Retail operations increasingly rely on microfulfillment centers and automated distribution centers to enhance efficiency and speed. Microfulfillment centers are compact facilities situated close to urban areas, enabling rapid last-mile delivery with advanced robotics tailored for small-scale order processing. Explore the differences, benefits, and applications of these fulfillment strategies to optimize your retail supply chain.

Why it is important

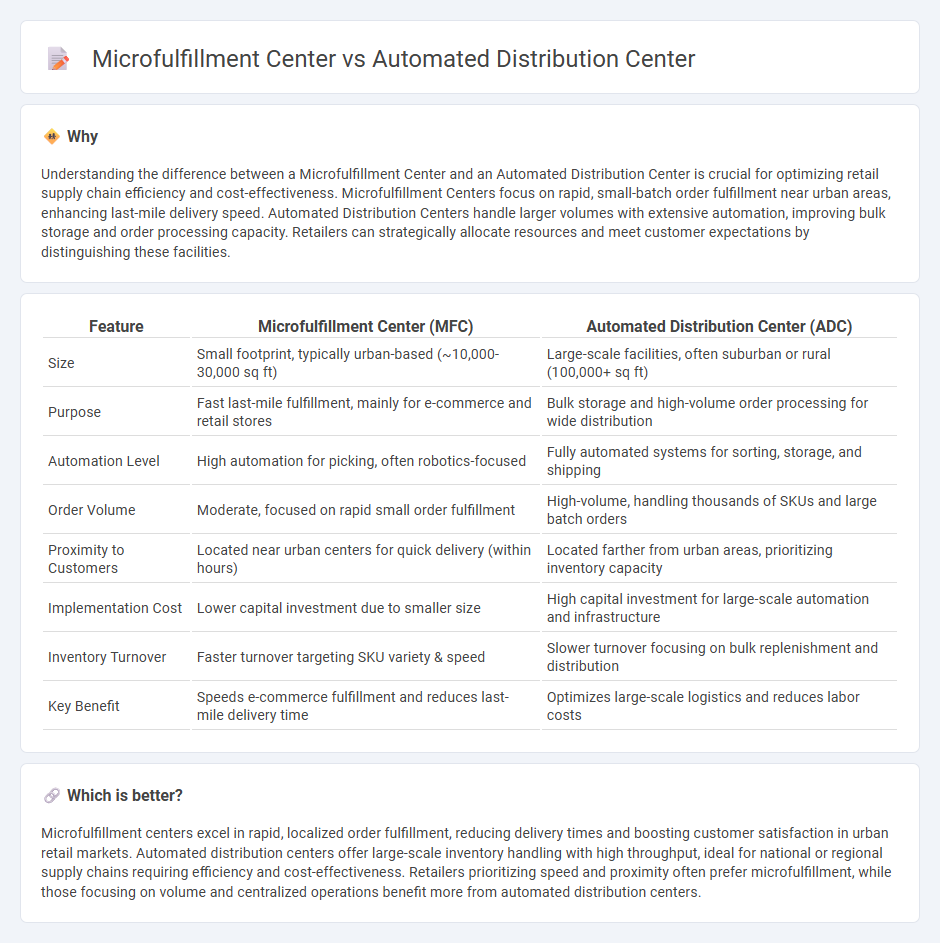

Understanding the difference between a Microfulfillment Center and an Automated Distribution Center is crucial for optimizing retail supply chain efficiency and cost-effectiveness. Microfulfillment Centers focus on rapid, small-batch order fulfillment near urban areas, enhancing last-mile delivery speed. Automated Distribution Centers handle larger volumes with extensive automation, improving bulk storage and order processing capacity. Retailers can strategically allocate resources and meet customer expectations by distinguishing these facilities.

