverse logistics and inbound logistics is crucial for optimizing supply chain efficiency and cost management. Inbound logistics focuses on the procurement, transportation, and receipt of materials from suppliers to production facilities. Reverse logistics manages the return, recycling, or disposal of products after consumer use, impacting sustainability and customer satisfaction. Differentiating these logistics processes enables businesses to implement targeted strategies, improve inventory control, and enhance overall operational performance.

Comparison Table

| Aspect | Reverse Logistics | Inbound Logistics |

|---|---|---|

| Definition | Processes for returning, recycling, or disposing products from customers back to origin. | Activities related to receiving, handling, and storing incoming raw materials or goods from suppliers. |

| Focus | Product returns, repairs, refurbishments, recycling, waste management. | Procurement, transportation, and storage of supplies for production or sales. |

| Direction | Customer to manufacturer or disposal facility. | Supplier to manufacturer or warehouse. |

| Goal | Recover value, reduce waste, and improve sustainability. | Ensure timely availability of materials to maintain production flow. |

| Key Activities | Returns management, refurbishment, recycling, disposal, asset recovery. | Supplier coordination, inbound shipments, quality inspection, inventory management. |

| Cost Impact | Can reduce costs through reuse and recycling but involves additional handling. | Costs mainly include transportation and storage of raw materials. |

| Examples | Product recalls, warranty returns, recycling electronics. | Raw material deliveries, supplier shipments, customs clearance. |

Which is better?

Reverse logistics focuses on managing product returns, recycling, and waste reduction, enhancing sustainability and customer satisfaction. Inbound logistics involves managing the receipt, storage, and transportation of raw materials, optimizing supply chain efficiency and production timelines. The better choice depends on a company's priorities: reverse logistics drives cost savings and environmental benefits, while inbound logistics ensures timely production and inventory management.

Connection

Reverse logistics and inbound logistics are interconnected processes that focus on the movement of goods within a supply chain. Inbound logistics manages the flow of raw materials and products from suppliers to warehouses or production facilities, ensuring efficient supply chain inputs. Reverse logistics handles the return, recycling, and disposal of products, often feeding materials back into the inbound logistics cycle for reuse or resale, enhancing overall supply chain sustainability.

Key Terms

Supplier Management

Inbound logistics emphasizes efficient coordination of materials and information flow from suppliers to production, ensuring timely delivery and quality control to optimize supplier management. Reverse logistics involves managing the return, recycling, or disposal of products, requiring strong collaboration with suppliers for effective handling of returns, warranty claims, and sustainability goals. Explore how integrating inbound and reverse logistics strategies enhances overall supplier relationship management and operational efficiency.

Returns Processing

Inbound logistics emphasizes the efficient movement and storage of raw materials or products from suppliers to warehouses or production facilities, ensuring smooth supply chain operations. Reverse logistics specifically targets returns processing, handling customer returns, refurbishment, recycling, or disposal to maximize value recovery and sustainability. Explore comprehensive strategies for optimizing returns processing to enhance supply chain efficiency and customer satisfaction.

Inventory Flow

Inbound logistics manages the efficient movement and storage of raw materials and products from suppliers to warehouses or production facilities, optimizing inventory flow to ensure timely availability. Reverse logistics focuses on the return, recycling, or disposal of products from customers back to manufacturers or warehouses, emphasizing the recovery and resale of inventory to minimize waste. Explore detailed strategies for balancing inbound and reverse logistics to enhance overall supply chain performance.

Source and External Links

Guide to Inbound and Outbound Logistics: Processes, Differences ... - Inbound logistics covers the activities involved in bringing supplies and materials into a business, including sourcing, transportation, receiving, storage, and inventory management.

What Is inbound logistics? Inbound versus outbound logistics - FarEye - Inbound logistics refers to the transportation, storage, and delivery of goods and raw materials from suppliers to a business, aiming to streamline operations and reduce costs.

Inbound Logistics - ASCM - Inbound logistics is a critical supply chain function focused on coordinating and managing the flow of incoming goods into a company.

dowidth.com

dowidth.com