Micro-fulfillment centers optimize urban logistics by enabling rapid order processing through automated systems within compact spaces, reducing delivery times and operational costs. Pop-up distribution points offer flexible, temporary locations to manage demand spikes and expand service coverage without long-term infrastructure investments. Explore how these innovative solutions transform supply chain efficiency and customer satisfaction.

Why it is important

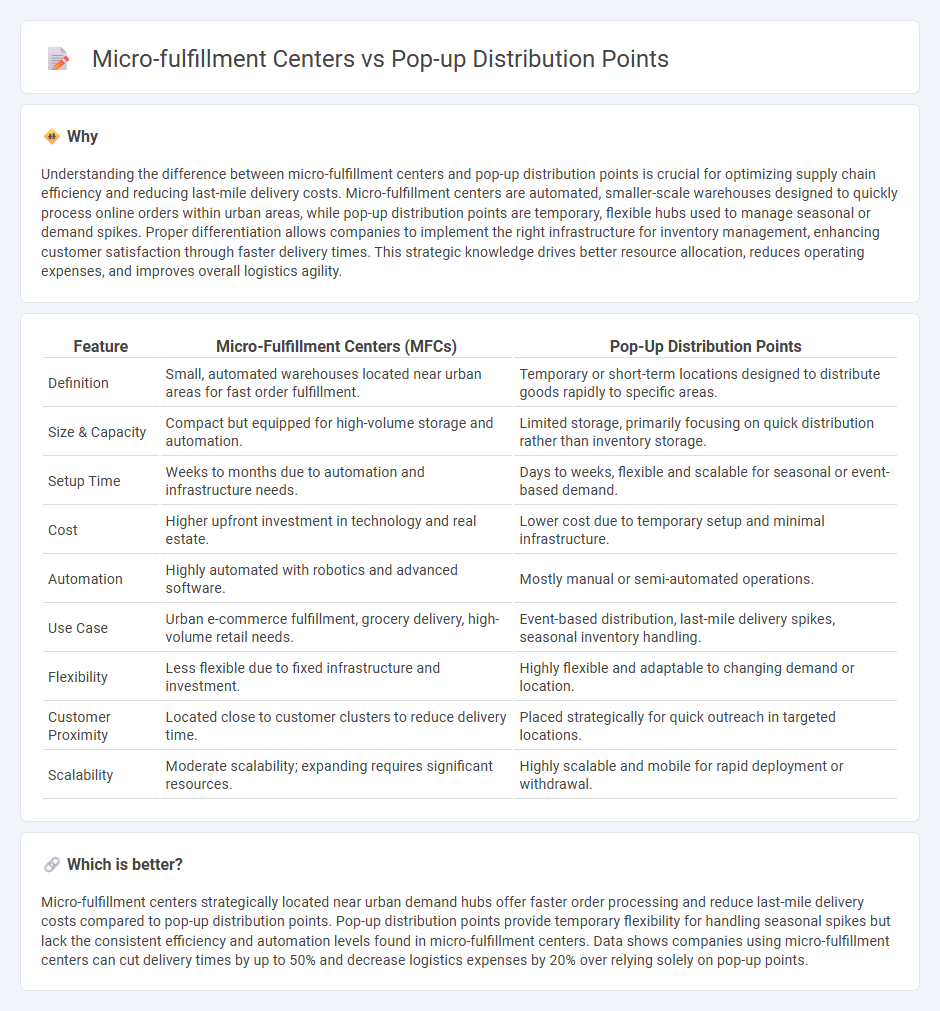

Understanding the difference between micro-fulfillment centers and pop-up distribution points is crucial for optimizing supply chain efficiency and reducing last-mile delivery costs. Micro-fulfillment centers are automated, smaller-scale warehouses designed to quickly process online orders within urban areas, while pop-up distribution points are temporary, flexible hubs used to manage seasonal or demand spikes. Proper differentiation allows companies to implement the right infrastructure for inventory management, enhancing customer satisfaction through faster delivery times. This strategic knowledge drives better resource allocation, reduces operating expenses, and improves overall logistics agility.

