Predictive fleet maintenance leverages advanced data analytics and IoT sensors to anticipate vehicle failures and optimize repair schedules, reducing downtime and operational costs. Last-mile delivery focuses on efficient parcel movement from distribution centers to the final customer, emphasizing speed, route optimization, and real-time tracking to enhance customer satisfaction. Explore how integrating predictive maintenance with last-mile delivery can revolutionize logistics performance and reliability.

Why it is important

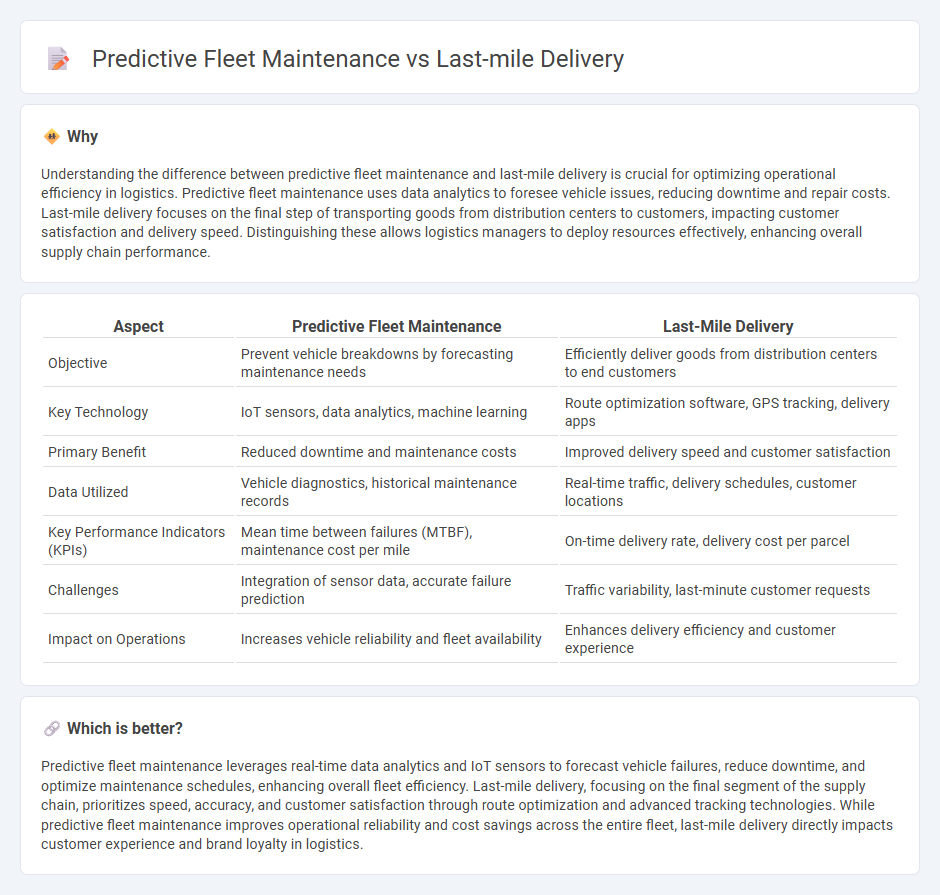

Understanding the difference between predictive fleet maintenance and last-mile delivery is crucial for optimizing operational efficiency in logistics. Predictive fleet maintenance uses data analytics to foresee vehicle issues, reducing downtime and repair costs. Last-mile delivery focuses on the final step of transporting goods from distribution centers to customers, impacting customer satisfaction and delivery speed. Distinguishing these allows logistics managers to deploy resources effectively, enhancing overall supply chain performance.

Comparison Table

| Aspect | Predictive Fleet Maintenance | Last-Mile Delivery |

|---|---|---|

| Objective | Prevent vehicle breakdowns by forecasting maintenance needs | Efficiently deliver goods from distribution centers to end customers |

| Key Technology | IoT sensors, data analytics, machine learning | Route optimization software, GPS tracking, delivery apps |

| Primary Benefit | Reduced downtime and maintenance costs | Improved delivery speed and customer satisfaction |

| Data Utilized | Vehicle diagnostics, historical maintenance records | Real-time traffic, delivery schedules, customer locations |

| Key Performance Indicators (KPIs) | Mean time between failures (MTBF), maintenance cost per mile | On-time delivery rate, delivery cost per parcel |

| Challenges | Integration of sensor data, accurate failure prediction | Traffic variability, last-minute customer requests |

| Impact on Operations | Increases vehicle reliability and fleet availability | Enhances delivery efficiency and customer experience |

Which is better?

Predictive fleet maintenance leverages real-time data analytics and IoT sensors to forecast vehicle failures, reduce downtime, and optimize maintenance schedules, enhancing overall fleet efficiency. Last-mile delivery, focusing on the final segment of the supply chain, prioritizes speed, accuracy, and customer satisfaction through route optimization and advanced tracking technologies. While predictive fleet maintenance improves operational reliability and cost savings across the entire fleet, last-mile delivery directly impacts customer experience and brand loyalty in logistics.

Connection

Predictive fleet maintenance leverages real-time data analytics and IoT sensors to anticipate vehicle failures, minimizing downtime and ensuring fleet reliability. This proactive approach enhances last-mile delivery efficiency by reducing delays caused by unexpected breakdowns, resulting in timely and cost-effective deliveries. Integrating predictive maintenance with last-mile logistics optimizes route planning and vehicle utilization, leading to improved customer satisfaction and operational sustainability.

Key Terms

**Last-mile delivery:**

Last-mile delivery focuses on optimizing the final step of the shipping process, ensuring timely and accurate package arrival directly to consumers. It leverages route optimization, real-time tracking, and customer communication to enhance delivery efficiency and satisfaction. Discover more about how innovative last-mile delivery solutions transform logistics performance.

Route Optimization

Last-mile delivery efficiency hinges on precise route optimization, reducing transit times and lowering operational costs by strategically planning delivery paths using real-time traffic data and customer availability. Predictive fleet maintenance complements route optimization by minimizing vehicle downtime through early detection of mechanical issues, ensuring a reliable fleet for seamless deliveries. Discover how integrating route optimization with predictive maintenance maximizes delivery efficiency and fleet longevity.

Delivery Time Window

Last-mile delivery emphasizes optimizing the delivery time window to increase customer satisfaction and reduce delays, crucial in urban logistics where precise timing impacts efficiency. Predictive fleet maintenance improves vehicle availability and reliability, indirectly supporting on-time deliveries by preventing unexpected breakdowns that could disrupt schedules. Explore how integrating these strategies can enhance operational performance and meet tight delivery time windows more effectively.

Source and External Links

Last mile delivery: solutions for your business - Last-mile delivery is the final leg of a product's journey from a local distribution center to the end customer, focusing on speedy, reliable, and cost-effective delivery by road or drop-off points, often integrating new technologies like autonomous robots and drones to improve service quality and consumer experience.

How it Works, Benefits, & How to Fulfill with Last-Mile Carriers - Last-mile delivery involves transporting packages from a fulfillment center directly to customers, being the most expensive part of retail logistics, and businesses often use technology and third-party logistics providers to optimize costs and enable real-time tracking for enhanced customer satisfaction.

Last-mile delivery: What it is and why it matters for retailers - The last-mile is the final and most costly stage of delivery, crucial for customer satisfaction and competitive advantage, where fast, direct deliveries improve convenience and increase business sales and operational efficiency through automation and new supply chain technologies.

dowidth.com

dowidth.com