Smart shelves use weight sensors and RFID technology to monitor inventory in real time, enhancing product availability and reducing shrinkage in retail stores. Out-of-stock detection systems employ image recognition and AI analytics to identify empty shelves quickly, improving restocking efficiency and customer satisfaction. Discover how integrating these technologies can revolutionize retail inventory management and boost sales performance.

Why it is important

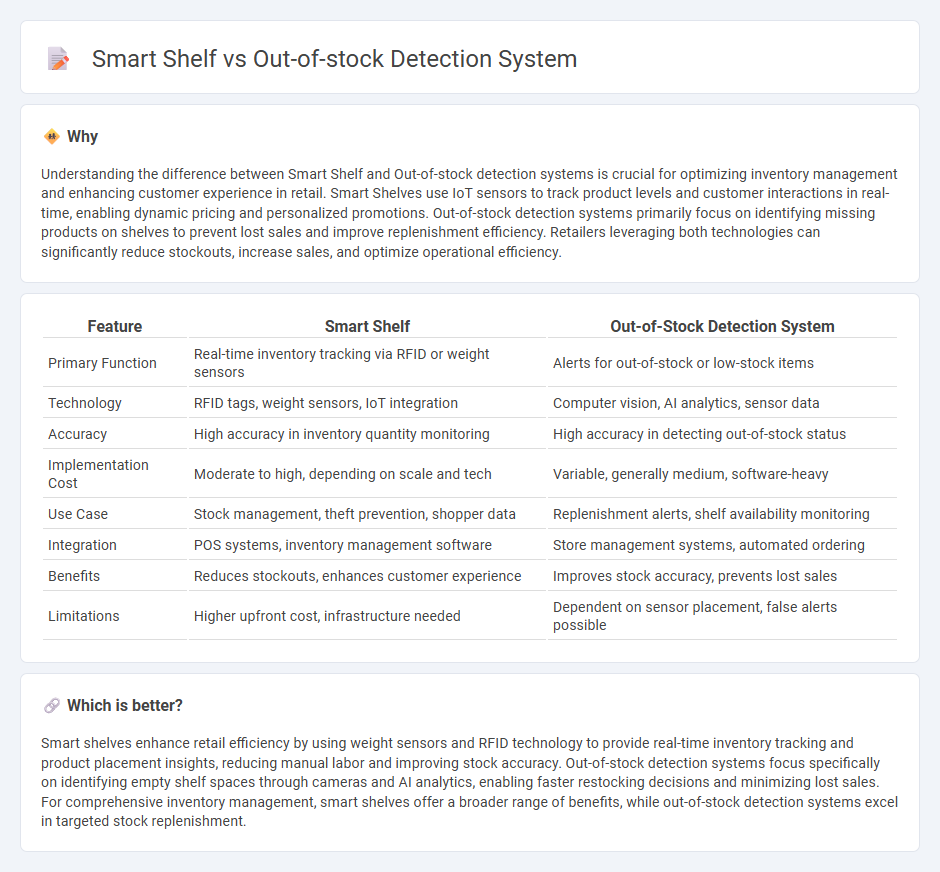

Understanding the difference between Smart Shelf and Out-of-stock detection systems is crucial for optimizing inventory management and enhancing customer experience in retail. Smart Shelves use IoT sensors to track product levels and customer interactions in real-time, enabling dynamic pricing and personalized promotions. Out-of-stock detection systems primarily focus on identifying missing products on shelves to prevent lost sales and improve replenishment efficiency. Retailers leveraging both technologies can significantly reduce stockouts, increase sales, and optimize operational efficiency.

Comparison Table

| Feature | Smart Shelf | Out-of-Stock Detection System |

|---|---|---|

| Primary Function | Real-time inventory tracking via RFID or weight sensors | Alerts for out-of-stock or low-stock items |

| Technology | RFID tags, weight sensors, IoT integration | Computer vision, AI analytics, sensor data |

| Accuracy | High accuracy in inventory quantity monitoring | High accuracy in detecting out-of-stock status |

| Implementation Cost | Moderate to high, depending on scale and tech | Variable, generally medium, software-heavy |

| Use Case | Stock management, theft prevention, shopper data | Replenishment alerts, shelf availability monitoring |

| Integration | POS systems, inventory management software | Store management systems, automated ordering |

| Benefits | Reduces stockouts, enhances customer experience | Improves stock accuracy, prevents lost sales |

| Limitations | Higher upfront cost, infrastructure needed | Dependent on sensor placement, false alerts possible |

Which is better?

Smart shelves enhance retail efficiency by using weight sensors and RFID technology to provide real-time inventory tracking and product placement insights, reducing manual labor and improving stock accuracy. Out-of-stock detection systems focus specifically on identifying empty shelf spaces through cameras and AI analytics, enabling faster restocking decisions and minimizing lost sales. For comprehensive inventory management, smart shelves offer a broader range of benefits, while out-of-stock detection systems excel in targeted stock replenishment.

Connection

Smart shelves use RFID and weight sensors to monitor product inventory in real time, enabling accurate out-of-stock detection. These systems trigger automatic alerts when stock levels fall below predefined thresholds, ensuring timely replenishment and preventing lost sales. Integration of smart shelf technology with out-of-stock detection enhances inventory accuracy and optimizes retail shelf management.

Key Terms

**Out-of-stock detection system:**

Out-of-stock detection systems utilize real-time sensors and AI algorithms to monitor inventory levels accurately, minimizing stockouts and improving customer satisfaction. These systems integrate with POS data and supply chain management, enabling automated replenishment and precise demand forecasting. Discover how out-of-stock detection technology can optimize inventory control and boost retail efficiency.

Inventory monitoring

Out-of-stock detection systems use sensors and real-time data analytics to immediately identify product shortages, minimizing sales loss and improving replenishment speed. Smart shelves integrate weight sensors and RFID technology, providing continuous inventory visibility and enhancing stock accuracy across retail environments. Explore comprehensive comparisons to optimize your inventory monitoring strategy effectively.

Real-time alerts

Out-of-stock detection systems utilize sensors and RFID technology to provide real-time alerts when inventory levels drop below a predefined threshold, ensuring timely restocking and preventing lost sales. Smart shelves integrate weight sensors and computer vision to offer continuous monitoring and automated alerts, optimizing inventory accuracy and enhancing customer experience. Explore the differences and benefits of these technologies to improve your retail operations with real-time stock management.

Source and External Links

Combatting Out of Stock Products: Automated Email Notifications - AI-powered systems can monitor inventory levels in real time, detect out-of-stock items instantly, and send personalized email notifications to customers, improving transparency and timely restocking.

Retail Image Recognition for Out-of-Stock Detection - ParallelDots - Image recognition technology scans store shelves in real time to identify product availability and out-of-stock conditions, reducing the reliance on manual audits and enabling proactive replenishment.

Prevent Product Voids and Out-of-Stocks - FORM - With a single photo, AI image recognition identifies out-of-stocks and voids on shelves and displays instantly, providing actionable insights to optimize supply chains and prevent lost sales through real-time reporting.

dowidth.com

dowidth.com