Organizational design sprints focus on rapid, iterative redesign of company structures to enhance agility and responsiveness within weeks, while Lean Six Sigma emphasizes data-driven process improvement and waste reduction over a longer, more methodical timeframe. Companies aiming for swift transformation may prefer design sprints for their flexibility, whereas Lean Six Sigma suits those targeting measurable quality and efficiency gains rooted in statistical analysis. Explore more to determine which approach aligns best with your organization's strategic transformation goals.

Why it is important

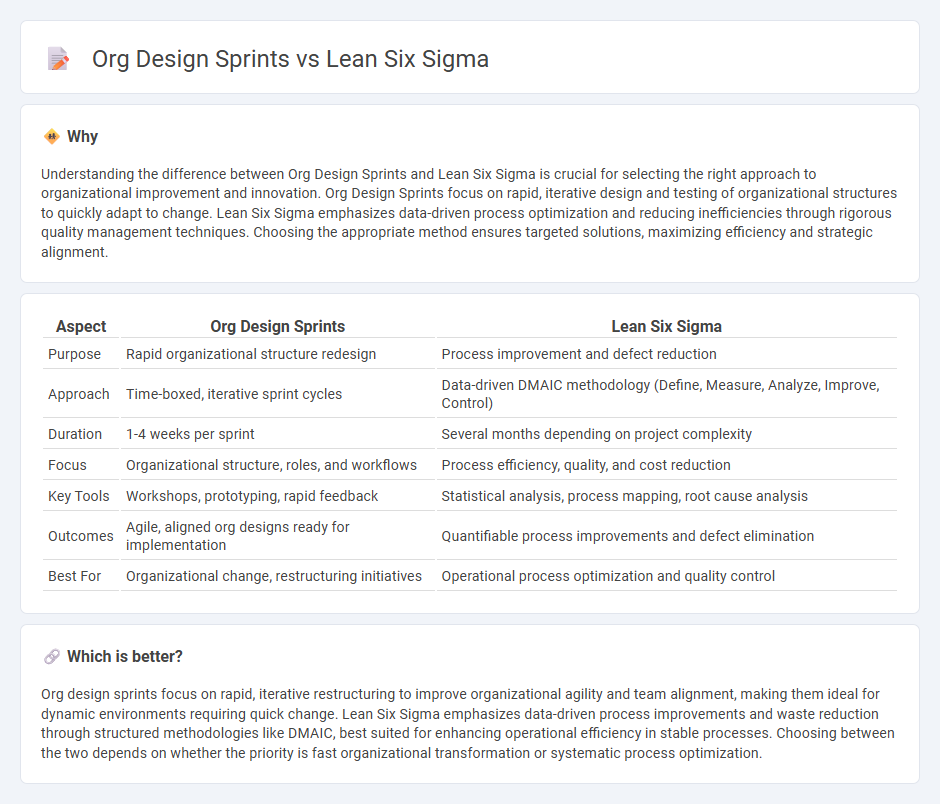

Understanding the difference between Org Design Sprints and Lean Six Sigma is crucial for selecting the right approach to organizational improvement and innovation. Org Design Sprints focus on rapid, iterative design and testing of organizational structures to quickly adapt to change. Lean Six Sigma emphasizes data-driven process optimization and reducing inefficiencies through rigorous quality management techniques. Choosing the appropriate method ensures targeted solutions, maximizing efficiency and strategic alignment.

Comparison Table

| Aspect | Org Design Sprints | Lean Six Sigma |

|---|---|---|

| Purpose | Rapid organizational structure redesign | Process improvement and defect reduction |

| Approach | Time-boxed, iterative sprint cycles | Data-driven DMAIC methodology (Define, Measure, Analyze, Improve, Control) |

| Duration | 1-4 weeks per sprint | Several months depending on project complexity |

| Focus | Organizational structure, roles, and workflows | Process efficiency, quality, and cost reduction |

| Key Tools | Workshops, prototyping, rapid feedback | Statistical analysis, process mapping, root cause analysis |

| Outcomes | Agile, aligned org designs ready for implementation | Quantifiable process improvements and defect elimination |

| Best For | Organizational change, restructuring initiatives | Operational process optimization and quality control |

Which is better?

Org design sprints focus on rapid, iterative restructuring to improve organizational agility and team alignment, making them ideal for dynamic environments requiring quick change. Lean Six Sigma emphasizes data-driven process improvements and waste reduction through structured methodologies like DMAIC, best suited for enhancing operational efficiency in stable processes. Choosing between the two depends on whether the priority is fast organizational transformation or systematic process optimization.

Connection

Org design sprints accelerate organizational transformation by rapidly prototyping and validating structural changes, ensuring alignment with business goals and stakeholder needs. Lean Six Sigma complements this process by providing data-driven methodologies to eliminate inefficiencies and enhance process quality within the redesigned organization. Combining these approaches drives agile, continuous improvement and optimized organizational performance.

Key Terms

Continuous Improvement

Lean Six Sigma emphasizes data-driven processes and reducing variability to enhance efficiency, optimizing workflows with tools like DMAIC and statistical analysis. Org design sprints prioritize rapid, iterative team collaboration and innovation to address organizational challenges and improve alignment and agility. Explore the unique benefits and applications of each method to transform your continuous improvement approach.

Process Mapping

Lean Six Sigma emphasizes detailed process mapping to eliminate process inefficiencies and reduce variation through data-driven analysis and DMAIC methodology. Org design sprints leverage rapid, collaborative workshops to redefine workflows and roles for organizational agility without extensive documentation. Explore how integrating Lean Six Sigma and org design sprints can optimize your process mapping efforts effectively.

Cross-functional Collaboration

Lean Six Sigma enhances cross-functional collaboration by streamlining processes through data-driven problem-solving and eliminating inefficiencies across departments. Organizational design sprints accelerate teamwork by rapidly testing and iterating structural changes, fostering adaptive environments for collaboration. Discover how integrating these methodologies can supercharge your team's synergy and performance.

Source and External Links

Lean Six Sigma - Lean Six Sigma is a combined process improvement methodology that uses Lean's focus on eliminating waste and Six Sigma's emphasis on reducing defects--applying the DMAIC framework (Define, Measure, Analyze, Improve, Control) to enhance performance and quality in products and services.

Lean Six Sigma Process Improvement - Lean Six Sigma is a project management and process improvement approach centered on customer needs, identifying and eliminating waste, measuring value streams, and involving stakeholders through structured phases to deliver high-quality, efficient outcomes.

Lean Six Sigma - White, Yellow, Green & Black Belt - Lean Six Sigma is a management methodology aimed at increasing quality, performance, and customer satisfaction at lower costs by systematically removing waste and optimizing processes, with certification levels (White, Yellow, Green, Black Belt) indicating expertise and project leadership capabilities.

dowidth.com

dowidth.com