Reverse logistics focuses on the process of moving goods from their final destination back to the manufacturer for return, repair, or recycling, optimizing waste reduction and resource recovery. Closed-loop supply chains integrate forward and reverse flows, ensuring products and materials continuously cycle within the system to maximize sustainability and cost efficiency. Explore more to understand how both strategies improve supply chain resilience and environmental impact.

Why it is important

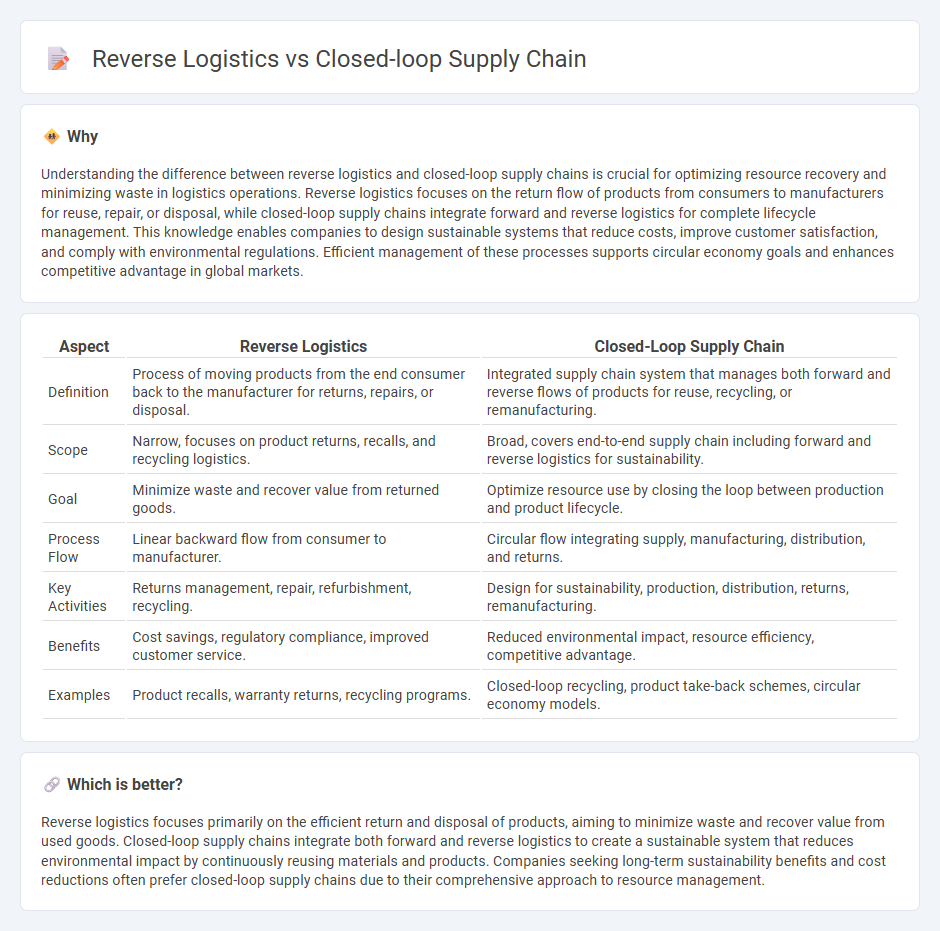

Understanding the difference between reverse logistics and closed-loop supply chains is crucial for optimizing resource recovery and minimizing waste in logistics operations. Reverse logistics focuses on the return flow of products from consumers to manufacturers for reuse, repair, or disposal, while closed-loop supply chains integrate forward and reverse logistics for complete lifecycle management. This knowledge enables companies to design sustainable systems that reduce costs, improve customer satisfaction, and comply with environmental regulations. Efficient management of these processes supports circular economy goals and enhances competitive advantage in global markets.

