Cold chain traceability leverages advanced IoT sensors and blockchain technology to monitor temperature-sensitive goods in real time, ensuring product integrity throughout transportation. Compliance management focuses on adhering to stringent regulatory standards like FDA and HACCP by maintaining accurate documentation and audit trails across the supply chain. Explore how integrating cold chain traceability with compliance management can optimize efficiency and reduce risk in logistics.

Why it is important

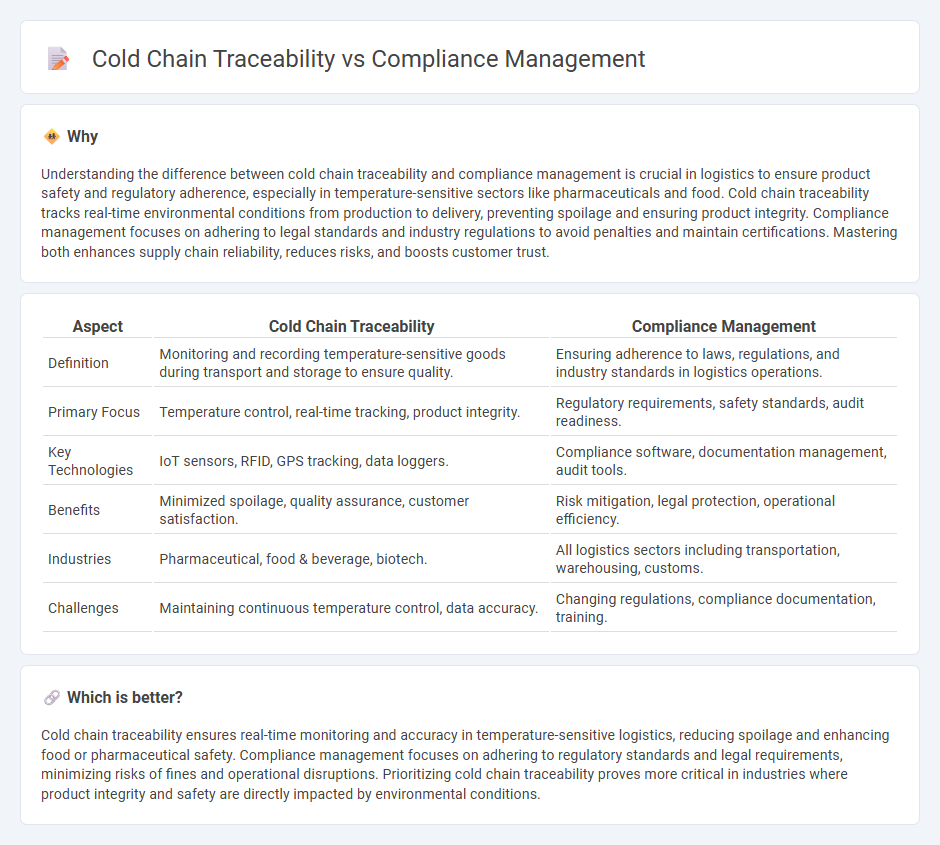

Understanding the difference between cold chain traceability and compliance management is crucial in logistics to ensure product safety and regulatory adherence, especially in temperature-sensitive sectors like pharmaceuticals and food. Cold chain traceability tracks real-time environmental conditions from production to delivery, preventing spoilage and ensuring product integrity. Compliance management focuses on adhering to legal standards and industry regulations to avoid penalties and maintain certifications. Mastering both enhances supply chain reliability, reduces risks, and boosts customer trust.

Comparison Table

| Aspect | Cold Chain Traceability | Compliance Management |

|---|---|---|

| Definition | Monitoring and recording temperature-sensitive goods during transport and storage to ensure quality. | Ensuring adherence to laws, regulations, and industry standards in logistics operations. |

| Primary Focus | Temperature control, real-time tracking, product integrity. | Regulatory requirements, safety standards, audit readiness. |

| Key Technologies | IoT sensors, RFID, GPS tracking, data loggers. | Compliance software, documentation management, audit tools. |

| Benefits | Minimized spoilage, quality assurance, customer satisfaction. | Risk mitigation, legal protection, operational efficiency. |

| Industries | Pharmaceutical, food & beverage, biotech. | All logistics sectors including transportation, warehousing, customs. |

| Challenges | Maintaining continuous temperature control, data accuracy. | Changing regulations, compliance documentation, training. |

Which is better?

Cold chain traceability ensures real-time monitoring and accuracy in temperature-sensitive logistics, reducing spoilage and enhancing food or pharmaceutical safety. Compliance management focuses on adhering to regulatory standards and legal requirements, minimizing risks of fines and operational disruptions. Prioritizing cold chain traceability proves more critical in industries where product integrity and safety are directly impacted by environmental conditions.

Connection

Cold chain traceability ensures real-time monitoring of temperature-sensitive products, maintaining quality and safety throughout the supply chain. Compliance management enforces industry regulations and standards, requiring detailed documentation and accountability for cold chain processes. Together, they mitigate risks of product spoilage and regulatory breaches, enhancing overall logistics efficiency and consumer trust.

Key Terms

Compliance management:

Compliance management ensures adherence to regulatory standards, reducing risk and enhancing operational efficiency across industries. It involves systematic monitoring, documentation, and reporting to meet legal and quality requirements, which is critical for avoiding costly penalties. Explore in-depth strategies and tools for optimizing compliance management to safeguard your business.

Regulatory standards

Compliance management ensures adherence to regulatory standards such as FDA, EU GMP, and ISO 22000 to avoid violations and maintain product safety. Cold chain traceability involves monitoring temperature, location, and handling conditions in real-time to meet specific regulatory requirements for perishable goods. Explore how integrating compliance management with cold chain traceability can optimize regulatory adherence and operational efficiency.

Auditing

Compliance management ensures adherence to regulatory standards by systematically reviewing processes and documentation, whereas cold chain traceability tracks temperature-sensitive products through every stage to maintain quality and safety. Auditing in compliance management involves comprehensive evaluations of operational protocols and risk controls, while cold chain traceability audits emphasize verifying temperature data integrity and shipment conditions. Explore detailed methodologies in both areas to enhance your auditing effectiveness and regulatory assurance.

Source and External Links

Compliance Management: Process, Regulations, and Tools - Compliance management is the process of aligning organizational policies with laws and regulations through identifying requirements, assessing current adherence, and developing policies to address gaps and maintain compliance.

What is Compliance Management? - It involves continuous monitoring and evaluation of systems to ensure adherence to legal standards, led by a compliance officer who implements training, audits, and corrective actions within a structured compliance program.

What is a Compliance Management System? - A compliance management system integrates policies, training, risk assessments, and reporting to meet regulatory requirements, with a focus on corrective action and continuous improvement coordinated across the organization.

dowidth.com

dowidth.com