Assortment planning involves selecting the right mix of products to meet customer demand and maximize sales within a retail space, focusing on variety and relevance. Product allocation, on the other hand, deals with distributing available inventory across multiple locations based on sales forecasts and local preferences. Explore more to understand how these strategies drive retail efficiency and profitability.

Why it is important

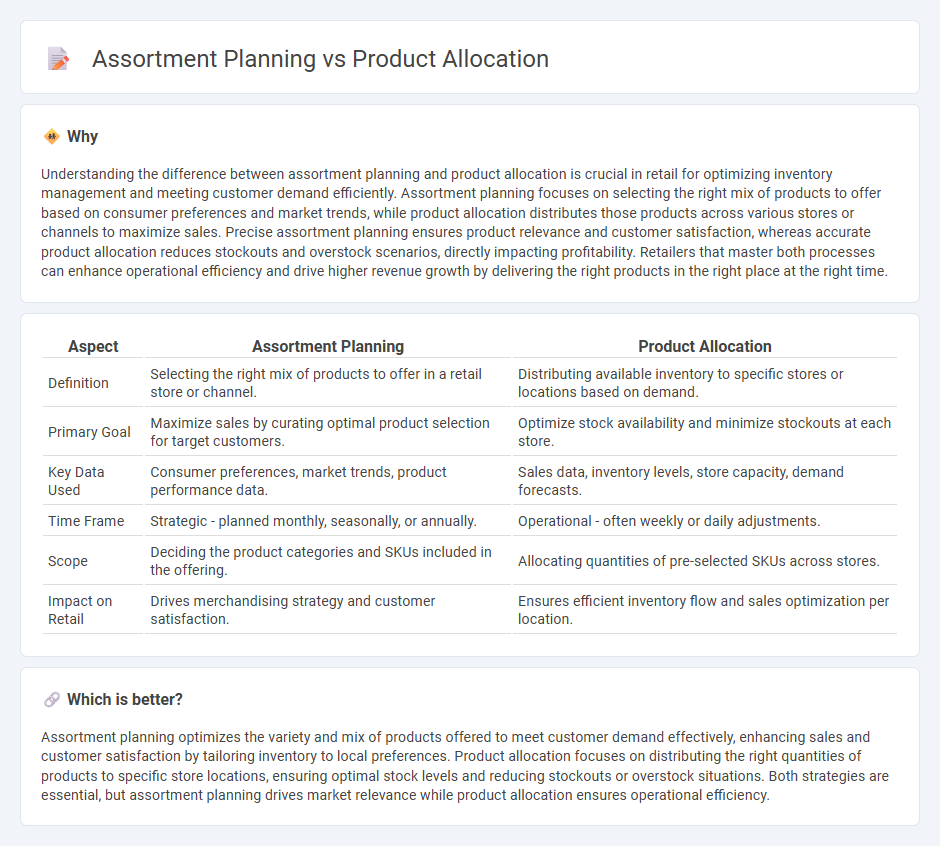

Understanding the difference between assortment planning and product allocation is crucial in retail for optimizing inventory management and meeting customer demand efficiently. Assortment planning focuses on selecting the right mix of products to offer based on consumer preferences and market trends, while product allocation distributes those products across various stores or channels to maximize sales. Precise assortment planning ensures product relevance and customer satisfaction, whereas accurate product allocation reduces stockouts and overstock scenarios, directly impacting profitability. Retailers that master both processes can enhance operational efficiency and drive higher revenue growth by delivering the right products in the right place at the right time.

Comparison Table

| Aspect | Assortment Planning | Product Allocation |

|---|---|---|

| Definition | Selecting the right mix of products to offer in a retail store or channel. | Distributing available inventory to specific stores or locations based on demand. |

| Primary Goal | Maximize sales by curating optimal product selection for target customers. | Optimize stock availability and minimize stockouts at each store. |

| Key Data Used | Consumer preferences, market trends, product performance data. | Sales data, inventory levels, store capacity, demand forecasts. |

| Time Frame | Strategic - planned monthly, seasonally, or annually. | Operational - often weekly or daily adjustments. |

| Scope | Deciding the product categories and SKUs included in the offering. | Allocating quantities of pre-selected SKUs across stores. |

| Impact on Retail | Drives merchandising strategy and customer satisfaction. | Ensures efficient inventory flow and sales optimization per location. |

Which is better?

Assortment planning optimizes the variety and mix of products offered to meet customer demand effectively, enhancing sales and customer satisfaction by tailoring inventory to local preferences. Product allocation focuses on distributing the right quantities of products to specific store locations, ensuring optimal stock levels and reducing stockouts or overstock situations. Both strategies are essential, but assortment planning drives market relevance while product allocation ensures operational efficiency.

Connection

Assortment planning involves selecting the right mix of products to meet customer demand, while product allocation ensures those products are distributed efficiently across retail locations. Effective coordination between these processes maximizes inventory turnover and enhances customer satisfaction by making the desired assortment available where it is most needed. Optimized assortment planning combined with precise product allocation leads to increased sales and reduced stockouts in retail environments.

Key Terms

Inventory Optimization

Product allocation optimizes inventory distribution by strategically assigning stock to different locations based on demand forecasts, minimizing stockouts and excess inventory. Assortment planning focuses on selecting the right mix of products to meet customer preferences and maximize sales, directly impacting inventory turnover rates. Explore how integrating these strategies enhances inventory optimization and drives retail success.

SKU Rationalization

Product allocation and assortment planning play crucial roles in SKU rationalization by optimizing inventory distribution and selection. While product allocation ensures the right quantity of SKUs reaches specific locations based on demand forecasts, assortment planning determines the optimal mix of SKUs to maximize sales and minimize excess inventory. Explore detailed strategies to enhance SKU rationalization and improve retail profitability.

Demand Forecasting

Product allocation optimizes inventory distribution based on demand forecasts to ensure stock availability across locations, while assortment planning uses demand insights to select the right mix of products tailored to customer preferences. Demand forecasting in product allocation emphasizes quantity allocation per store, leveraging sales velocity and historical data to minimize stockouts and overstocks. Explore more to understand how linking these strategies can enhance supply chain efficiency and boost sales performance.

Source and External Links

Understanding Product Allocation in Business Management - Product allocation is the strategic process of distributing, tracking, and managing inventory across sales channels to balance supply with customer demand, often using methods like equal, trend, or seasonal allocation to maximize sales and reduce costs.

What Is Product Allocation & How Can It Benefit Fulfillment? - Product allocation involves strategically distributing limited inventory across distribution networks with strategies such as equal, trend, and seasonal allocation to optimize product availability where demand is highest.

Product Allocation Defined: Methods & Best Practices - NetSuite - Product allocation is an inventory management approach that uses demand data and forecasting to allocate products either equally, by trends, or seasonally across distribution points to increase customer satisfaction and sales.

dowidth.com

dowidth.com