Fragmented supply chains involve dispersed, often uncoordinated production and distribution processes that can lead to inefficiencies and increased vulnerability to disruptions. Modular supply chains, by contrast, utilize standardized, interchangeable components that enhance flexibility, scalability, and resilience across multiple industries. Explore the advantages of modular supply chains in optimizing economic performance and mitigating global supply chain risks.

Why it is important

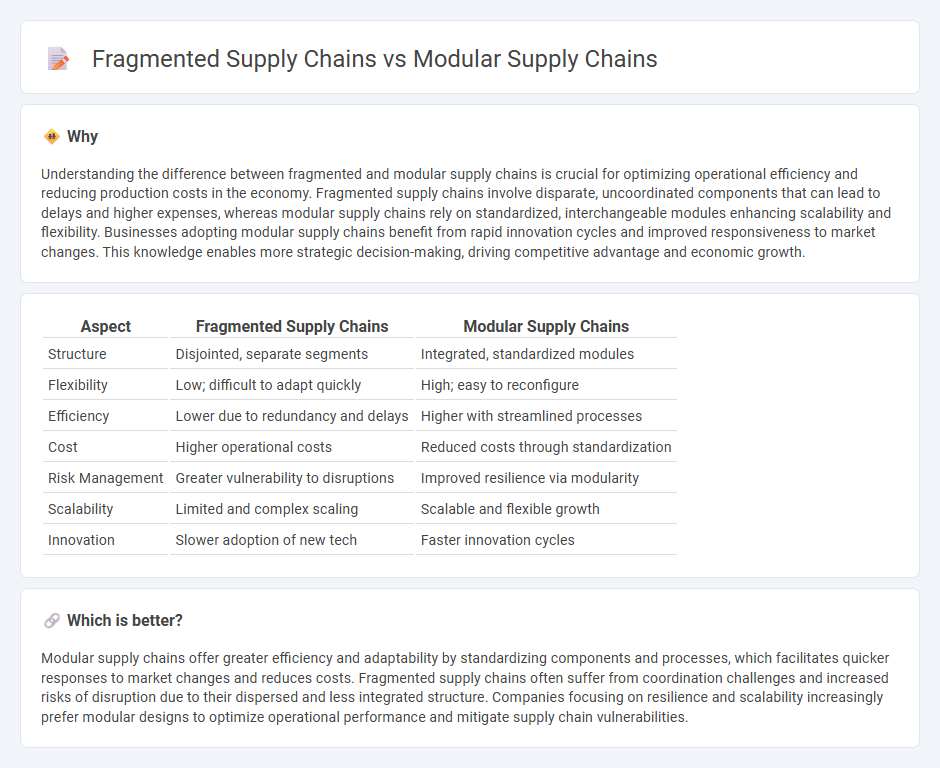

Understanding the difference between fragmented and modular supply chains is crucial for optimizing operational efficiency and reducing production costs in the economy. Fragmented supply chains involve disparate, uncoordinated components that can lead to delays and higher expenses, whereas modular supply chains rely on standardized, interchangeable modules enhancing scalability and flexibility. Businesses adopting modular supply chains benefit from rapid innovation cycles and improved responsiveness to market changes. This knowledge enables more strategic decision-making, driving competitive advantage and economic growth.

Comparison Table

| Aspect | Fragmented Supply Chains | Modular Supply Chains |

|---|---|---|

| Structure | Disjointed, separate segments | Integrated, standardized modules |

| Flexibility | Low; difficult to adapt quickly | High; easy to reconfigure |

| Efficiency | Lower due to redundancy and delays | Higher with streamlined processes |

| Cost | Higher operational costs | Reduced costs through standardization |

| Risk Management | Greater vulnerability to disruptions | Improved resilience via modularity |

| Scalability | Limited and complex scaling | Scalable and flexible growth |

| Innovation | Slower adoption of new tech | Faster innovation cycles |

Which is better?

Modular supply chains offer greater efficiency and adaptability by standardizing components and processes, which facilitates quicker responses to market changes and reduces costs. Fragmented supply chains often suffer from coordination challenges and increased risks of disruption due to their dispersed and less integrated structure. Companies focusing on resilience and scalability increasingly prefer modular designs to optimize operational performance and mitigate supply chain vulnerabilities.

Connection

Fragmented supply chains increase complexity by involving multiple independent suppliers and processes, which creates challenges in coordination and efficiency. Modular supply chains address this issue by organizing components into manageable, interchangeable modules, enhancing flexibility and reducing disruption risks. Integrating modular design within fragmented networks streamlines operations and improves overall economic resilience.

Key Terms

Integration

Modular supply chains emphasize high integration by standardizing components and processes, enabling seamless coordination and flexibility across different suppliers and production stages. Fragmented supply chains often suffer from poor integration, leading to inefficiencies, miscommunication, and delayed response times due to disparate systems and disconnected workflows. Explore our insights to understand how enhanced integration in modular supply chains drives resilience and operational excellence.

Coordination

Modular supply chains enhance coordination by integrating standardized components and processes, enabling seamless collaboration across suppliers, manufacturers, and distributors. Fragmented supply chains often struggle with misaligned communication and inconsistent data flow, leading to inefficiencies and delays. Explore how modular supply chain strategies can improve coordination and drive operational excellence.

Efficiency

Modular supply chains enhance efficiency by enabling standardized components and streamlined processes, reducing lead times and minimizing complexities. Fragmented supply chains often face inefficiencies due to lack of coordination and inconsistent workflows across multiple independent entities. Explore the benefits of modular supply chains to optimize operational performance and reduce costs.

Source and External Links

Modular Systems, Boosting Supply Chain Efficiency - Modular supply chains enhance efficiency by enabling flexibility, customer-specific product variations, resilience against disruptions through interchangeable modules, and redundancy strategies that reduce risk of failure in operations.

How Does Modularity Supports Resilient Supply Chains? - Modularity in supply chains supports resilience by enabling isolated changes in modules without cascade effects, harmonizing components to reduce variants, facilitating multi-sourcing, regional diversification, and buffering critical components efficiently.

Benefits and Applications of Modular Construction in Global Supply Chain Facilities - Modular construction improves supply chain infrastructure by enabling rapid expansion or modification of warehouses, cold storage, distribution hubs, and office modules, supporting scalable and adaptive operations in a fast-changing logistics environment.

dowidth.com

dowidth.com