Fragmented supply chains involve multiple independent suppliers spread across different regions, increasing complexity and vulnerability to disruptions. Localized supply chains focus on sourcing and manufacturing within a confined geographic area, enhancing control, reducing transportation costs, and improving responsiveness. Explore how businesses weigh these models to optimize efficiency and resilience in the evolving economic landscape.

Why it is important

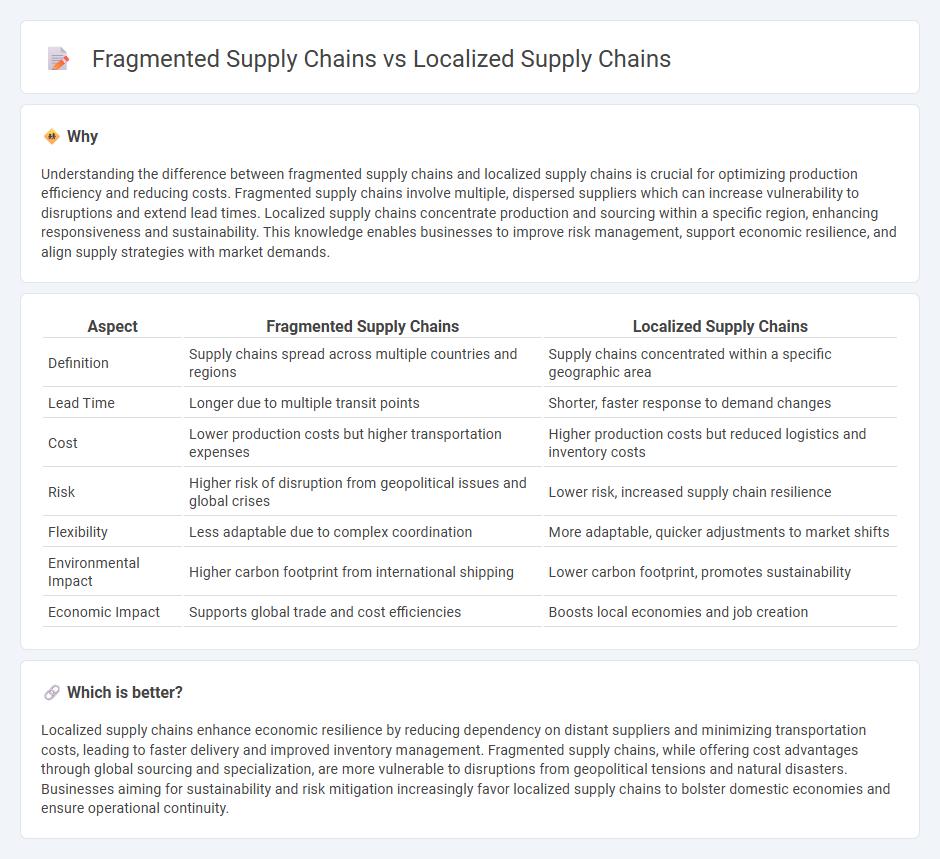

Understanding the difference between fragmented supply chains and localized supply chains is crucial for optimizing production efficiency and reducing costs. Fragmented supply chains involve multiple, dispersed suppliers which can increase vulnerability to disruptions and extend lead times. Localized supply chains concentrate production and sourcing within a specific region, enhancing responsiveness and sustainability. This knowledge enables businesses to improve risk management, support economic resilience, and align supply strategies with market demands.

Comparison Table

| Aspect | Fragmented Supply Chains | Localized Supply Chains |

|---|---|---|

| Definition | Supply chains spread across multiple countries and regions | Supply chains concentrated within a specific geographic area |

| Lead Time | Longer due to multiple transit points | Shorter, faster response to demand changes |

| Cost | Lower production costs but higher transportation expenses | Higher production costs but reduced logistics and inventory costs |

| Risk | Higher risk of disruption from geopolitical issues and global crises | Lower risk, increased supply chain resilience |

| Flexibility | Less adaptable due to complex coordination | More adaptable, quicker adjustments to market shifts |

| Environmental Impact | Higher carbon footprint from international shipping | Lower carbon footprint, promotes sustainability |

| Economic Impact | Supports global trade and cost efficiencies | Boosts local economies and job creation |

Which is better?

Localized supply chains enhance economic resilience by reducing dependency on distant suppliers and minimizing transportation costs, leading to faster delivery and improved inventory management. Fragmented supply chains, while offering cost advantages through global sourcing and specialization, are more vulnerable to disruptions from geopolitical tensions and natural disasters. Businesses aiming for sustainability and risk mitigation increasingly favor localized supply chains to bolster domestic economies and ensure operational continuity.

Connection

Fragmented supply chains increase risks of disruptions by relying on multiple dispersed suppliers, while localized supply chains reduce vulnerability through geographic proximity and streamlined logistics. Businesses integrate both models to balance cost efficiency and resilience, optimizing inventory management and delivery speed. Understanding the interplay between fragmentation and localization is critical for improving supply chain agility and economic stability.

Key Terms

Resilience

Localized supply chains enhance resilience by reducing dependency on distant suppliers and minimizing transportation risks, allowing for quicker adaptation to disruptions. Fragmented supply chains, while sometimes cost-effective, are vulnerable to interruptions caused by geopolitical tensions, natural disasters, or logistical bottlenecks due to their dispersed nature. Explore how businesses can strategically design supply chains for optimal resilience and efficiency.

Efficiency

Localized supply chains enhance efficiency by reducing transportation costs and lead times, enabling faster response to market demands and minimizing inventory holding costs. Fragmented supply chains often suffer from increased complexity, higher risks of delays, and difficulties in coordination, which can reduce overall operational efficiency. Explore more to understand how optimizing supply chain structures can drive competitive advantage and sustainability.

Risk Management

Localized supply chains minimize exposure to global disruptions by reducing transportation distances and dependency on multiple external suppliers, enhancing risk management through greater control and faster response times. Fragmented supply chains increase vulnerability to geopolitical instability, currency fluctuations, and regulatory changes, leading to potential delays and higher mitigation costs. Explore strategies and tools designed to optimize risk management in both localized and fragmented supply chain models.

Source and External Links

Localized Supply Chains - Climate - Sustainability Directory - Localized supply chains focus on regional self-reliance, characterized by geographic proximity, regional sourcing, shorter lead times, enhanced resilience, and community focus, providing benefits such as reduced carbon footprint, stronger local economies, and better supply chain transparency.

7 Steps to Building Localized Supply Chains - Localized supply chains concentrate operations within a limited area to reduce risks associated with globalization, emphasizing local market analysis, sourcing, and adapting supply chain strategy to the regional context for better responsiveness and resilience.

Effective Strategies for Localized Supply Chain Management in America - Supply chain localization meets growing consumer demand for locally sourced products by improving transparency, competitiveness, regulatory compliance, and sustainability while addressing challenges like higher production costs through technology and incentives.

dowidth.com

dowidth.com