Pick and pack logistics involves sorting and packaging products in a warehouse before shipping them to retailers or customers, optimizing inventory management and order accuracy. Direct Store Delivery (DSD) bypasses warehouses by delivering products directly from manufacturers to retail stores, ensuring faster restocking and fresher goods. Explore the advantages and applications of pick and pack versus DSD to enhance your supply chain efficiency.

Why it is important

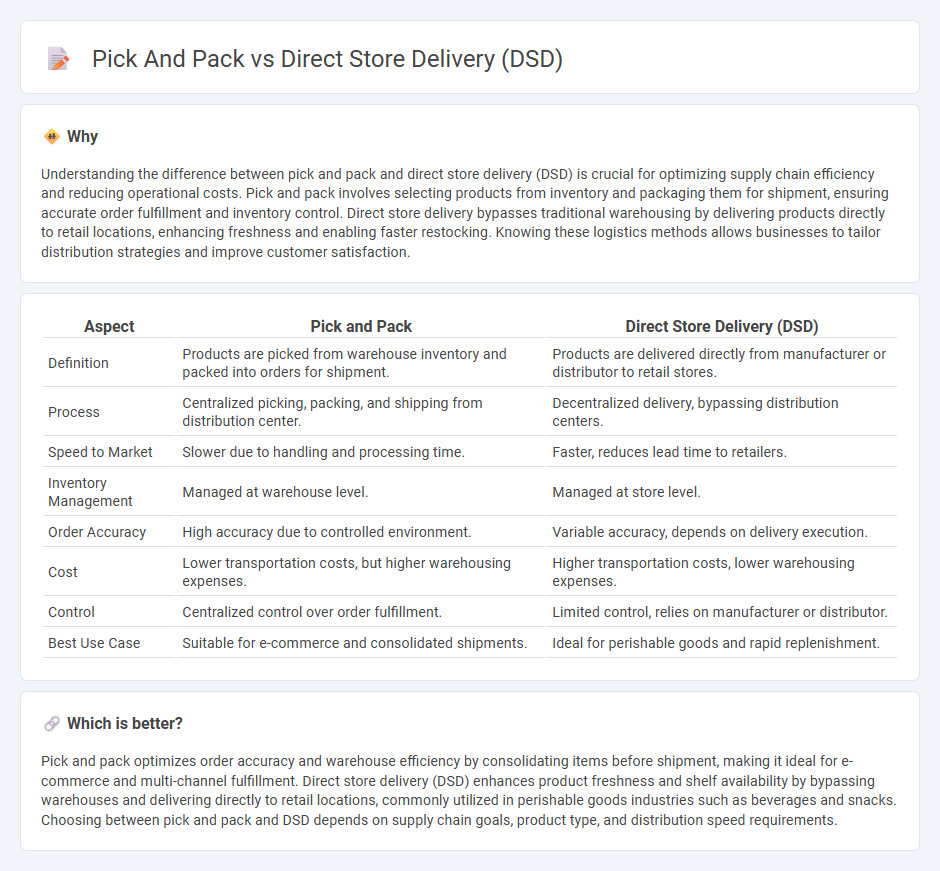

Understanding the difference between pick and pack and direct store delivery (DSD) is crucial for optimizing supply chain efficiency and reducing operational costs. Pick and pack involves selecting products from inventory and packaging them for shipment, ensuring accurate order fulfillment and inventory control. Direct store delivery bypasses traditional warehousing by delivering products directly to retail locations, enhancing freshness and enabling faster restocking. Knowing these logistics methods allows businesses to tailor distribution strategies and improve customer satisfaction.

Comparison Table

| Aspect | Pick and Pack | Direct Store Delivery (DSD) |

|---|---|---|

| Definition | Products are picked from warehouse inventory and packed into orders for shipment. | Products are delivered directly from manufacturer or distributor to retail stores. |

| Process | Centralized picking, packing, and shipping from distribution center. | Decentralized delivery, bypassing distribution centers. |

| Speed to Market | Slower due to handling and processing time. | Faster, reduces lead time to retailers. |

| Inventory Management | Managed at warehouse level. | Managed at store level. |

| Order Accuracy | High accuracy due to controlled environment. | Variable accuracy, depends on delivery execution. |

| Cost | Lower transportation costs, but higher warehousing expenses. | Higher transportation costs, lower warehousing expenses. |

| Control | Centralized control over order fulfillment. | Limited control, relies on manufacturer or distributor. |

| Best Use Case | Suitable for e-commerce and consolidated shipments. | Ideal for perishable goods and rapid replenishment. |

Which is better?

Pick and pack optimizes order accuracy and warehouse efficiency by consolidating items before shipment, making it ideal for e-commerce and multi-channel fulfillment. Direct store delivery (DSD) enhances product freshness and shelf availability by bypassing warehouses and delivering directly to retail locations, commonly utilized in perishable goods industries such as beverages and snacks. Choosing between pick and pack and DSD depends on supply chain goals, product type, and distribution speed requirements.

Connection

Pick and pack processes streamline order fulfillment by selecting items from inventory and packaging them efficiently to meet customer requirements. Direct Store Delivery (DSD) relies on these processes to ensure accurate, timely shipments directly to retail locations, reducing handling and inventory holding costs. Integrating pick and pack with DSD enhances supply chain efficiency by minimizing errors and improving product availability on store shelves.

Key Terms

Distribution Channel

Direct Store Delivery (DSD) leverages a distribution channel where manufacturers ship products directly to retail stores, bypassing central warehouses for faster replenishment and improved product freshness. In contrast, pick and pack operates through a centralized warehouse distribution channel, where orders are consolidated, picked, and packed before being shipped to retail locations or customers. Explore how these distribution channels impact supply chain efficiency and customer satisfaction to optimize your logistics strategy.

Inventory Handling

Direct Store Delivery (DSD) streamlines inventory handling by allowing products to be delivered directly from manufacturers to retail stores, reducing warehousing needs and minimizing stockouts. Pick and pack methods involve central warehouses where inventory is stored, orders are picked based on demand, and then packed for shipment, enabling precise inventory management and order accuracy. Explore each approach's inventory advantages to optimize your supply chain efficiency.

Order Fulfillment

Direct Store Delivery (DSD) enables suppliers to deliver products directly to retail stores, bypassing central warehouses and expediting order fulfillment for time-sensitive goods. Pick and pack involves selecting products from a centralized warehouse and packaging them for shipment, optimizing inventory management and reducing distribution costs. Explore the advantages and operational differences between DSD and pick and pack to enhance your order fulfillment strategy.

Source and External Links

What Is Direct-Store Delivery (DSD)? What Are Its Benefits? - Direct-Store Delivery (DSD) is a distribution model where manufacturers deliver products directly to retail stores, bypassing traditional distribution centers.

What is Direct Store Delivery? Logistics Glossary - Direct-store delivery (DSD) involves shipping products directly from a supplier to a retail store, improving efficiency and reducing labor costs.

Direct Store Delivery | ORTEC - Direct Store Delivery (DSD) is a method where products are delivered directly from suppliers to retail stores, requiring optimizations for efficiency and cost savings.

dowidth.com

dowidth.com