Comparison Table

| Aspect | Reverse Logistics | Closed-Loop Supply Chain |

|---|---|---|

| Definition | Process of moving products from the end consumer back to the manufacturer for returns, repairs, or disposal. | Integrated supply chain system that manages both forward and reverse flows of products for reuse, recycling, or remanufacturing. |

| Scope | Narrow, focuses on product returns, recalls, and recycling logistics. | Broad, covers end-to-end supply chain including forward and reverse logistics for sustainability. |

| Goal | Minimize waste and recover value from returned goods. | Optimize resource use by closing the loop between production and product lifecycle. |

| Process Flow | Linear backward flow from consumer to manufacturer. | Circular flow integrating supply, manufacturing, distribution, and returns. |

| Key Activities | Returns management, repair, refurbishment, recycling. | Design for sustainability, production, distribution, returns, remanufacturing. |

| Benefits | Cost savings, regulatory compliance, improved customer service. | Reduced environmental impact, resource efficiency, competitive advantage. |

| Examples | Product recalls, warranty returns, recycling programs. | Closed-loop recycling, product take-back schemes, circular economy models. |

Which is better?

Reverse logistics focuses primarily on the efficient return and disposal of products, aiming to minimize waste and recover value from used goods. Closed-loop supply chains integrate both forward and reverse logistics to create a sustainable system that reduces environmental impact by continuously reusing materials and products. Companies seeking long-term sustainability benefits and cost reductions often prefer closed-loop supply chains due to their comprehensive approach to resource management.

Connection

Reverse logistics and closed-loop supply chains are interconnected through their focus on reclaiming, repairing, recycling, and reusing products and materials to minimize waste and maximize resource efficiency. Reverse logistics encompasses the processes involved in returning goods from customers to manufacturers or distributors for remanufacturing or disposal, which is a critical component of closed-loop supply chains designed to create sustainable, circular systems. Implementing these strategies enhances supply chain resilience, reduces environmental impact, and supports regulatory compliance in industries such as electronics, automotive, and retail.

Key Terms

Product Recovery

Closed-loop supply chain integrates forward and reverse logistics to enable efficient product recovery, reuse, and recycling, creating sustainable value throughout the product lifecycle. Reverse logistics specifically addresses the return flow of products for refurbishment, remanufacturing, or proper disposal, forming a crucial component of the closed-loop system. Explore the distinctions and synergies within product recovery to enhance supply chain sustainability and efficiency.

End-of-Life Management

Closed-loop supply chain integrates end-of-life management by reclaiming products for refurbishment, remanufacturing, or recycling, aiming to create a sustainable cycle that reduces waste and conserves resources. Reverse logistics focuses primarily on the efficient return and proper disposal of products at the end of their lifecycle, emphasizing transportation and logistics processes. Explore how these strategies optimize sustainability and cost-efficiency in managing product returns and disposal.

Circular Economy

Closed-loop supply chain integrates product returns, remanufacturing, and recycling into the overall supply chain to minimize waste and resource consumption, driving Circular Economy objectives. Reverse logistics specifically manages the process of moving goods from consumers back to producers for refurbishment, recycling, or proper disposal. Explore deeper insights on how these strategies enhance sustainability and economic efficiency in Circular Economy frameworks.

Source and External Links

What is Closed-Loop Supply Chain - Glossary of Procurement - A Closed-Loop Supply Chain (CLSC) integrates the forward flow of products with their reverse flow, involving activities like repairing, remanufacturing, recycling, and refurbishing to reuse products or components, thereby maximizing value and minimizing waste, while delivering benefits such as resource efficiency, sustainability, cost reduction, regulatory compliance, and competitive advantage.

What is a Closed-Loop Supply Chain? - Revolutionized - A closed-loop supply chain combines forward and reverse logistics by reusing or recycling products after their initial use to reduce waste and support a circular economy, making supply networks more sustainable and efficient.

Closed Loop Supply Chain (CLSC): Meaning & Examples - A closed-loop supply chain manages the entire product lifecycle by controlling the flow of goods from supplier to customer and returning used products for reuse, recycling, or disposal, often enhanced by automation for increased efficiency, error reduction, and real-time tracking.

dowidth.com

dowidth.com