Comparison Table

| Feature | Micro-Fulfillment Centers (MFCs) | Pop-Up Distribution Points |

|---|---|---|

| Definition | Small, automated warehouses located near urban areas for fast order fulfillment. | Temporary or short-term locations designed to distribute goods rapidly to specific areas. |

| Size & Capacity | Compact but equipped for high-volume storage and automation. | Limited storage, primarily focusing on quick distribution rather than inventory storage. |

| Setup Time | Weeks to months due to automation and infrastructure needs. | Days to weeks, flexible and scalable for seasonal or event-based demand. |

| Cost | Higher upfront investment in technology and real estate. | Lower cost due to temporary setup and minimal infrastructure. |

| Automation | Highly automated with robotics and advanced software. | Mostly manual or semi-automated operations. |

| Use Case | Urban e-commerce fulfillment, grocery delivery, high-volume retail needs. | Event-based distribution, last-mile delivery spikes, seasonal inventory handling. |

| Flexibility | Less flexible due to fixed infrastructure and investment. | Highly flexible and adaptable to changing demand or location. |

| Customer Proximity | Located close to customer clusters to reduce delivery time. | Placed strategically for quick outreach in targeted locations. |

| Scalability | Moderate scalability; expanding requires significant resources. | Highly scalable and mobile for rapid deployment or withdrawal. |

Which is better?

Micro-fulfillment centers strategically located near urban demand hubs offer faster order processing and reduce last-mile delivery costs compared to pop-up distribution points. Pop-up distribution points provide temporary flexibility for handling seasonal spikes but lack the consistent efficiency and automation levels found in micro-fulfillment centers. Data shows companies using micro-fulfillment centers can cut delivery times by up to 50% and decrease logistics expenses by 20% over relying solely on pop-up points.

Connection

Micro-fulfillment centers and pop-up distribution points enhance urban logistics by enabling faster order processing and last-mile delivery within limited spaces. These facilities utilize advanced automation and data analytics to optimize inventory management, reduce transportation costs, and meet growing e-commerce demand. Their strategic placement in high-density areas improves supply chain efficiency and customer satisfaction through expedited service.

Key Terms

Temporary warehousing

Pop-up distribution points provide temporary warehousing solutions that allow retailers to quickly respond to demand spikes and seasonal trends without significant long-term investment. Micro-fulfillment centers, while more permanent, optimize last-mile delivery efficiency through automation and strategic urban placement but involve higher setup costs. Explore the advantages and strategic applications of these models to enhance your supply chain agility.

Automated picking systems

Pop-up distribution points offer temporary, flexible locations for order pickups, ideal for rapid urban fulfillment but typically with limited inventory and basic manual sorting. Micro-fulfillment centers leverage automated picking systems, such as robotic arms and conveyor belts, to enhance order accuracy and speed, enabling efficient handling of high order volumes in compact urban warehouses. Explore how automated picking technology revolutionizes last-mile logistics by visiting advanced micro-fulfillment solutions.

Last-mile delivery

Pop-up distribution points enhance last-mile delivery by providing flexible, temporary locations for quick order pickups closer to consumers, reducing delivery times and costs. Micro-fulfillment centers are compact, automated warehouses situated near urban areas, enabling faster order processing and higher inventory availability for e-commerce fulfillment. Explore how integrating these solutions optimizes last-mile logistics for improved customer satisfaction and operational efficiency.

Source and External Links

The Rise of Pop-Up Distribution Operations - Pop-up distribution centers are temporary, flexible fulfillment facilities that bring products closer to customers, enabling brands to scale quickly, reduce capital commitment, and respond efficiently to fluctuating demand and regional market testing.

Pop-Up Distribution Centers - To Solve Warehousing Challenges - These centers are on-demand, pay-for-use rental spaces centrally located near target consumers, helping businesses manage spikes in demand and supply chain disruptions by offering temporary warehousing solutions.

Pop-Up Warehousing: Definition, Risks, and Benefits - Pop-up warehousing uses temporary space to quickly adapt to seasonal demand and inventory fluctuations, providing a cost-effective, scalable micro-fulfillment solution that avoids long-term facility commitments.

dowidth.com

dowidth.com