Modular construction offers rapid assembly with factory-built sections, reducing on-site labor and minimizing construction waste. Steel frame construction provides exceptional strength, durability, and design flexibility, making it ideal for large-scale or high-rise buildings. Explore the key differences and benefits of modular and steel frame construction to determine the best fit for your real estate project.

Why it is important

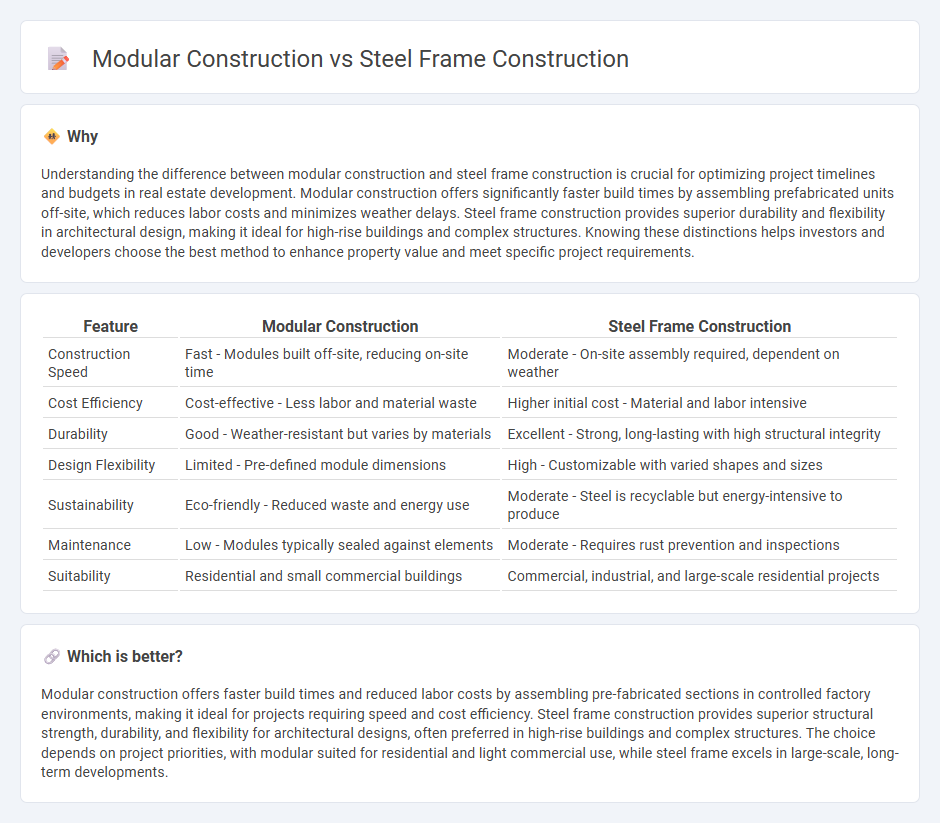

Understanding the difference between modular construction and steel frame construction is crucial for optimizing project timelines and budgets in real estate development. Modular construction offers significantly faster build times by assembling prefabricated units off-site, which reduces labor costs and minimizes weather delays. Steel frame construction provides superior durability and flexibility in architectural design, making it ideal for high-rise buildings and complex structures. Knowing these distinctions helps investors and developers choose the best method to enhance property value and meet specific project requirements.

Comparison Table

| Feature | Modular Construction | Steel Frame Construction |

|---|---|---|

| Construction Speed | Fast - Modules built off-site, reducing on-site time | Moderate - On-site assembly required, dependent on weather |

| Cost Efficiency | Cost-effective - Less labor and material waste | Higher initial cost - Material and labor intensive |

| Durability | Good - Weather-resistant but varies by materials | Excellent - Strong, long-lasting with high structural integrity |

| Design Flexibility | Limited - Pre-defined module dimensions | High - Customizable with varied shapes and sizes |

| Sustainability | Eco-friendly - Reduced waste and energy use | Moderate - Steel is recyclable but energy-intensive to produce |

| Maintenance | Low - Modules typically sealed against elements | Moderate - Requires rust prevention and inspections |

| Suitability | Residential and small commercial buildings | Commercial, industrial, and large-scale residential projects |

Which is better?

Modular construction offers faster build times and reduced labor costs by assembling pre-fabricated sections in controlled factory environments, making it ideal for projects requiring speed and cost efficiency. Steel frame construction provides superior structural strength, durability, and flexibility for architectural designs, often preferred in high-rise buildings and complex structures. The choice depends on project priorities, with modular suited for residential and light commercial use, while steel frame excels in large-scale, long-term developments.

Connection

Modular construction frequently integrates steel frame construction as a core structural component, enabling prefabricated modules to achieve enhanced durability and design flexibility. Steel frames provide the necessary strength and stability, allowing modules to be efficiently assembled off-site and transported for rapid on-site installation. This synergy reduces construction time and costs while ensuring high-quality, sustainable real estate development.

Key Terms

Structural Integrity

Steel frame construction offers superior structural integrity due to its high strength-to-weight ratio, resistance to seismic and wind forces, and durability against environmental stresses. Modular construction incorporates prefabricated steel or composite frames, ensuring consistent quality and enhanced structural stability while reducing onsite errors. Explore our detailed analysis to understand which method best suits your project's structural requirements.

Prefabrication

Steel frame construction utilizes prefabricated steel components that are manufactured off-site to ensure precision and reduce on-site labor, enhancing structural durability and efficiency. Modular construction involves assembling fully finished sections, or modules, off-site in a factory setting, which accelerates project timelines and minimizes waste. Explore detailed comparisons of prefabrication benefits in steel frame and modular construction for optimized building solutions.

On-site Assembly

Steel frame construction requires skilled labor for welding and bolting steel components, which can extend on-site assembly time but ensures strong structural integrity. Modular construction significantly reduces on-site assembly duration by delivering pre-fabricated, factory-built modules that are quickly connected on-site, minimizing weather-related delays. Discover the key differences and benefits of both methods to optimize your building project.

Source and External Links

What Is Steel Frame Construction? - This webpage explains steel frame construction, its techniques, advantages, and modern applications, including welded, bolted, and light gauge steel framing methods.

Pros and Cons Of Steel Frames - This article discusses the pros and cons of steel frames, including their use in industrial and commercial settings, and highlights techniques like light gauge, bolted, and fabricated steel frames.

Structural Steel Framing - This webpage provides an overview of structural steel framing, highlighting its durability, reliability, and cost-effectiveness for various building projects.

dowidth.com

dowidth.com