Operational excellence mapping focuses on aligning business processes with strategic goals to enhance overall organizational performance and reduce inefficiencies. Process mapping visually represents individual workflows to identify bottlenecks and optimize task sequences, ensuring clarity and consistency in operations. Explore how integrating these methodologies can significantly improve your company's productivity and operational success.

Why it is important

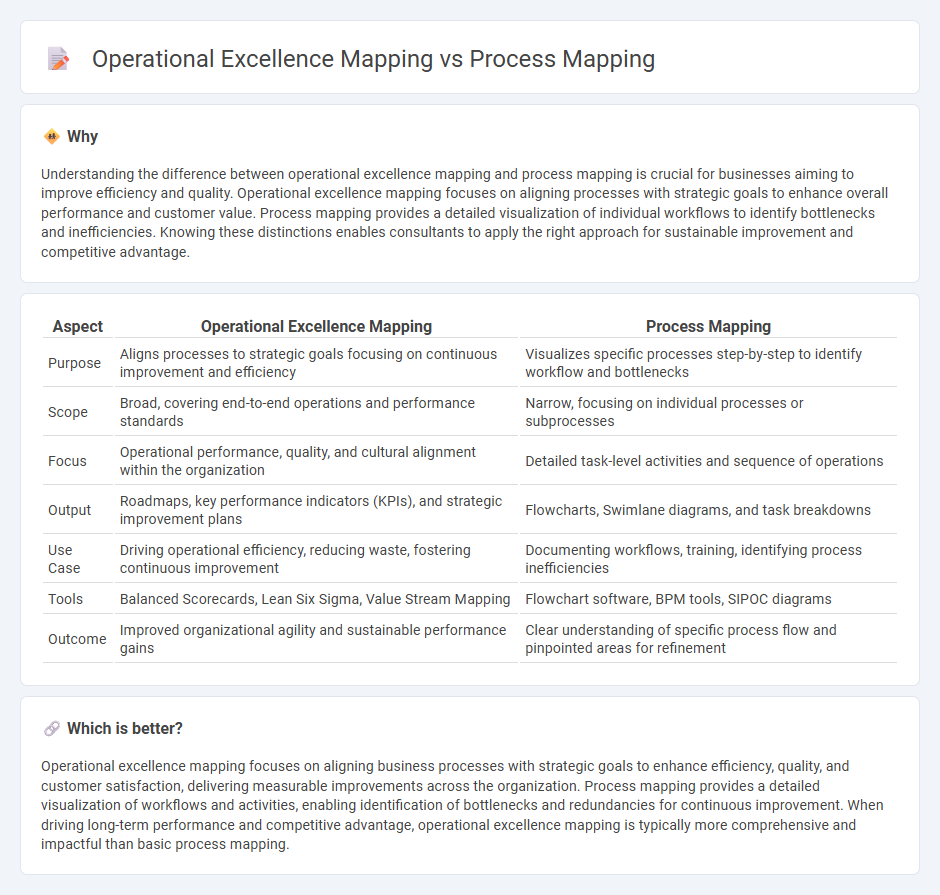

Understanding the difference between operational excellence mapping and process mapping is crucial for businesses aiming to improve efficiency and quality. Operational excellence mapping focuses on aligning processes with strategic goals to enhance overall performance and customer value. Process mapping provides a detailed visualization of individual workflows to identify bottlenecks and inefficiencies. Knowing these distinctions enables consultants to apply the right approach for sustainable improvement and competitive advantage.

Comparison Table

| Aspect | Operational Excellence Mapping | Process Mapping |

|---|---|---|

| Purpose | Aligns processes to strategic goals focusing on continuous improvement and efficiency | Visualizes specific processes step-by-step to identify workflow and bottlenecks |

| Scope | Broad, covering end-to-end operations and performance standards | Narrow, focusing on individual processes or subprocesses |

| Focus | Operational performance, quality, and cultural alignment within the organization | Detailed task-level activities and sequence of operations |

| Output | Roadmaps, key performance indicators (KPIs), and strategic improvement plans | Flowcharts, Swimlane diagrams, and task breakdowns |

| Use Case | Driving operational efficiency, reducing waste, fostering continuous improvement | Documenting workflows, training, identifying process inefficiencies |

| Tools | Balanced Scorecards, Lean Six Sigma, Value Stream Mapping | Flowchart software, BPM tools, SIPOC diagrams |

| Outcome | Improved organizational agility and sustainable performance gains | Clear understanding of specific process flow and pinpointed areas for refinement |

Which is better?

Operational excellence mapping focuses on aligning business processes with strategic goals to enhance efficiency, quality, and customer satisfaction, delivering measurable improvements across the organization. Process mapping provides a detailed visualization of workflows and activities, enabling identification of bottlenecks and redundancies for continuous improvement. When driving long-term performance and competitive advantage, operational excellence mapping is typically more comprehensive and impactful than basic process mapping.

Connection

Operational excellence mapping relies on process mapping to visually represent workflows and identify inefficiencies within business operations. Process mapping provides a detailed breakdown of each step, enabling consultants to analyze and optimize processes for improved performance and cost reduction. This connection ensures a strategic approach to achieving operational excellence through continuous process improvement and enhanced organizational alignment.

Key Terms

Workflow Visualization

Process mapping visualizes detailed workflows by illustrating each step, decision point, and sequence within a business process, enhancing clarity and communication. Operational excellence mapping integrates these workflows with strategic goals and performance metrics to drive continuous improvement and efficiency across the organization. Discover how aligning workflow visualization with operational excellence can transform your business outcomes.

Efficiency Optimization

Process mapping visually represents workflows to identify bottlenecks, redundancies, and inefficiencies, providing a detailed view of current operations for targeted improvements. Operational excellence mapping expands this approach by integrating strategic goals, continuous improvement methodologies, and performance metrics to drive efficiency optimization across all organizational levels. Explore how combining these mapping techniques can maximize operational performance and streamline business processes.

Value Stream Analysis

Process mapping visualizes individual workflows to identify inefficiencies and streamline tasks, while operational excellence mapping emphasizes Value Stream Analysis to optimize end-to-end processes, enhancing overall customer value by eliminating waste. Value Stream Analysis focuses on the flow of materials and information through all steps of a process, enabling organizations to identify bottlenecks and improve cycle time. Explore how combining these methodologies can drive continuous improvement and operational success.

Source and External Links

Process Mapping - Six Sigma Study Guide - Process mapping is a graphical tool that visually represents a process's inputs, actions, and outputs in order to help understand and improve the process by identifying areas like bottlenecks and inefficiencies.

What is Process Mapping? | IBM - Process mapping visually outlines the steps of a workflow, assigns task owners, and highlights areas for improvement to increase organizational efficiency and effectiveness.

6 Simple Process Mapping Examples to Organize Your Work - Motion - The process mapping creation involves defining the scope, assembling stakeholders, sequencing steps with clear symbols, and validating the map for continuous optimization.

dowidth.com

dowidth.com