Drop shipping automation streamlines order processing by directly connecting retailers with suppliers, eliminating inventory storage and reducing logistical costs. Warehouse robotics enhances fulfillment efficiency through automated picking, packing, and sorting within centralized distribution centers, boosting speed and accuracy. Explore the pros and cons of drop shipping automation versus warehouse robotics to determine the best solution for your retail operations.

Why it is important

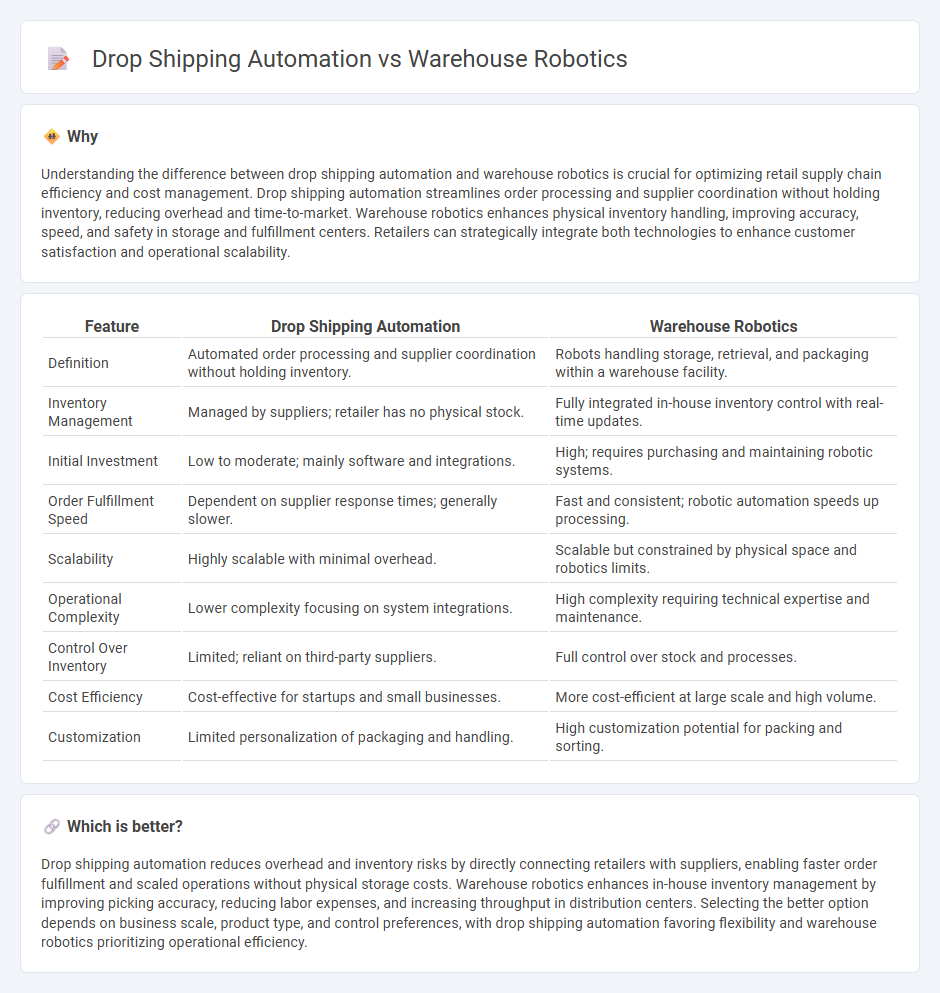

Understanding the difference between drop shipping automation and warehouse robotics is crucial for optimizing retail supply chain efficiency and cost management. Drop shipping automation streamlines order processing and supplier coordination without holding inventory, reducing overhead and time-to-market. Warehouse robotics enhances physical inventory handling, improving accuracy, speed, and safety in storage and fulfillment centers. Retailers can strategically integrate both technologies to enhance customer satisfaction and operational scalability.