Comparison Table

| Feature | Microfulfillment Center (MFC) | Automated Distribution Center (ADC) |

|---|---|---|

| Size | Small footprint, typically urban-based (~10,000-30,000 sq ft) | Large-scale facilities, often suburban or rural (100,000+ sq ft) |

| Purpose | Fast last-mile fulfillment, mainly for e-commerce and retail stores | Bulk storage and high-volume order processing for wide distribution |

| Automation Level | High automation for picking, often robotics-focused | Fully automated systems for sorting, storage, and shipping |

| Order Volume | Moderate, focused on rapid small order fulfillment | High-volume, handling thousands of SKUs and large batch orders |

| Proximity to Customers | Located near urban centers for quick delivery (within hours) | Located farther from urban areas, prioritizing inventory capacity |

| Implementation Cost | Lower capital investment due to smaller size | High capital investment for large-scale automation and infrastructure |

| Inventory Turnover | Faster turnover targeting SKU variety & speed | Slower turnover focusing on bulk replenishment and distribution |

| Key Benefit | Speeds e-commerce fulfillment and reduces last-mile delivery time | Optimizes large-scale logistics and reduces labor costs |

Which is better?

Microfulfillment centers excel in rapid, localized order fulfillment, reducing delivery times and boosting customer satisfaction in urban retail markets. Automated distribution centers offer large-scale inventory handling with high throughput, ideal for national or regional supply chains requiring efficiency and cost-effectiveness. Retailers prioritizing speed and proximity often prefer microfulfillment, while those focusing on volume and centralized operations benefit more from automated distribution centers.

Connection

Microfulfillment centers utilize automation technologies similar to those in automated distribution centers to optimize order fulfillment speed and accuracy in retail supply chains. Both centers employ robotics, AI-driven inventory management, and real-time data analytics to reduce labor costs and enhance delivery efficiency. This integration supports omnichannel retail strategies by enabling faster last-mile delivery and streamlined inventory replenishment.

Key Terms

Scale of Operations

Automated distribution centers typically handle large-scale operations with extensive storage capacity and high throughput rates, making them ideal for national or regional supply chains. Microfulfillment centers prioritize rapid last-mile delivery with smaller footprints, optimizing urban or densely populated market demands by leveraging automation within confined spaces. Explore the strategic advantages of each to determine the best fit for your supply chain needs.

Proximity to Customers

Automated distribution centers (ADCs) are typically located in large, centralized warehouses designed to handle high-volume inventory and long-distance shipping, often resulting in longer delivery times. In contrast, microfulfillment centers are strategically placed within urban or suburban areas, significantly reducing the distance to customers and enabling faster order fulfillment. Explore how choosing the right fulfillment model can enhance delivery speed and customer satisfaction.

Technology Integration

Automated distribution centers leverage advanced robotics, conveyor systems, and warehouse management software to optimize large-scale inventory handling and order fulfillment. Microfulfillment centers utilize compact automated solutions such as robotic picking and AI-driven inventory management tailored for rapid delivery in urban environments. Explore the latest technology trends shaping the future of distribution and microfulfillment centers to enhance efficiency and customer satisfaction.

Source and External Links

Distribution Center Automation Explained - DCKAP - Automated distribution centers use technology like robotic arms and warehouse management systems to streamline warehouse operations, reduce human labor costs, and improve ROI and efficiency by automating manual and repetitive tasks after careful workflow assessment and technology selection based on scalability and integration capability.

Automated Warehouses | Types and Benefits - AutoStore - Automated warehouses employ robots that autonomously retrieve and transport merchandise for picking and packing, integrating warehouse management systems to coordinate logistics flows such as receiving, storage, and shipping, helping reduce manual labor, errors, costs, and workplace hazards.

5 companies with automated warehouses: examples and benefits - Companies like British Sugar have implemented automated warehouses featuring automated pallet shuttles and stacker cranes, enhancing speed, capacity, safety, and operational flexibility for high-volume product handling in complex environments like temperature-controlled storage.

dowidth.com

dowidth.com