Container pooling enhances efficiency by allowing multiple shippers to share standardized containers, reducing costs and environmental impact through better container utilization. Freight consolidation combines smaller shipments into one larger load, optimizing transportation and lowering shipping expenses while improving delivery speed. Explore these strategies further to understand their distinct benefits and implementation in logistics management.

Why it is important

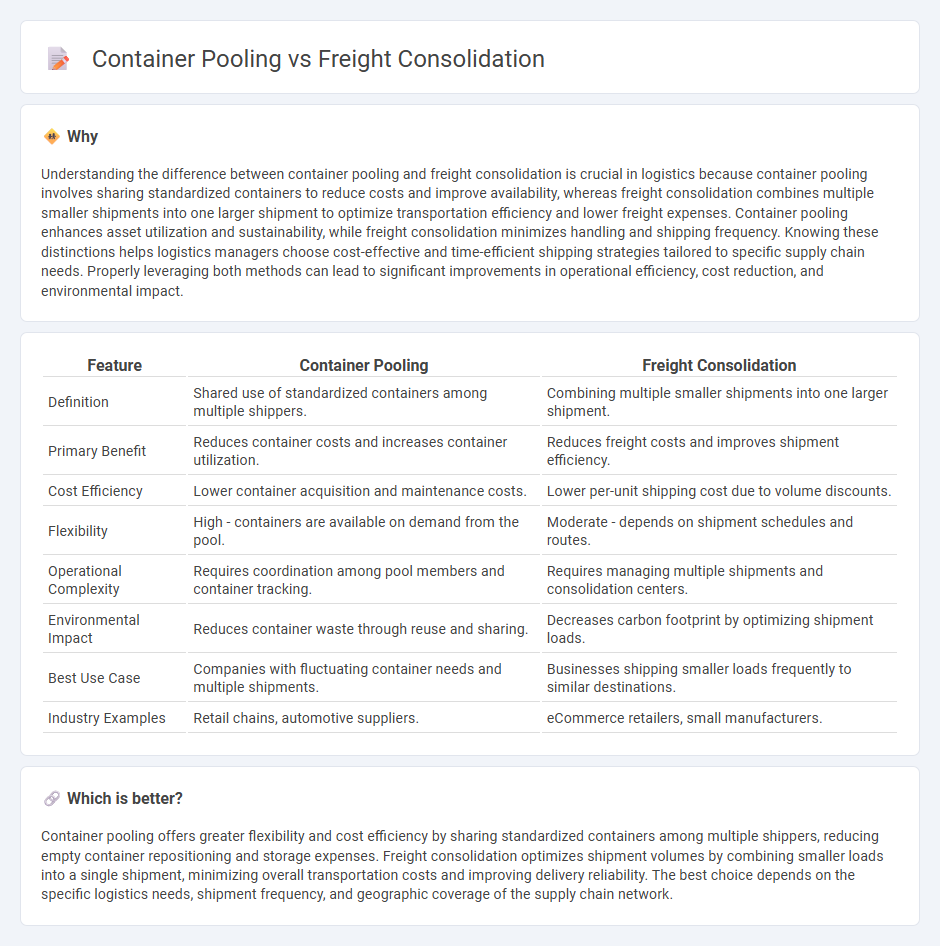

Understanding the difference between container pooling and freight consolidation is crucial in logistics because container pooling involves sharing standardized containers to reduce costs and improve availability, whereas freight consolidation combines multiple smaller shipments into one larger shipment to optimize transportation efficiency and lower freight expenses. Container pooling enhances asset utilization and sustainability, while freight consolidation minimizes handling and shipping frequency. Knowing these distinctions helps logistics managers choose cost-effective and time-efficient shipping strategies tailored to specific supply chain needs. Properly leveraging both methods can lead to significant improvements in operational efficiency, cost reduction, and environmental impact.

Comparison Table

| Feature | Container Pooling | Freight Consolidation |

|---|---|---|

| Definition | Shared use of standardized containers among multiple shippers. | Combining multiple smaller shipments into one larger shipment. |

| Primary Benefit | Reduces container costs and increases container utilization. | Reduces freight costs and improves shipment efficiency. |

| Cost Efficiency | Lower container acquisition and maintenance costs. | Lower per-unit shipping cost due to volume discounts. |

| Flexibility | High - containers are available on demand from the pool. | Moderate - depends on shipment schedules and routes. |

| Operational Complexity | Requires coordination among pool members and container tracking. | Requires managing multiple shipments and consolidation centers. |

| Environmental Impact | Reduces container waste through reuse and sharing. | Decreases carbon footprint by optimizing shipment loads. |

| Best Use Case | Companies with fluctuating container needs and multiple shipments. | Businesses shipping smaller loads frequently to similar destinations. |

| Industry Examples | Retail chains, automotive suppliers. | eCommerce retailers, small manufacturers. |

Which is better?

Container pooling offers greater flexibility and cost efficiency by sharing standardized containers among multiple shippers, reducing empty container repositioning and storage expenses. Freight consolidation optimizes shipment volumes by combining smaller loads into a single shipment, minimizing overall transportation costs and improving delivery reliability. The best choice depends on the specific logistics needs, shipment frequency, and geographic coverage of the supply chain network.

Connection

Container pooling optimizes the use of shipping containers by sharing them among multiple companies, reducing empty container movements and lowering costs. Freight consolidation combines smaller shipments into a single load to maximize container capacity and improve shipping efficiency. Together, these practices enhance supply chain sustainability and reduce overall logistics expenses by minimizing wasted space and resources.

Key Terms

Freight Consolidation:

Freight consolidation improves shipping efficiency by combining multiple smaller shipments into one larger load, reducing transportation costs and minimizing environmental impact. This method leverages economies of scale, optimizing cargo space utilization and streamlining logistics operations for businesses. Discover how freight consolidation can enhance supply chain performance and reduce expenses.

Less-than-Truckload (LTL)

Freight consolidation in Less-than-Truckload (LTL) shipping merges multiple smaller shipments to maximize truck capacity, reducing transportation costs and improving delivery efficiency. Container pooling involves sharing standardized containers among multiple shippers, optimizing container utilization and minimizing empty container repositioning expenses. Explore more to understand how these strategies enhance LTL logistics and reduce supply chain expenses.

Cross-docking

Freight consolidation combines multiple shipments into a single load to optimize space and reduce transportation costs, while container pooling involves sharing standardized containers among multiple shippers to enhance equipment utilization and reduce empty container repositioning. Cross-docking acts as a critical process in both strategies by facilitating rapid transfer of freight between inbound and outbound vehicles, minimizing storage time and improving supply chain efficiency. Discover how integrating cross-docking with these methods can drive cost savings and operational excellence in logistics.

Source and External Links

What is Freight Consolidation? Trinity Explains. - Freight consolidation is the process of combining multiple smaller shipments within a region into a single larger load, allowing shippers to save money by paying bulk rates and optimizing logistics while still delivering smaller portions regionally at the destination.

Freight Consolidation: What It Is and When to Use It - Ware2Go - Freight consolidation reduces shipping costs by combining shipments to maximize volume, enabling businesses to benefit from full truckload pricing, improve supply chain performance, and reduce delivery complexity and delays.

Freight Consolidation: The Benefits and Drawbacks - Averitt - Freight consolidation combines multiple less-than-truckload shipments into full truckload shipments to reduce overall shipping costs per unit and decrease freight damage by limiting handling.

dowidth.com

dowidth.com