Smart shelves use IoT sensors and RFID technology to track inventory in real-time, enhancing stock accuracy and reducing out-of-stock situations in retail environments. Pick-to-light systems improve order fulfillment speed and accuracy by guiding employees with illuminated indicators at picking locations, streamlining warehouse and store operations. Explore the benefits and applications of smart shelves and pick-to-light systems in modern retail solutions.

Why it is important

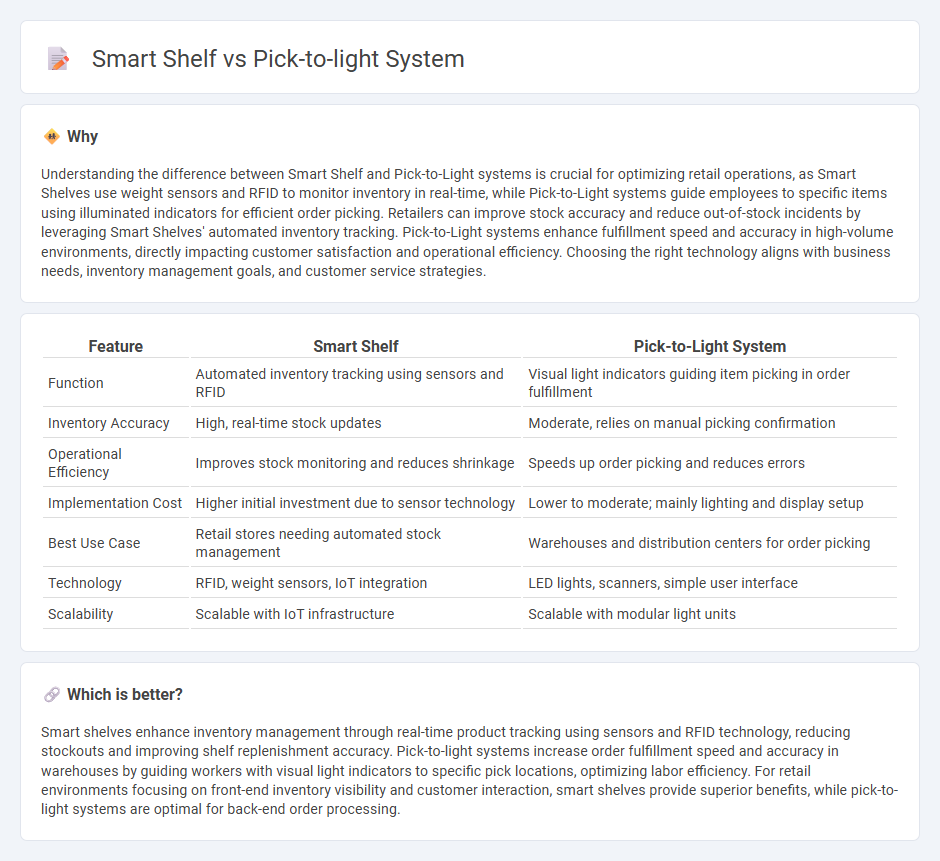

Understanding the difference between Smart Shelf and Pick-to-Light systems is crucial for optimizing retail operations, as Smart Shelves use weight sensors and RFID to monitor inventory in real-time, while Pick-to-Light systems guide employees to specific items using illuminated indicators for efficient order picking. Retailers can improve stock accuracy and reduce out-of-stock incidents by leveraging Smart Shelves' automated inventory tracking. Pick-to-Light systems enhance fulfillment speed and accuracy in high-volume environments, directly impacting customer satisfaction and operational efficiency. Choosing the right technology aligns with business needs, inventory management goals, and customer service strategies.

Comparison Table

| Feature | Smart Shelf | Pick-to-Light System |

|---|---|---|

| Function | Automated inventory tracking using sensors and RFID | Visual light indicators guiding item picking in order fulfillment |

| Inventory Accuracy | High, real-time stock updates | Moderate, relies on manual picking confirmation |

| Operational Efficiency | Improves stock monitoring and reduces shrinkage | Speeds up order picking and reduces errors |

| Implementation Cost | Higher initial investment due to sensor technology | Lower to moderate; mainly lighting and display setup |

| Best Use Case | Retail stores needing automated stock management | Warehouses and distribution centers for order picking |

| Technology | RFID, weight sensors, IoT integration | LED lights, scanners, simple user interface |

| Scalability | Scalable with IoT infrastructure | Scalable with modular light units |

Which is better?

Smart shelves enhance inventory management through real-time product tracking using sensors and RFID technology, reducing stockouts and improving shelf replenishment accuracy. Pick-to-light systems increase order fulfillment speed and accuracy in warehouses by guiding workers with visual light indicators to specific pick locations, optimizing labor efficiency. For retail environments focusing on front-end inventory visibility and customer interaction, smart shelves provide superior benefits, while pick-to-light systems are optimal for back-end order processing.

Connection

Smart shelves and Pick-to-light systems are integrated technologies enhancing retail inventory management and order fulfillment efficiency. Smart shelves use sensors and RFID tags to provide real-time inventory data, while Pick-to-light systems guide employees to the exact location of products with illuminated indicators, reducing errors and speeding up picking processes. Their connection streamlines stock accuracy, improves customer satisfaction, and optimizes supply chain operations in modern retail environments.

Key Terms

Order Fulfillment

Pick-to-light systems streamline order fulfillment by using illuminated displays to guide workers to the correct picking locations, boosting speed and accuracy in warehouses. Smart shelves enhance inventory management through embedded sensors that track stock levels in real-time, reducing picking errors and out-of-stock situations. Explore detailed comparisons to optimize your order fulfillment strategy effectively.

Inventory Tracking

Pick-to-light systems enhance inventory tracking by providing visual cues at the picking location, enabling faster and more accurate order fulfillment with real-time updates. Smart shelves use embedded sensors and RFID technology to monitor inventory levels continuously, alerting staff to stock discrepancies and preventing out-of-stock situations. Explore more on how these technologies optimize inventory management efficiency and accuracy.

Real-time Data

Pick-to-light systems provide real-time visual cues to streamline order picking with immediate feedback, enhancing accuracy and speed in inventory management. Smart shelves utilize integrated sensors and RFID technology to monitor stock levels continuously, offering precise real-time data on inventory status and product movement. Discover how leveraging real-time data through these technologies can optimize warehouse efficiency and boost operational performance.

Source and External Links

Pick-to-Light Systems: Elevating Order Accuracy - A Pick-to-Light system is a warehouse technology that uses light indicators and digital displays to guide workers to the correct product locations and quantities, improving picking speed and accuracy in order fulfillment.

Pick To Light system: What is it and how does it work? - The Pick To Light system integrates electronic compartment indicators and numerical displays controlled by warehouse management software to direct pickers to the exact item locations and quantities, updating inventory in real time and allowing simultaneous multi-order picking.

Pick-to-Light Applications - Pick-to-Light uses colored LED indicators to speed up and improve accuracy in manual picking, assembly, and kitting processes, with scalable devices that confirm picks via optical sensors detecting hand movements.

dowidth.com

dowidth.com