Comparison Table

| Feature | Drop Shipping Automation | Warehouse Robotics |

|---|---|---|

| Definition | Automated order processing and supplier coordination without holding inventory. | Robots handling storage, retrieval, and packaging within a warehouse facility. |

| Inventory Management | Managed by suppliers; retailer has no physical stock. | Fully integrated in-house inventory control with real-time updates. |

| Initial Investment | Low to moderate; mainly software and integrations. | High; requires purchasing and maintaining robotic systems. |

| Order Fulfillment Speed | Dependent on supplier response times; generally slower. | Fast and consistent; robotic automation speeds up processing. |

| Scalability | Highly scalable with minimal overhead. | Scalable but constrained by physical space and robotics limits. |

| Operational Complexity | Lower complexity focusing on system integrations. | High complexity requiring technical expertise and maintenance. |

| Control Over Inventory | Limited; reliant on third-party suppliers. | Full control over stock and processes. |

| Cost Efficiency | Cost-effective for startups and small businesses. | More cost-efficient at large scale and high volume. |

| Customization | Limited personalization of packaging and handling. | High customization potential for packing and sorting. |

Which is better?

Drop shipping automation reduces overhead and inventory risks by directly connecting retailers with suppliers, enabling faster order fulfillment and scaled operations without physical storage costs. Warehouse robotics enhances in-house inventory management by improving picking accuracy, reducing labor expenses, and increasing throughput in distribution centers. Selecting the better option depends on business scale, product type, and control preferences, with drop shipping automation favoring flexibility and warehouse robotics prioritizing operational efficiency.

Connection

Drop shipping automation integrates order processing and supplier communication, enabling real-time inventory updates that align with warehouse robotics operations for efficient stock management. Warehouse robotics optimize picking, packing, and shipping tasks by using automated guided vehicles and robotic arms, which respond to drop shipped order data to enhance fulfillment speed. This synergy reduces human error, lowers labor costs, and accelerates delivery times in retail supply chains.

Key Terms

Fulfillment

Warehouse robotics significantly enhance fulfillment efficiency by automating inventory handling, picking, and packing processes, reducing errors and speeding up order processing. Drop shipping automation streamlines order transmission from retailers directly to suppliers, minimizing inventory costs but often extending delivery times and reducing control over packaging quality. Explore how both technologies transform fulfillment operations to optimize your supply chain strategy.

Inventory Management

Warehouse robotics streamline inventory management by automating tasks such as picking, sorting, and replenishment, resulting in increased accuracy and reduced labor costs. Drop shipping automation enhances inventory visibility and order processing without the need for physical stock, but relies heavily on supplier reliability and real-time data synchronization. Explore how each approach transforms inventory management to optimize supply chain efficiency.

Supply Chain Integration

Warehouse robotics enhances supply chain integration by automating inventory management, order fulfillment, and storage processes, leading to increased efficiency and accuracy within centralized distribution centers. Drop shipping automation streamlines order processing and supplier communication without holding inventory, enabling flexible and scalable supply chain operations but with reduced control over fulfillment speed and product quality. Explore how these technologies impact your supply chain integration strategy to optimize operational performance and customer satisfaction.

Source and External Links

Overview of Warehouse Robotics - Exotec - Warehouse robotics involves automated systems and robots that perform tasks like picking, packing, sorting, and transporting goods, enhancing efficiency, accuracy, and safety in warehouses by integrating with management systems and using data to optimize workflows.

15 Types of Warehouse Robotics For Optimal Efficiency - Modula USA - Warehouse robotics encompasses diverse machines that store, retrieve, and transport inventory, with best practices including detailed planning, integration with warehouse management systems, and training staff to operate robotic equipment for maximum efficiency and reduced human error.

What Is Warehouse Robotics? The Ultimate Guide for 2025 - NetSuite - A warehouse robot is an autonomous machine designed to replace or augment human labor in warehouse environments, performing repetitive and dangerous tasks to increase productivity, safety, and operational scalability while working alongside intelligent software systems.

dowidth.com

dowidth.com