Cold chain logistics focuses on the transportation and storage of temperature-sensitive products such as pharmaceuticals, perishable foods, and chemicals, ensuring strict temperature control from origin to destination. Warehouse logistics, on the other hand, involves the management, storage, and distribution of goods in warehouses, emphasizing inventory optimization, space utilization, and efficient order fulfillment. Explore the key differences and benefits of cold chain logistics versus warehouse logistics to optimize your supply chain strategy.

Why it is important

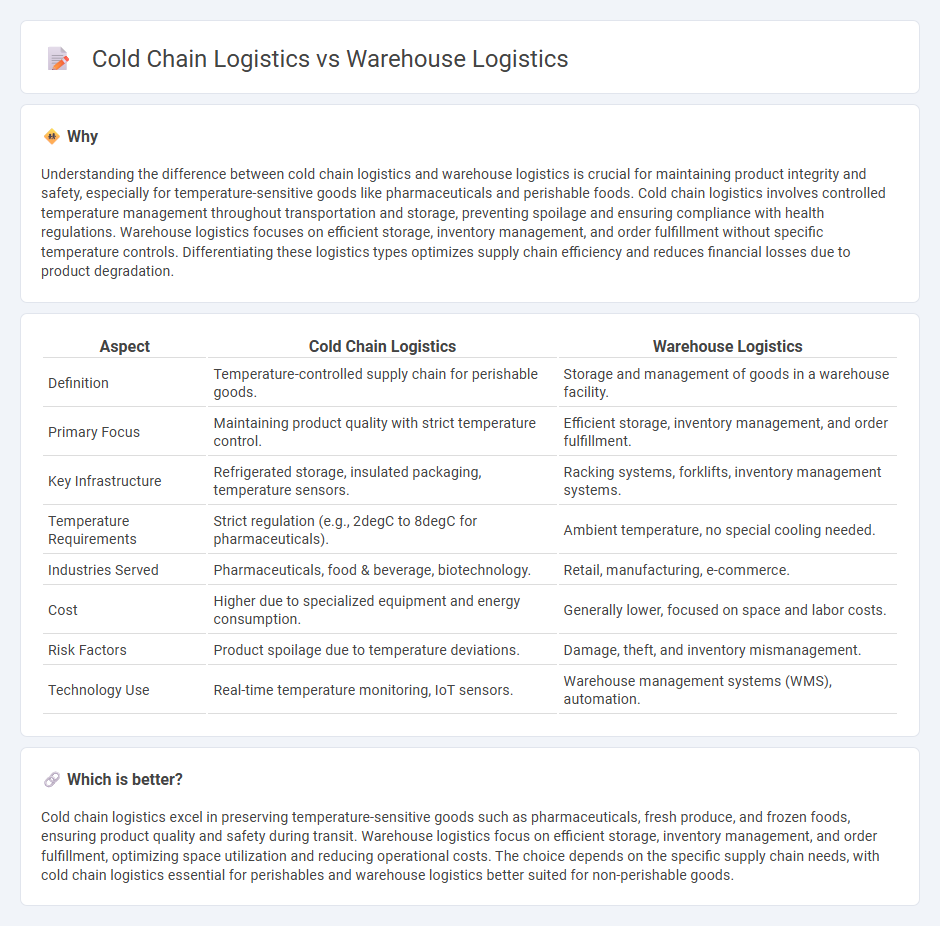

Understanding the difference between cold chain logistics and warehouse logistics is crucial for maintaining product integrity and safety, especially for temperature-sensitive goods like pharmaceuticals and perishable foods. Cold chain logistics involves controlled temperature management throughout transportation and storage, preventing spoilage and ensuring compliance with health regulations. Warehouse logistics focuses on efficient storage, inventory management, and order fulfillment without specific temperature controls. Differentiating these logistics types optimizes supply chain efficiency and reduces financial losses due to product degradation.

Comparison Table

| Aspect | Cold Chain Logistics | Warehouse Logistics |

|---|---|---|

| Definition | Temperature-controlled supply chain for perishable goods. | Storage and management of goods in a warehouse facility. |

| Primary Focus | Maintaining product quality with strict temperature control. | Efficient storage, inventory management, and order fulfillment. |

| Key Infrastructure | Refrigerated storage, insulated packaging, temperature sensors. | Racking systems, forklifts, inventory management systems. |

| Temperature Requirements | Strict regulation (e.g., 2degC to 8degC for pharmaceuticals). | Ambient temperature, no special cooling needed. |

| Industries Served | Pharmaceuticals, food & beverage, biotechnology. | Retail, manufacturing, e-commerce. |

| Cost | Higher due to specialized equipment and energy consumption. | Generally lower, focused on space and labor costs. |

| Risk Factors | Product spoilage due to temperature deviations. | Damage, theft, and inventory mismanagement. |

| Technology Use | Real-time temperature monitoring, IoT sensors. | Warehouse management systems (WMS), automation. |

Which is better?

Cold chain logistics excel in preserving temperature-sensitive goods such as pharmaceuticals, fresh produce, and frozen foods, ensuring product quality and safety during transit. Warehouse logistics focus on efficient storage, inventory management, and order fulfillment, optimizing space utilization and reducing operational costs. The choice depends on the specific supply chain needs, with cold chain logistics essential for perishables and warehouse logistics better suited for non-perishable goods.

Connection

Cold chain logistics and warehouse logistics are interconnected through temperature-controlled storage and handling processes that ensure the integrity of perishable goods. Specialized cold storage facilities within warehouses maintain consistent low temperatures crucial for pharmaceuticals, food products, and other temperature-sensitive items. Efficient coordination between cold chain systems and warehouse management optimizes inventory turnover, reduces spoilage, and enhances supply chain reliability.

Key Terms

**Warehouse Logistics:**

Warehouse logistics involves managing the efficient storage, handling, and movement of goods within warehouses, focusing on inventory control, order fulfillment, and space optimization. Advanced warehouse management systems (WMS) enhance productivity by integrating real-time data tracking and automation for streamlined operations. Explore more about how warehouse logistics drives supply chain efficiency and cost reduction.

Inventory Management

Warehouse logistics manages inventory by optimizing storage, handling, and retrieval processes to ensure efficient stock turnover and space utilization. Cold chain logistics specializes in maintaining strict temperature controls for perishable goods, ensuring product quality and compliance throughout storage and transportation. Explore the critical differences and best practices in inventory management within these logistics sectors to enhance operational efficiency.

Order Fulfillment

Warehouse logistics centers on efficient storage, inventory management, and rapid picking and packing to streamline order fulfillment processes. Cold chain logistics adds the critical layer of temperature control during storage and transportation, ensuring perishable goods like pharmaceuticals and food products remain compliant with safety standards. Explore detailed strategies to optimize order fulfillment across both logistics types for enhanced supply chain performance.

Source and External Links

What Is Warehouse Logistics? Components, Challenges & Tips - Warehouse logistics involves organizing and managing the storage and movement of goods in a warehouse through components like warehouse management, warehouse operations, and warehouse management systems (WMS), which optimize efficiency and inventory accuracy.

Warehousing and Logistics: Key Strategies for Effective Supply Chains - Warehouse logistics solutions include inventory management, order fulfillment, and cross-docking to streamline the flow of goods from storage to delivery while integrating with eCommerce platforms and third-party logistics providers (3PL) for efficiency.

What Is Warehouse Logistics? How To Manage a Warehouse (2024) - Effective warehouse logistics manages goods flow inside warehouses by leveraging warehouse management systems, optimizing layout, streamlining picking, and using technology and training to improve operational efficiency and reduce costs.

dowidth.com

dowidth.com