Reshoring involves bringing manufacturing and supply chains back to a company's home country, while deglobalization refers to the broader decline of global trade and economic interdependence. Both trends impact employment, production costs, and national economic policies, with reshoring focusing on localizing supply chains to reduce reliance on distant markets. Explore how these shifts reshape the global economy and influence future business strategies.

Why it is important

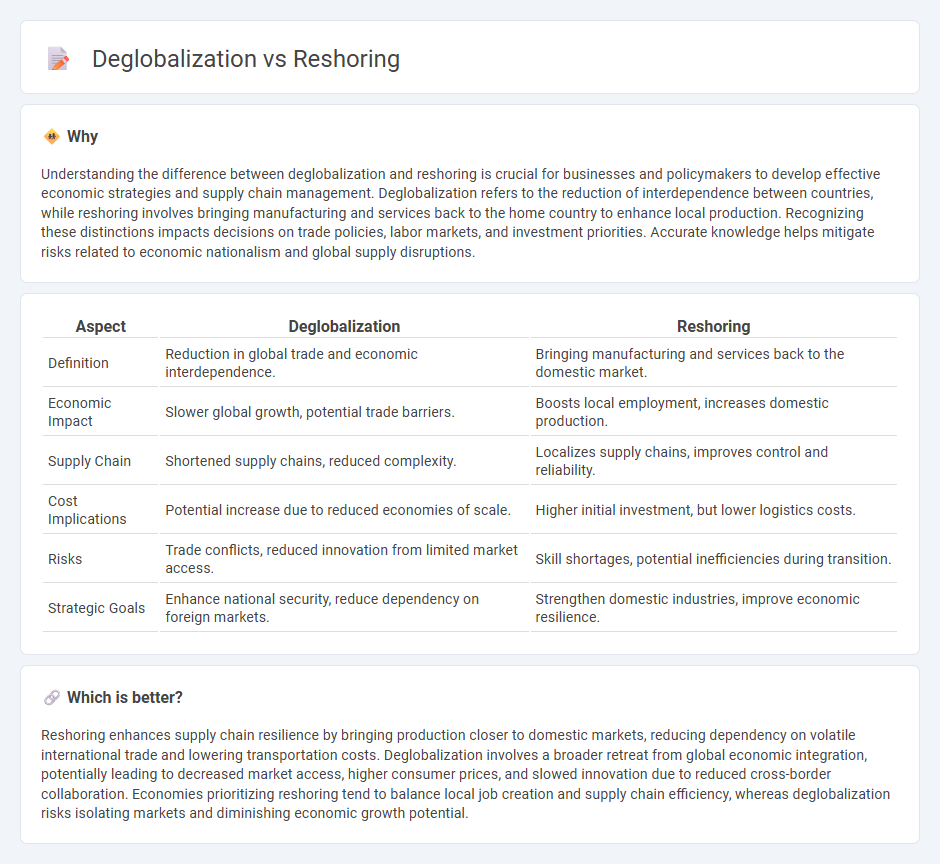

Understanding the difference between deglobalization and reshoring is crucial for businesses and policymakers to develop effective economic strategies and supply chain management. Deglobalization refers to the reduction of interdependence between countries, while reshoring involves bringing manufacturing and services back to the home country to enhance local production. Recognizing these distinctions impacts decisions on trade policies, labor markets, and investment priorities. Accurate knowledge helps mitigate risks related to economic nationalism and global supply disruptions.

Comparison Table

| Aspect | Deglobalization | Reshoring |

|---|---|---|

| Definition | Reduction in global trade and economic interdependence. | Bringing manufacturing and services back to the domestic market. |

| Economic Impact | Slower global growth, potential trade barriers. | Boosts local employment, increases domestic production. |

| Supply Chain | Shortened supply chains, reduced complexity. | Localizes supply chains, improves control and reliability. |

| Cost Implications | Potential increase due to reduced economies of scale. | Higher initial investment, but lower logistics costs. |

| Risks | Trade conflicts, reduced innovation from limited market access. | Skill shortages, potential inefficiencies during transition. |

| Strategic Goals | Enhance national security, reduce dependency on foreign markets. | Strengthen domestic industries, improve economic resilience. |

Which is better?

Reshoring enhances supply chain resilience by bringing production closer to domestic markets, reducing dependency on volatile international trade and lowering transportation costs. Deglobalization involves a broader retreat from global economic integration, potentially leading to decreased market access, higher consumer prices, and slowed innovation due to reduced cross-border collaboration. Economies prioritizing reshoring tend to balance local job creation and supply chain efficiency, whereas deglobalization risks isolating markets and diminishing economic growth potential.

Connection

Deglobalization and reshoring are interconnected as both involve shifting economic activities closer to domestic markets, reducing dependence on global supply chains. Deglobalization emphasizes protecting national industries and minimizing vulnerabilities exposed by global disruptions. Reshoring supports this shift by relocating production and manufacturing back to home countries, fostering economic resilience and job creation.

Key Terms

Supply Chain

Reshoring involves relocating manufacturing and supply chain operations back to a company's home country to enhance control, reduce risks, and respond faster to market demands, while deglobalization refers to the broader trend of decreasing global interdependence and trade. Supply chain strategies in reshoring prioritize local suppliers, shorter lead times, and improved resilience against global disruptions, whereas deglobalization may lead to fragmented supply chains and regional self-sufficiency. Explore how reshoring and deglobalization trends are reshaping global supply chain dynamics and what this means for businesses worldwide.

Trade Policy

Trade policy plays a crucial role in reshoring by incentivizing domestic production through tariffs, subsidies, and regulatory support, contrasting with deglobalization's broader retreat from international trade integration. Reshoring targets strategic supply chain resilience within global frameworks, while deglobalization emphasizes reducing dependence on global markets through protective trade barriers and localized economic blocs. Explore deeper insights on how evolving trade policies reshape global economic landscapes.

Manufacturing Repatriation

Manufacturing repatriation, a key aspect of reshoring, involves bringing production processes back to the home country to enhance supply chain resilience and reduce dependency on foreign suppliers. Deglobalization, a broader economic trend, encourages reduced global trade and investment flows, often driven by geopolitical tensions and rising protectionism, which can accelerate manufacturing repatriation decisions. Explore how reshoring impacts economic competitiveness and sustainability in the evolving global manufacturing landscape.

Source and External Links

Reshoring - Reshoring is the process of bringing manufacturing operations back from a foreign country to a business's home country to regain control over quality, lead times, and supply chain visibility.

What is Reshoring? Understanding Manufacturing ... - Reshoring is the relocation of production back to the country where the company is headquartered or from where their product is sold, after previously outsourcing overseas.

What is Reshoring? - Reshoring is the practice of bringing manufacturing and services back to the U.S. from overseas, aiming to strengthen the economy, reduce unemployment, and lower the total cost of products.

dowidth.com

dowidth.com