Pick to light systems significantly enhance order fulfillment accuracy and speed by utilizing illuminated indicators that guide workers directly to items, reducing human error and increasing efficiency compared to traditional paper-based picking methods. Paper-based systems rely heavily on manual data entry and physical documentation, which can lead to slower processing times and higher chances of mistakes in busy warehouses. Explore how integrating pick to light technology can transform your supply chain operations and boost productivity.

Why it is important

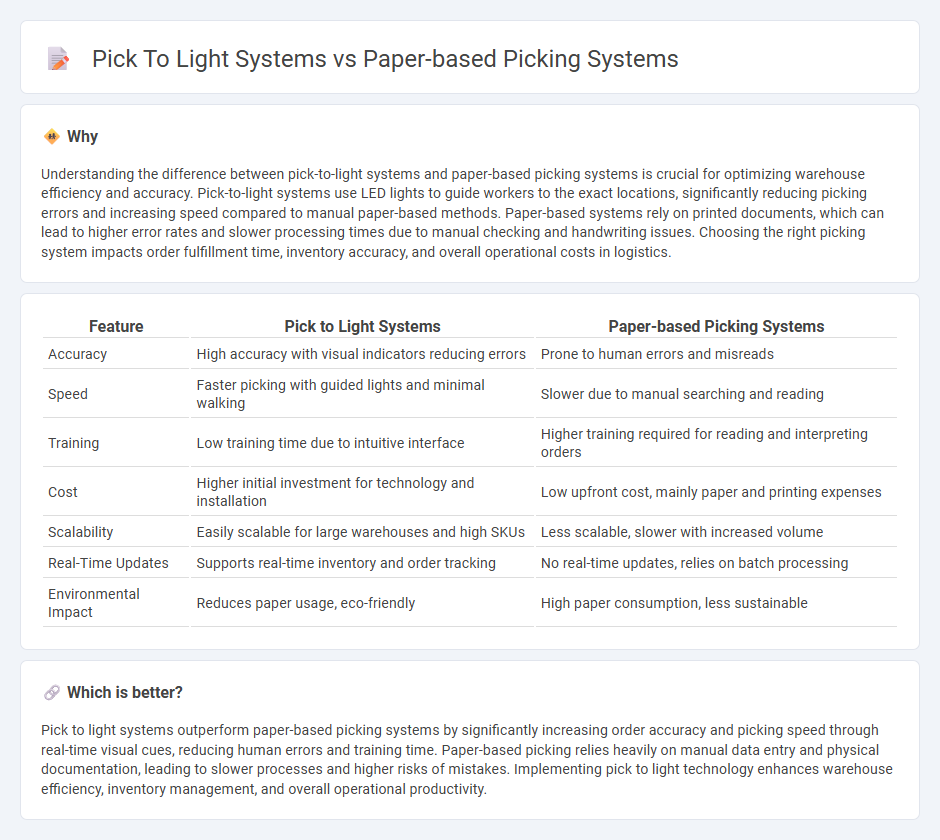

Understanding the difference between pick-to-light systems and paper-based picking systems is crucial for optimizing warehouse efficiency and accuracy. Pick-to-light systems use LED lights to guide workers to the exact locations, significantly reducing picking errors and increasing speed compared to manual paper-based methods. Paper-based systems rely on printed documents, which can lead to higher error rates and slower processing times due to manual checking and handwriting issues. Choosing the right picking system impacts order fulfillment time, inventory accuracy, and overall operational costs in logistics.

Comparison Table

| Feature | Pick to Light Systems | Paper-based Picking Systems |

|---|---|---|

| Accuracy | High accuracy with visual indicators reducing errors | Prone to human errors and misreads |

| Speed | Faster picking with guided lights and minimal walking | Slower due to manual searching and reading |

| Training | Low training time due to intuitive interface | Higher training required for reading and interpreting orders |

| Cost | Higher initial investment for technology and installation | Low upfront cost, mainly paper and printing expenses |

| Scalability | Easily scalable for large warehouses and high SKUs | Less scalable, slower with increased volume |

| Real-Time Updates | Supports real-time inventory and order tracking | No real-time updates, relies on batch processing |

| Environmental Impact | Reduces paper usage, eco-friendly | High paper consumption, less sustainable |

Which is better?

Pick to light systems outperform paper-based picking systems by significantly increasing order accuracy and picking speed through real-time visual cues, reducing human errors and training time. Paper-based picking relies heavily on manual data entry and physical documentation, leading to slower processes and higher risks of mistakes. Implementing pick to light technology enhances warehouse efficiency, inventory management, and overall operational productivity.

Connection

Pick-to-light systems streamline order fulfillment by using LED indicators to guide warehouse workers to the correct picking locations, enhancing accuracy and speed. Paper-based picking systems rely on printed pick lists, which can be integrated with pick-to-light technology by converting the paper instructions into digital signals that trigger lights at designated storage bins. Combining these systems optimizes picking efficiency by reducing human error associated with manual reading and increasing real-time inventory tracking capabilities.

Key Terms

Order Accuracy

Order accuracy in paper-based picking systems often suffers due to human errors in reading and writing, leading to mispicks and delays. Pick to light systems significantly improve accuracy by providing real-time visual guidance and reducing cognitive load on workers, resulting in fewer mistakes and faster order fulfillment. Explore the benefits of pick to light technology to enhance your warehouse order accuracy and efficiency.

Productivity

Paper-based picking systems rely on manual processes that often lead to slower order fulfillment and increased error rates, reducing overall productivity in warehouse operations. Pick to light systems use illuminated displays to guide pickers directly to items, significantly improving accuracy and speed by minimizing search time and reducing human errors. Explore how integrating pick to light technology can transform your warehouse productivity and efficiency.

Error Rate

Paper-based picking systems are prone to higher error rates due to manual data entry and lack of real-time verification, often resulting in inaccuracies in order fulfillment. Pick to light systems significantly reduce errors by guiding workers with visual cues, ensuring faster and more precise item selection with error rates reported as low as 1-2%. Explore further to understand how pick to light technology enhances accuracy and efficiency in warehouse operations.

Source and External Links

Paper Picking - Numina Group - Paper-based picking systems involve pickers using printed pick lists to manually locate and retrieve items for orders, commonly used in smaller warehouses but becoming less efficient as order volume and complexity increase due to longer pick paths and greater labor costs.

What is Pick by Paper? Logistics lexicon - proLogistik Group - Pick-by-paper is a basic order picking method using printed documents, which is cost-effective and easy to implement but suffers from high error rates, manual processing delays, and is not suitable for large-scale or just-in-time operations.

Why paper-picking is picking the pockets of your warehouse - Paper-based picking may suffice for small operations initially, but as business grows, it leads to inefficiencies such as increased travel time, lowered pick rates, and resource drain, highlighting the need to move towards more automated, digital picking solutions.

dowidth.com

dowidth.com