Green corridor logistics minimizes carbon emissions by creating dedicated routes for eco-friendly transportation, enhancing sustainability in supply chains. Cross-docking optimizes inventory flow by directly transferring goods from inbound to outbound vehicles, reducing storage time and operational costs. Explore further to understand how these innovative strategies reshape efficient and sustainable logistics management.

Why it is important

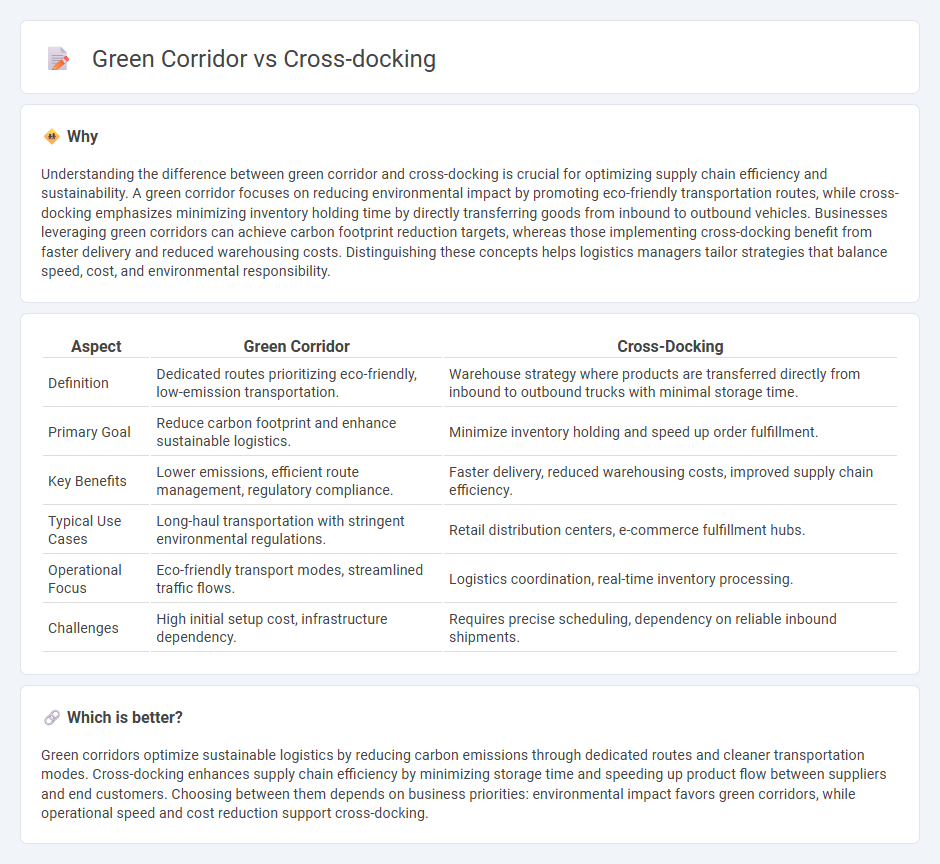

Understanding the difference between green corridor and cross-docking is crucial for optimizing supply chain efficiency and sustainability. A green corridor focuses on reducing environmental impact by promoting eco-friendly transportation routes, while cross-docking emphasizes minimizing inventory holding time by directly transferring goods from inbound to outbound vehicles. Businesses leveraging green corridors can achieve carbon footprint reduction targets, whereas those implementing cross-docking benefit from faster delivery and reduced warehousing costs. Distinguishing these concepts helps logistics managers tailor strategies that balance speed, cost, and environmental responsibility.

Comparison Table

| Aspect | Green Corridor | Cross-Docking |

|---|---|---|

| Definition | Dedicated routes prioritizing eco-friendly, low-emission transportation. | Warehouse strategy where products are transferred directly from inbound to outbound trucks with minimal storage time. |

| Primary Goal | Reduce carbon footprint and enhance sustainable logistics. | Minimize inventory holding and speed up order fulfillment. |

| Key Benefits | Lower emissions, efficient route management, regulatory compliance. | Faster delivery, reduced warehousing costs, improved supply chain efficiency. |

| Typical Use Cases | Long-haul transportation with stringent environmental regulations. | Retail distribution centers, e-commerce fulfillment hubs. |

| Operational Focus | Eco-friendly transport modes, streamlined traffic flows. | Logistics coordination, real-time inventory processing. |

| Challenges | High initial setup cost, infrastructure dependency. | Requires precise scheduling, dependency on reliable inbound shipments. |

Which is better?

Green corridors optimize sustainable logistics by reducing carbon emissions through dedicated routes and cleaner transportation modes. Cross-docking enhances supply chain efficiency by minimizing storage time and speeding up product flow between suppliers and end customers. Choosing between them depends on business priorities: environmental impact favors green corridors, while operational speed and cost reduction support cross-docking.

Connection

Green corridors minimize carbon emissions by streamlining routes and consolidating shipments, while cross-docking reduces storage time and handling, enhancing overall supply chain efficiency. Together, these logistics strategies optimize freight flow, lower transportation costs, and support sustainable delivery practices. The integration of green corridors with cross-docking enables faster, environmentally friendly distribution networks that decrease fuel consumption and waste.

Key Terms

Cross-docking:

Cross-docking is a logistics strategy where incoming shipments are directly transferred from inbound to outbound transportation with minimal storage time, optimizing supply chain efficiency and reducing inventory costs. This method improves delivery speed and lowers warehouse demands by eliminating prolonged storage, making it ideal for perishable goods and time-sensitive products. Explore detailed advantages and implementation techniques of cross-docking to enhance your logistics operations.

Transshipment

Cross-docking minimizes storage time by directly transferring goods from inbound to outbound transportation, enhancing efficiency in transshipment operations. Green corridors prioritize environmental sustainability by optimizing routes to reduce carbon emissions during transshipment processes. Discover how these strategies transform logistics and transshipment by exploring their detailed benefits and applications.

Just-in-Time (JIT)

Cross-docking minimizes storage time by directly transferring goods from inbound to outbound transportation, enhancing Just-in-Time (JIT) efficiency through rapid inventory turnover. Green corridors optimize logistics routes with reduced emissions and streamlined customs procedures, supporting JIT by ensuring timely and sustainable deliveries. Explore the benefits of integrating cross-docking and green corridors to advance your JIT supply chain strategy.

Source and External Links

Cross Docking: Definition, History, and Process - Inbound Logistics - Cross docking is a shipping method transferring goods directly from one transportation mode to another with minimal storage, using methods like continuous cross docking, consolidation, and de-consolidation to increase efficiency and speed.

What Is Cross-Docking? Definition, Types & Advantages - NetSuite - Cross-docking is a supply chain strategy that speeds delivery and reduces costs by moving goods directly from inbound to outbound vehicles with minimal warehouse storage and is used widely in retail, ecommerce, and manufacturing.

Understanding cross-docking: A comprehensive guide - Maersk - Cross-docking minimizes storage by transferring products quickly from suppliers to customers, with types including pre-distribution, post-distribution, continuous, consolidation, and deconsolidation, tailored to retail, manufacturing, and e-commerce needs.

dowidth.com

dowidth.com