Pick-to-light systems enhance order fulfillment by guiding operators with illuminated indicators at storage locations, boosting accuracy and speed in manual picking processes. Goods-to-person systems automate the delivery of products directly to workers through conveyors or robotic shuttles, significantly reducing travel time and increasing throughput in high-volume warehouses. Explore how integrating pick-to-light and goods-to-person technologies can optimize logistics efficiency and meet evolving supply chain demands.

Why it is important

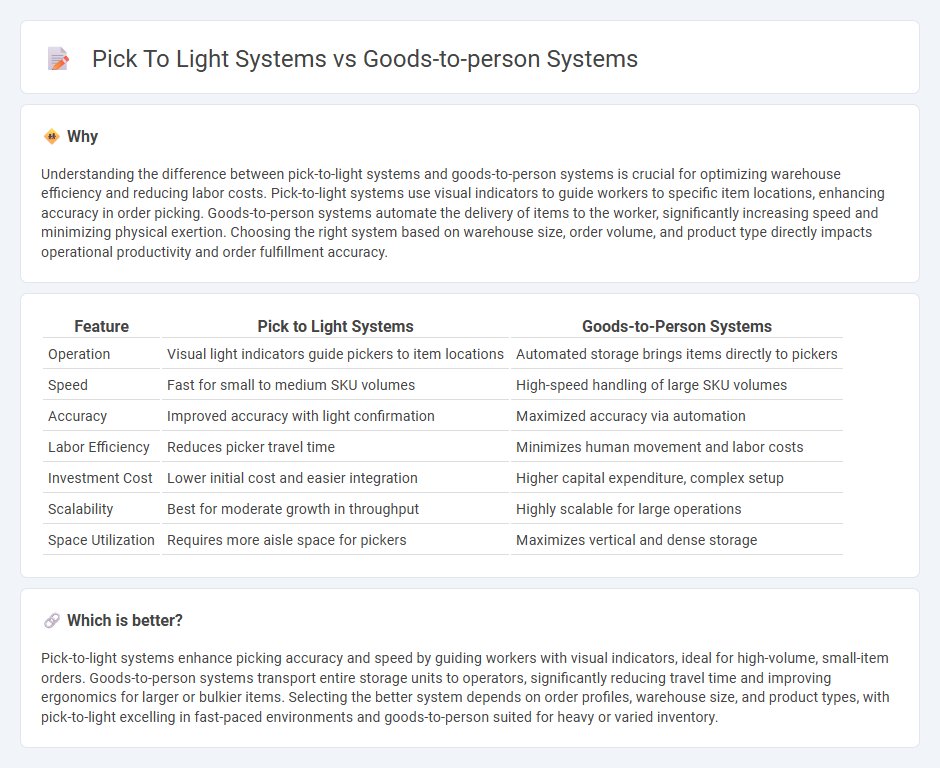

Understanding the difference between pick-to-light systems and goods-to-person systems is crucial for optimizing warehouse efficiency and reducing labor costs. Pick-to-light systems use visual indicators to guide workers to specific item locations, enhancing accuracy in order picking. Goods-to-person systems automate the delivery of items to the worker, significantly increasing speed and minimizing physical exertion. Choosing the right system based on warehouse size, order volume, and product type directly impacts operational productivity and order fulfillment accuracy.

Comparison Table

| Feature | Pick to Light Systems | Goods-to-Person Systems |

|---|---|---|

| Operation | Visual light indicators guide pickers to item locations | Automated storage brings items directly to pickers |

| Speed | Fast for small to medium SKU volumes | High-speed handling of large SKU volumes |

| Accuracy | Improved accuracy with light confirmation | Maximized accuracy via automation |

| Labor Efficiency | Reduces picker travel time | Minimizes human movement and labor costs |

| Investment Cost | Lower initial cost and easier integration | Higher capital expenditure, complex setup |

| Scalability | Best for moderate growth in throughput | Highly scalable for large operations |

| Space Utilization | Requires more aisle space for pickers | Maximizes vertical and dense storage |

Which is better?

Pick-to-light systems enhance picking accuracy and speed by guiding workers with visual indicators, ideal for high-volume, small-item orders. Goods-to-person systems transport entire storage units to operators, significantly reducing travel time and improving ergonomics for larger or bulkier items. Selecting the better system depends on order profiles, warehouse size, and product types, with pick-to-light excelling in fast-paced environments and goods-to-person suited for heavy or varied inventory.

Connection

Pick-to-light systems and Goods-to-person systems are interconnected through their shared goal of enhancing warehouse picking efficiency and accuracy. Pick-to-light technology uses illuminated displays to guide operators to specific storage locations, while Goods-to-person systems automate the delivery of items directly to the picker's station. Integration of these systems optimizes order fulfillment by reducing travel time and minimizing errors in high-volume logistics operations.

Key Terms

Automation

Goods-to-person systems enhance automation by using robotic shuttles or conveyors to deliver items directly to operators, significantly reducing walking time and increasing picking accuracy. Pick to light systems improve manual picking efficiency by utilizing light indicators to guide workers to the correct items, optimizing speed but relying more on human interaction. Explore the latest advancements in warehouse automation technologies to determine the best fit for your operation.

Order Picking

Goods-to-person systems enhance order picking efficiency by automating the retrieval of items directly to the worker, minimizing travel time and reducing errors in high-volume warehouses. Pick to light systems improve accuracy and speed by guiding operators with illuminated displays at pick locations, ideal for environments with diverse SKUs and smaller order sizes. Explore the detailed performance metrics and suitability of each system to optimize your order fulfillment process.

Efficiency

Goods-to-person systems significantly enhance efficiency by automating the retrieval process, reducing travel time for workers and increasing order accuracy through robotic delivery. Pick to light systems improve picking speed and accuracy by using illuminated indicators to guide operators to specific items, minimizing errors and training time. Explore the benefits of each system to determine the optimal solution for your warehouse efficiency.

Source and External Links

What is Goods-to-Person Order Fulfillment (G2P)? A Guide - AutoStore - Goods-to-Person (G2P) is a warehousing strategy where items are automatically brought to a stationary worker's picking station, reducing travel time and optimizing the picking process by using robots, conveyors, or shuttles to retrieve and deliver goods directly.

Goods-to-Person Order Fulfillment | Item Picking - Bastian Solutions - GTP systems combine automated storage and retrieval with ergonomic picking, enhancing accuracy and efficiency by bringing small or lightweight products directly to the operator, eliminating walking and reducing errors in high-demand environments.

The Many Benefits of Goods-to-Person Automation - Raymond West - GTP automation reduces human travel and error by using automated storage and retrieval systems or autonomous mobile robots to deliver goods to pickers, enabling faster fulfillment and higher productivity for e-commerce and just-in-time ordering requirements.

dowidth.com

dowidth.com