Fragmented supply chains involve multiple disconnected stages and suppliers, leading to increased complexity and potential delays, whereas just-in-time (JIT) supply chains focus on minimizing inventory by synchronizing production with immediate demand. This contrast affects operational efficiency, risk management, and cost control across industries. Explore the key differences and strategic impacts of these supply chain models to optimize your economic decisions.

Why it is important

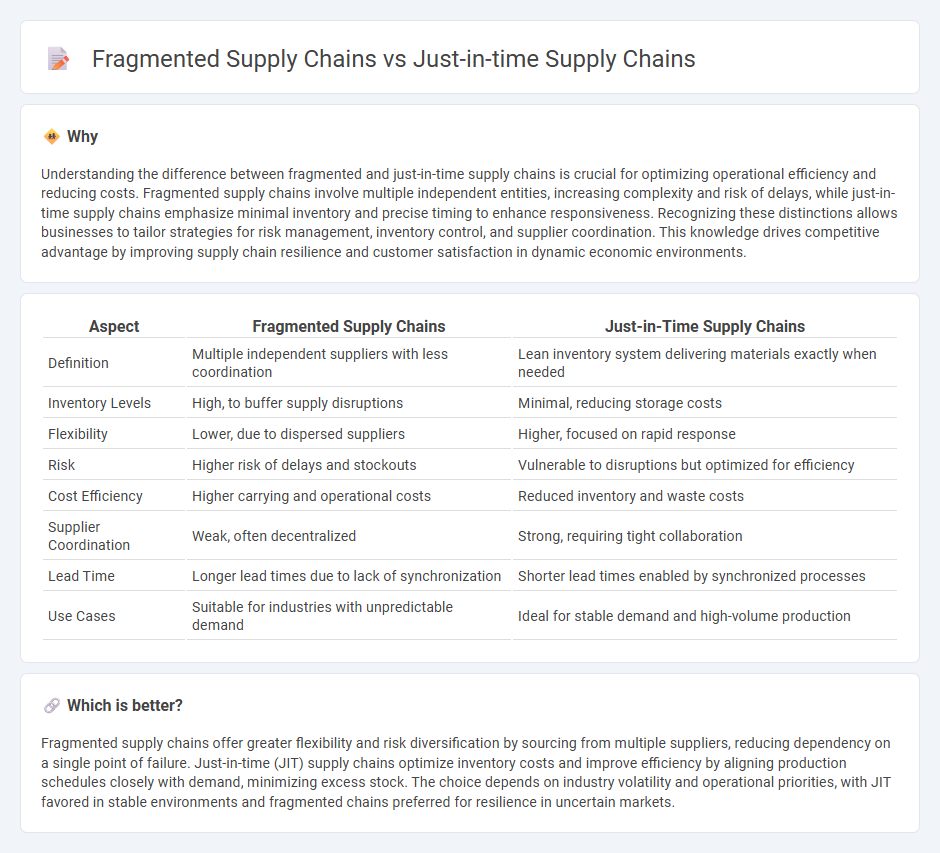

Understanding the difference between fragmented and just-in-time supply chains is crucial for optimizing operational efficiency and reducing costs. Fragmented supply chains involve multiple independent entities, increasing complexity and risk of delays, while just-in-time supply chains emphasize minimal inventory and precise timing to enhance responsiveness. Recognizing these distinctions allows businesses to tailor strategies for risk management, inventory control, and supplier coordination. This knowledge drives competitive advantage by improving supply chain resilience and customer satisfaction in dynamic economic environments.

Comparison Table

| Aspect | Fragmented Supply Chains | Just-in-Time Supply Chains |

|---|---|---|

| Definition | Multiple independent suppliers with less coordination | Lean inventory system delivering materials exactly when needed |

| Inventory Levels | High, to buffer supply disruptions | Minimal, reducing storage costs |

| Flexibility | Lower, due to dispersed suppliers | Higher, focused on rapid response |

| Risk | Higher risk of delays and stockouts | Vulnerable to disruptions but optimized for efficiency |

| Cost Efficiency | Higher carrying and operational costs | Reduced inventory and waste costs |

| Supplier Coordination | Weak, often decentralized | Strong, requiring tight collaboration |

| Lead Time | Longer lead times due to lack of synchronization | Shorter lead times enabled by synchronized processes |

| Use Cases | Suitable for industries with unpredictable demand | Ideal for stable demand and high-volume production |

Which is better?

Fragmented supply chains offer greater flexibility and risk diversification by sourcing from multiple suppliers, reducing dependency on a single point of failure. Just-in-time (JIT) supply chains optimize inventory costs and improve efficiency by aligning production schedules closely with demand, minimizing excess stock. The choice depends on industry volatility and operational priorities, with JIT favored in stable environments and fragmented chains preferred for resilience in uncertain markets.

Connection

Fragmented supply chains rely on multiple independent suppliers, increasing complexity and risk, while just-in-time supply chains depend on precise timing and minimal inventory to reduce costs. The interconnection lies in the vulnerability of just-in-time systems to disruptions caused by fragmentation, where delays or failures in one segment can halt the entire production process. Understanding this relationship is crucial for optimizing supply chain resilience and efficiency in a global economy.

Key Terms

Inventory Management

Just-in-time (JIT) supply chains minimize inventory levels by synchronizing production closely with demand, reducing holding costs and enhancing efficiency. Fragmented supply chains often maintain higher inventory buffers due to lack of coordination, leading to increased storage expenses and risk of obsolescence. Explore how optimizing inventory management strategies can drive cost savings and operational agility across supply chain models.

Lead Time

Just-in-time supply chains minimize lead time by synchronizing production schedules with demand, reducing inventory holding and accelerating product flow. Fragmented supply chains face longer lead times due to disconnected processes, inefficiencies, and inventory delays across multiple suppliers and stages. Explore detailed analyses and case studies to understand how optimizing lead time impacts supply chain performance.

Supplier Network

Just-in-time supply chains rely on a tightly integrated supplier network that emphasizes real-time communication, minimal inventory, and synchronized deliveries to reduce waste and increase efficiency. Fragmented supply chains consist of loosely connected suppliers with less coordination, often leading to higher inventory costs, delays, and supply disruptions. Explore the dynamics of supplier networks to understand how integration impacts supply chain resilience and performance.

Source and External Links

The State of Just-in-time Supply Chains - Just-in-time (JIT) supply chains streamline production by delivering raw materials only as needed to reduce inventory costs and increase efficiency, but they are vulnerable to disruptions like those caused by Covid-19, which exposed weaknesses in real-time supplier responsiveness and inventory reserves.

Just-in-Time (JIT): Agility and Efficiency in the Supply Chain - JIT is a lean manufacturing approach that aligns supply precisely with demand to minimize waste and storage costs while enhancing operational agility to quickly adapt to market changes and continuously improve efficiency and customer value.

What is Just in Time (JIT) Supply Chain Strategy? | GEP Glossary - JIT is a strategy focused on moving materials just before they are needed to reduce inventory and storage costs, but disruptions such as those from the Covid-19 pandemic have caused some companies to shift toward "just-in-case" supply chains that keep larger inventories to mitigate volatility risks.

dowidth.com

dowidth.com