Pick to light systems enhance order accuracy and speed by using LED indicators that guide workers to the correct items, reducing errors and training time in warehouses. Conveyor-based picking systems streamline large-scale operations by automating the movement of goods, optimizing space, and minimizing manual handling for faster throughput. Discover how integrating these technologies can revolutionize your logistics efficiency and reduce operational costs.

Why it is important

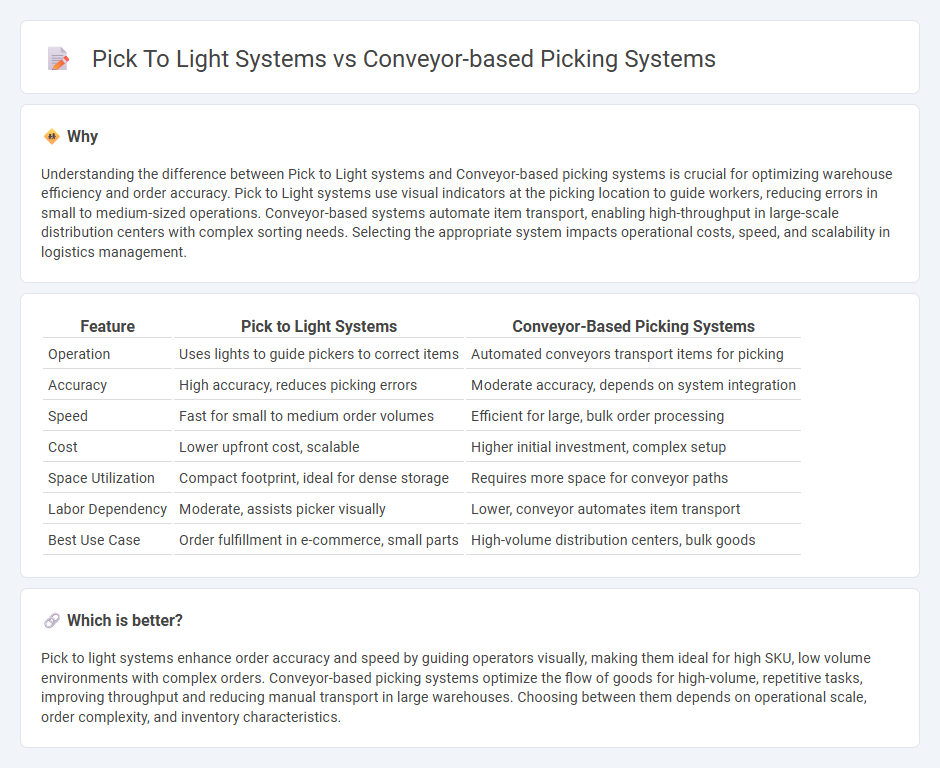

Understanding the difference between Pick to Light systems and Conveyor-based picking systems is crucial for optimizing warehouse efficiency and order accuracy. Pick to Light systems use visual indicators at the picking location to guide workers, reducing errors in small to medium-sized operations. Conveyor-based systems automate item transport, enabling high-throughput in large-scale distribution centers with complex sorting needs. Selecting the appropriate system impacts operational costs, speed, and scalability in logistics management.

Comparison Table

| Feature | Pick to Light Systems | Conveyor-Based Picking Systems |

|---|---|---|

| Operation | Uses lights to guide pickers to correct items | Automated conveyors transport items for picking |

| Accuracy | High accuracy, reduces picking errors | Moderate accuracy, depends on system integration |

| Speed | Fast for small to medium order volumes | Efficient for large, bulk order processing |

| Cost | Lower upfront cost, scalable | Higher initial investment, complex setup |

| Space Utilization | Compact footprint, ideal for dense storage | Requires more space for conveyor paths |

| Labor Dependency | Moderate, assists picker visually | Lower, conveyor automates item transport |

| Best Use Case | Order fulfillment in e-commerce, small parts | High-volume distribution centers, bulk goods |

Which is better?

Pick to light systems enhance order accuracy and speed by guiding operators visually, making them ideal for high SKU, low volume environments with complex orders. Conveyor-based picking systems optimize the flow of goods for high-volume, repetitive tasks, improving throughput and reducing manual transport in large warehouses. Choosing between them depends on operational scale, order complexity, and inventory characteristics.

Connection

Pick to light systems integrate seamlessly with conveyor-based picking systems to enhance order fulfillment efficiency by guiding operators to precise pick locations while enabling immediate placement onto conveyors. This synchronization reduces errors and speeds up throughput by automatically updating inventory and routing items along conveyor belts for sorting or shipping. Real-time data exchange between pick to light displays and conveyor controls ensures accurate tracking of picked items and smooth transitions through the distribution process.

Key Terms

Throughput

Conveyor-based picking systems achieve high throughput by enabling continuous movement of goods, reducing manual handling time and streamlining the sorting process. Pick to light systems optimize picking speed by guiding operators directly to items, minimizing errors and increasing accuracy in fast-paced environments. Explore the benefits of each system to determine the best fit for maximizing operational efficiency in your warehouse.

Order Accuracy

Conveyor-based picking systems enhance order accuracy by automating item transport, reducing human error during product selection. Pick to light systems improve accuracy through visual cues, enabling faster and more precise item identification for operators. Explore comprehensive insights on optimizing order accuracy with these technologies to boost your fulfillment efficiency.

Automation

Conveyor-based picking systems automate item transportation across warehouse zones, enhancing throughput with minimal manual handling, while pick to light systems optimize order accuracy by guiding operators through illuminated indicators at picking locations. Conveyor systems excel in high-volume distribution centers with continuous flow, whereas pick to light suits environments prioritizing precision in complex order assembly. Explore further insights on integrating automation to maximize warehouse efficiency.

Source and External Links

Combine Voice Picking and Zone Routing Conveyor Picking to Increase Productivity - Conveyor-based picking systems use pick-to-conveyor modules that combine voice-directed picking and zone routing to significantly boost picking speed, space efficiency, and labor reduction by minimizing operator walking and guiding picking through voice prompts in a person-to-goods method.

5 Warehouse Automated Picking Systems | Maveneer - Conveyor-based picking systems utilize conveyor belts to transport goods from storage to picking stations, forming part of automated warehouse solutions aimed at enhancing efficiency, reducing errors, and enabling scalable fulfillment.

E-COMMERCE ORDER PICKING CONVEYOR SYSTEM - YouTube - Conveyor-based picking systems can be fully automated, such as the NEPTEK system used in South Africa, which transports tote bins from mezzanine picking floors to packing stations, handling up to 6000 totes per hour and enabling high-throughput order fulfillment.

dowidth.com

dowidth.com