Micro fulfillment centers optimize order processing by leveraging automation and proximity to customers, reducing delivery times and operational costs compared to traditional in-store fulfillment. In-store fulfillment relies on existing retail space and staff to pick and pack orders, often facing challenges such as inventory accuracy and limited storage capacity. Explore detailed comparisons to understand which fulfillment strategy aligns best with your business goals.

Why it is important

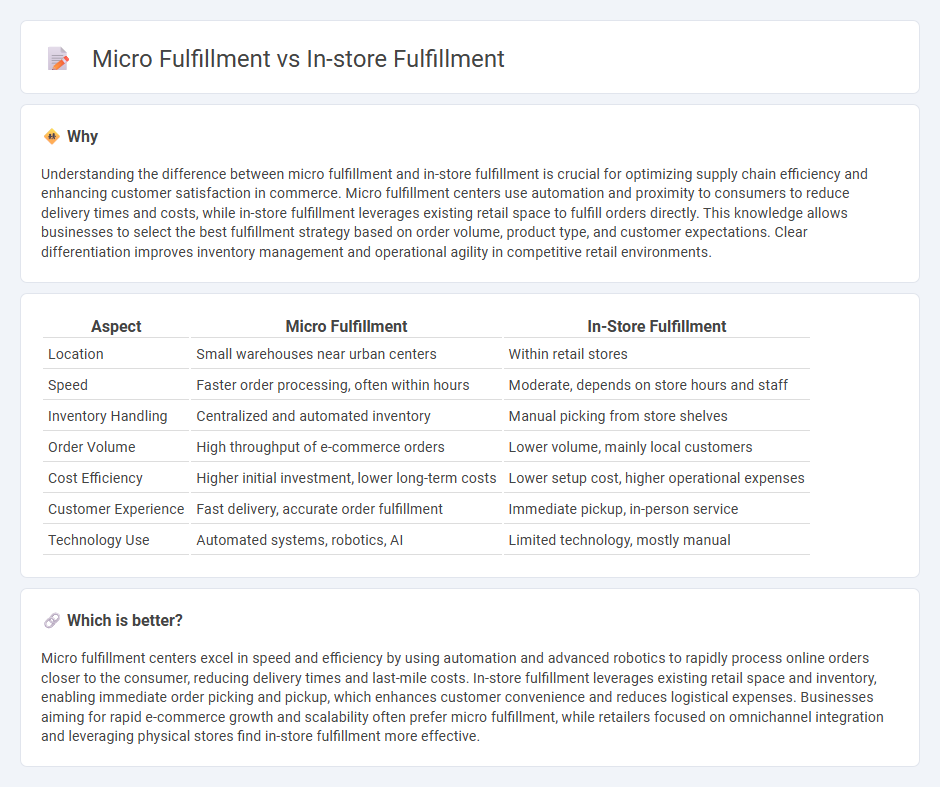

Understanding the difference between micro fulfillment and in-store fulfillment is crucial for optimizing supply chain efficiency and enhancing customer satisfaction in commerce. Micro fulfillment centers use automation and proximity to consumers to reduce delivery times and costs, while in-store fulfillment leverages existing retail space to fulfill orders directly. This knowledge allows businesses to select the best fulfillment strategy based on order volume, product type, and customer expectations. Clear differentiation improves inventory management and operational agility in competitive retail environments.

Comparison Table

| Aspect | Micro Fulfillment | In-Store Fulfillment |

|---|---|---|

| Location | Small warehouses near urban centers | Within retail stores |

| Speed | Faster order processing, often within hours | Moderate, depends on store hours and staff |

| Inventory Handling | Centralized and automated inventory | Manual picking from store shelves |

| Order Volume | High throughput of e-commerce orders | Lower volume, mainly local customers |

| Cost Efficiency | Higher initial investment, lower long-term costs | Lower setup cost, higher operational expenses |

| Customer Experience | Fast delivery, accurate order fulfillment | Immediate pickup, in-person service |

| Technology Use | Automated systems, robotics, AI | Limited technology, mostly manual |

Which is better?

Micro fulfillment centers excel in speed and efficiency by using automation and advanced robotics to rapidly process online orders closer to the consumer, reducing delivery times and last-mile costs. In-store fulfillment leverages existing retail space and inventory, enabling immediate order picking and pickup, which enhances customer convenience and reduces logistical expenses. Businesses aiming for rapid e-commerce growth and scalability often prefer micro fulfillment, while retailers focused on omnichannel integration and leveraging physical stores find in-store fulfillment more effective.

Connection

Micro fulfillment centers (MFCs) and in-store fulfillment are interconnected strategies designed to accelerate order processing and delivery within the commerce sector. MFCs leverage automated warehouses located near or inside retail stores, enabling rapid picking and packing of online orders, which complements in-store fulfillment by reducing the strain on traditional store staff and inventory. This synergy optimizes last-mile delivery efficiency, supports same-day shipping, and enhances customer satisfaction through faster order completion.

Key Terms

Inventory Management

In-store fulfillment leverages existing retail inventory, utilizing store shelves to pick and pack customer orders, which enhances inventory turnover and reduces storage costs. Micro fulfillment centers operate as small, automated warehouses near urban areas, optimizing inventory allocation for faster order processing and improved stock accuracy through advanced robotics and real-time data analytics. Explore the differences in inventory strategies to optimize your fulfillment operations effectively.

Order Processing

In-store fulfillment leverages existing retail locations to pick, pack, and ship customer orders directly from store inventory, enabling faster local delivery but often limited by store space and staff capacity. Micro fulfillment centers are small-scale, automated warehouses positioned near urban areas designed to handle high volumes of e-commerce orders with increased speed and accuracy, reducing last-mile delivery times and operational costs. Explore how each model impacts your supply chain efficiency and customer satisfaction.

Last-Mile Delivery

In-store fulfillment leverages existing retail locations to pick and ship orders, optimizing last-mile delivery by reducing transit distances and enabling faster same-day deliveries. Micro fulfillment utilizes automated, small-scale warehouses near urban centers to enhance order accuracy and expedite delivery times, significantly cutting down last-mile logistics costs. Explore more about how these innovative strategies revolutionize last-mile delivery efficiency.

Source and External Links

What is In Store Fulfillment & Why Is It Important For You? - In-store fulfillment is an omnichannel retail strategy that fulfills and ships online orders directly from physical stores instead of warehouses, reducing delivery times and shipping costs by leveraging store proximity to customers.

The Power of In-Store Fulfillment: Why it's Time to Gain a Competitive Edge - In-store fulfillment uses store inventory to fulfill online orders locally, enabling faster, more cost-effective delivery that meets growing consumer demand for same-day or faster shipping options.

Store fulfillment: Importance and 4 principles to utilize it in ... - Store fulfillment treats brick-and-mortar stores as micro-fulfillment centers, supporting diverse models like buy online pick up in store (BOPIS), curbside pickup, and ship-from-store to offer customers flexible, convenient shopping experiences.

dowidth.com

dowidth.com