Micro-fulfillment centers leverage automation and proximity to customers to expedite order processing and reduce delivery times, making them ideal for e-commerce and urban retail. Cross-docking facilities focus on minimizing storage by directly transferring incoming shipments to outgoing transportation, enhancing supply chain efficiency and lowering inventory costs. Explore the distinct roles and operational benefits of these logistics strategies to optimize your distribution network.

Why it is important

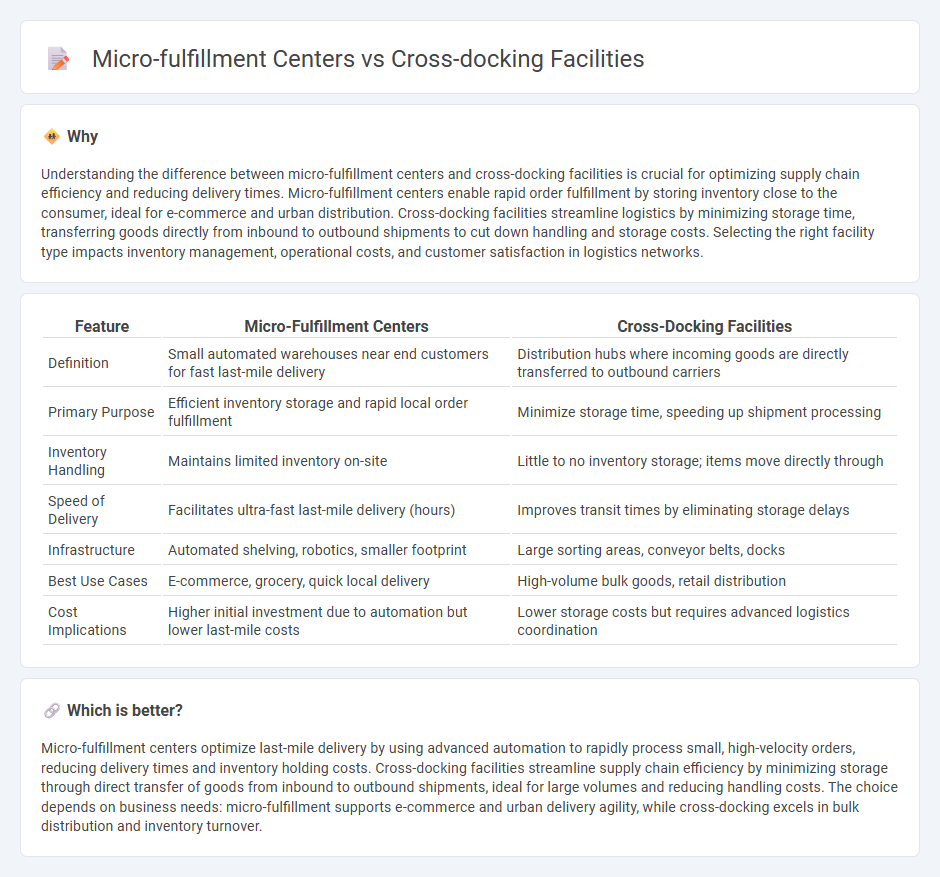

Understanding the difference between micro-fulfillment centers and cross-docking facilities is crucial for optimizing supply chain efficiency and reducing delivery times. Micro-fulfillment centers enable rapid order fulfillment by storing inventory close to the consumer, ideal for e-commerce and urban distribution. Cross-docking facilities streamline logistics by minimizing storage time, transferring goods directly from inbound to outbound shipments to cut down handling and storage costs. Selecting the right facility type impacts inventory management, operational costs, and customer satisfaction in logistics networks.

Comparison Table

| Feature | Micro-Fulfillment Centers | Cross-Docking Facilities |

|---|---|---|

| Definition | Small automated warehouses near end customers for fast last-mile delivery | Distribution hubs where incoming goods are directly transferred to outbound carriers |

| Primary Purpose | Efficient inventory storage and rapid local order fulfillment | Minimize storage time, speeding up shipment processing |

| Inventory Handling | Maintains limited inventory on-site | Little to no inventory storage; items move directly through |

| Speed of Delivery | Facilitates ultra-fast last-mile delivery (hours) | Improves transit times by eliminating storage delays |

| Infrastructure | Automated shelving, robotics, smaller footprint | Large sorting areas, conveyor belts, docks |

| Best Use Cases | E-commerce, grocery, quick local delivery | High-volume bulk goods, retail distribution |

| Cost Implications | Higher initial investment due to automation but lower last-mile costs | Lower storage costs but requires advanced logistics coordination |

Which is better?

Micro-fulfillment centers optimize last-mile delivery by using advanced automation to rapidly process small, high-velocity orders, reducing delivery times and inventory holding costs. Cross-docking facilities streamline supply chain efficiency by minimizing storage through direct transfer of goods from inbound to outbound shipments, ideal for large volumes and reducing handling costs. The choice depends on business needs: micro-fulfillment supports e-commerce and urban delivery agility, while cross-docking excels in bulk distribution and inventory turnover.

Connection

Micro-fulfillment centers and cross-docking facilities are interconnected logistics strategies that enhance supply chain efficiency by minimizing storage time and expediting order fulfillment. Micro-fulfillment centers use automated systems near urban areas to quickly process e-commerce orders, while cross-docking facilities streamline distribution by transferring goods directly from inbound to outbound transportation without long-term storage. Together, they reduce handling costs, shorten delivery times, and improve inventory turnover for retailers and logistics providers.

Key Terms

Transshipment

Cross-docking facilities streamline transshipment by directly transferring inbound goods to outbound transportation with minimal storage, enhancing speed and reducing inventory costs. Micro-fulfillment centers support transshipment by enabling rapid order processing and localized distribution, often within urban settings, to meet e-commerce demand efficiently. Explore detailed strategies and operational advantages of both to optimize your supply chain transshipment processes.

Last-mile delivery

Cross-docking facilities streamline last-mile delivery by minimizing storage time, enabling faster inventory turnover and reducing handling costs through direct transfer between inbound and outbound transportation. Micro-fulfillment centers, strategically located close to urban consumers, leverage automation and small footprints to expedite order processing and enhance delivery speed for e-commerce fulfillment. Explore the advantages and operational nuances of these two logistics models to optimize last-mile delivery efficiency.

Inventory holding

Cross-docking facilities minimize inventory holding by rapidly transferring goods from inbound to outbound transportation without long-term storage, thereby reducing carrying costs and improving supply chain efficiency. In contrast, micro-fulfillment centers maintain higher inventory levels closer to end consumers to enable faster order fulfillment, which requires strategic inventory management to balance space constraints and service speed. Explore deeper insights into how these models impact operational costs and customer satisfaction.

Source and External Links

Understanding cross-docking: A comprehensive guide - Cross-docking facilities are designed with layouts like U-, I-, or L-shaped warehouses to minimize distance and maximize efficiency by quickly transferring goods from receiving to dispatch, often using automation and advanced scheduling to streamline operations with minimal storage time.

How Does Cross Docking Work in Industrial Real Estate? - Cross-docking facilities feature opposite loading docks allowing goods to be transferred almost directly from inbound to outbound trucks, reducing storage needs and operational costs, while facing challenges such as adequate space, equipment, infrastructure, and safety requirements.

What is Cross-Docking? Warehousing Benefits & Strategies - Cross-docking facilities function as sorting centers with minimal storage, deploying methods such as continuous cross-docking, consolidation, and de-consolidation to efficiently handle inventory flow tailored to business needs and customer demands.

dowidth.com

dowidth.com