Liquid cooling uses water or coolant to efficiently dissipate heat from computer components, offering high thermal conductivity and easy maintenance. Mineral oil cooling submerges hardware in non-conductive oil, providing uniform cooling and eliminating the need for fans, but it requires specialized setup and maintenance. Explore the key differences and benefits of each cooling method to determine the best solution for your system.

Why it is important

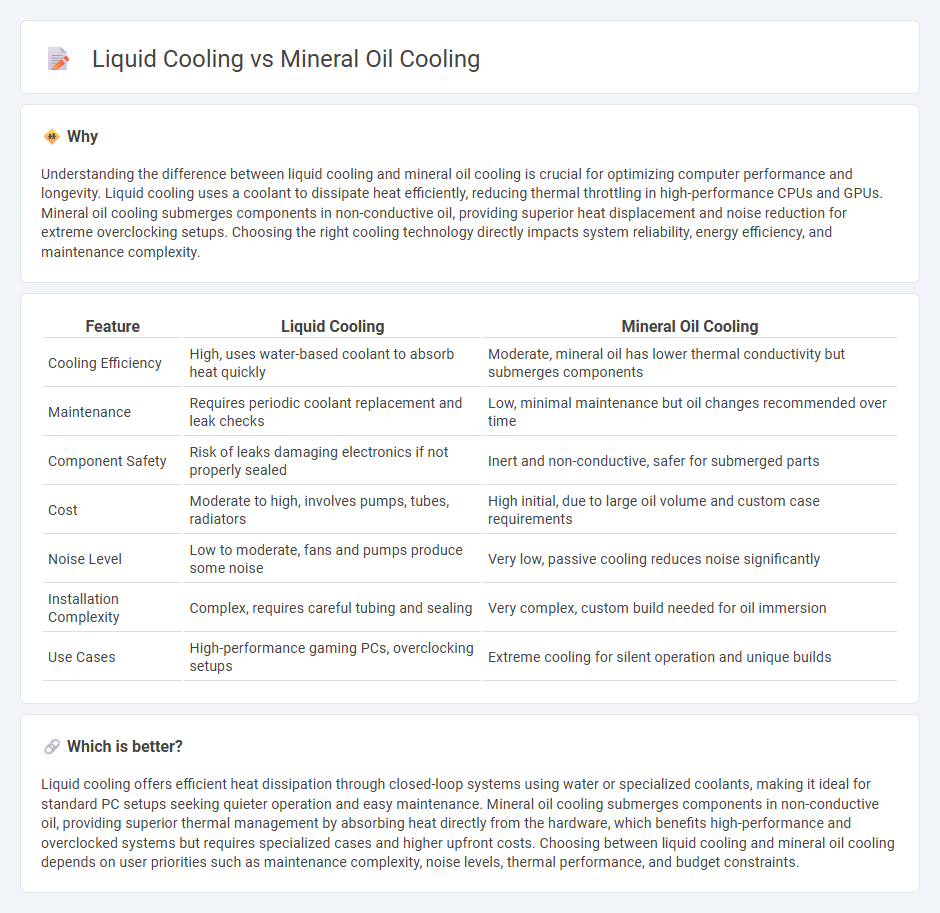

Understanding the difference between liquid cooling and mineral oil cooling is crucial for optimizing computer performance and longevity. Liquid cooling uses a coolant to dissipate heat efficiently, reducing thermal throttling in high-performance CPUs and GPUs. Mineral oil cooling submerges components in non-conductive oil, providing superior heat displacement and noise reduction for extreme overclocking setups. Choosing the right cooling technology directly impacts system reliability, energy efficiency, and maintenance complexity.

Comparison Table

| Feature | Liquid Cooling | Mineral Oil Cooling |

|---|---|---|

| Cooling Efficiency | High, uses water-based coolant to absorb heat quickly | Moderate, mineral oil has lower thermal conductivity but submerges components |

| Maintenance | Requires periodic coolant replacement and leak checks | Low, minimal maintenance but oil changes recommended over time |

| Component Safety | Risk of leaks damaging electronics if not properly sealed | Inert and non-conductive, safer for submerged parts |

| Cost | Moderate to high, involves pumps, tubes, radiators | High initial, due to large oil volume and custom case requirements |

| Noise Level | Low to moderate, fans and pumps produce some noise | Very low, passive cooling reduces noise significantly |

| Installation Complexity | Complex, requires careful tubing and sealing | Very complex, custom build needed for oil immersion |

| Use Cases | High-performance gaming PCs, overclocking setups | Extreme cooling for silent operation and unique builds |

Which is better?

Liquid cooling offers efficient heat dissipation through closed-loop systems using water or specialized coolants, making it ideal for standard PC setups seeking quieter operation and easy maintenance. Mineral oil cooling submerges components in non-conductive oil, providing superior thermal management by absorbing heat directly from the hardware, which benefits high-performance and overclocked systems but requires specialized cases and higher upfront costs. Choosing between liquid cooling and mineral oil cooling depends on user priorities such as maintenance complexity, noise levels, thermal performance, and budget constraints.

Connection

Liquid cooling and mineral oil cooling are advanced thermal management techniques used in high-performance computing systems to dissipate heat more efficiently than traditional air cooling. Both methods utilize fluids--liquid cooling typically employs water or coolant mixtures circulated through radiators, while mineral oil cooling involves submerging components directly in non-conductive oil to absorb heat. These cooling strategies enhance hardware performance and longevity by maintaining optimal operating temperatures and preventing thermal throttling in CPUs and GPUs.

Key Terms

Dielectric Fluid

Mineral oil cooling offers superior electrical insulation as a dielectric fluid, reducing the risk of short circuits while efficiently dissipating heat from electronic components. Liquid cooling systems often rely on water-based coolants that require additional anti-corrosion and dielectric additives to prevent electrical conductivity. Explore detailed comparisons and benefits of dielectric fluids in advanced cooling technologies to optimize system performance and reliability.

Heat Exchanger

Mineral oil cooling utilizes dielectric fluids to directly immerse electronic components, enhancing heat transfer through the fluid's ability to absorb heat and transfer it to a heat exchanger. Liquid cooling systems rely on water or coolant circulating through pipes and radiators, where the heat exchanger dissipates heat from the coolant to the ambient air efficiently. Explore detailed comparisons of heat exchanger designs and performance metrics to understand which cooling method suits your application best.

Immersion Cooling

Immersion cooling uses mineral oil or specialized dielectric fluids to submerge hardware, offering superior thermal conductivity and energy efficiency compared to traditional liquid cooling systems that rely on water or glycol mixtures. Mineral oil's non-conductive nature prevents electrical damage while enhancing heat dissipation, making it ideal for high-density data centers and cryptocurrency mining rigs. Explore the benefits and applications of immersion cooling to optimize your system's performance and reliability.

Source and External Links

Mineral Oil Cooling in PC Builds - Kingston Technology - Mineral oil is used to submerge PC components and acts as a highly effective, quiet, and long-lasting coolant by transferring heat away from parts and dissipating it into the surrounding air.

Mineral Oil Cooled PC - Puget Systems - A mineral oil PC build involves fully submerging standard computer components in clear, non-conductive mineral oil, which absorbs and transfers heat over five times better than air, often with the oil circulated through a radiator for additional cooling.

Why Oil-Cooled PCs Aren't Popular Anymore - How-To Geek - While mineral oil cooling is effective and visually striking, practical drawbacks include the need for regular oil maintenance, potential leaks, and slower heat dissipation compared to traditional methods, making it more of a novelty than a mainstream solution.

dowidth.com

dowidth.com